Sandblasting sand consists of sharp, angular grains designed to aggressively clean surfaces by removing rust, paint, and other contaminants, providing a smooth finish without excessive abrasion. Masonry sand, with its fine, rounded particles, is primarily used for mixing concrete and mortar, offering better workability and a consistent texture but lacks the hardness needed for effective sandblasting. Choosing between sandblasting sand and masonry sand depends on the application, as sandblasting sand withstands high-pressure blasting equipment, while masonry sand performs best in construction projects for bonding and leveling surfaces.

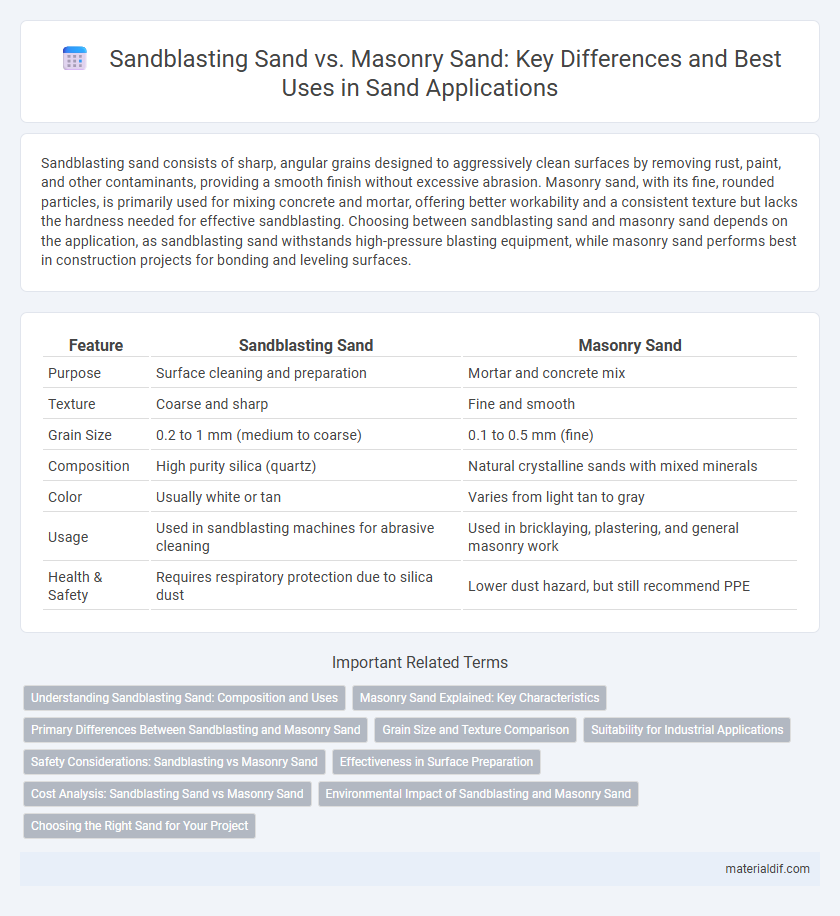

Table of Comparison

| Feature | Sandblasting Sand | Masonry Sand |

|---|---|---|

| Purpose | Surface cleaning and preparation | Mortar and concrete mix |

| Texture | Coarse and sharp | Fine and smooth |

| Grain Size | 0.2 to 1 mm (medium to coarse) | 0.1 to 0.5 mm (fine) |

| Composition | High purity silica (quartz) | Natural crystalline sands with mixed minerals |

| Color | Usually white or tan | Varies from light tan to gray |

| Usage | Used in sandblasting machines for abrasive cleaning | Used in bricklaying, plastering, and general masonry work |

| Health & Safety | Requires respiratory protection due to silica dust | Lower dust hazard, but still recommend PPE |

Understanding Sandblasting Sand: Composition and Uses

Sandblasting sand primarily consists of angular silica grains with high hardness and purity, making it ideal for abrasive cleaning and surface preparation in industrial applications. Its abrasive quality ensures efficient removal of rust, paint, and contaminants from metal, glass, and concrete surfaces. Unlike masonry sand, which is finer and rounded for mortar and concrete mix, sandblasting sand is specifically processed to withstand high-pressure blasting systems.

Masonry Sand Explained: Key Characteristics

Masonry sand features fine, smooth grains that provide excellent workability and a polished finish, making it ideal for brick, block, and stone masonry projects. Its clean, well-rounded particles promote strong bonding when mixed with cement and mortar, enhancing durability and strength in construction. Unlike rough, angular sandblasting sand, masonry sand is not abrasive, ensuring a refined texture suitable for detailed masonry work.

Primary Differences Between Sandblasting and Masonry Sand

Sandblasting sand primarily consists of angular silica grains designed for abrasive cleaning and surface preparation, while masonry sand is composed of finer, smoother particles intended for construction and mortar mixes. The key difference lies in their grain shape and size, where sandblasting sand's rough texture enhances abrasion, and masonry sand's softness ensures better workability in bricklaying. Additionally, sandblasting sand has higher purity and durability to withstand high-pressure blasting, unlike masonry sand, which is optimized for bonding and finishing surfaces.

Grain Size and Texture Comparison

Sandblasting sand typically features coarser grain sizes ranging from 0.2 to 1.0 millimeters, offering a rough and angular texture ideal for abrasive cleaning and surface preparation. Masonry sand possesses finer grains, usually between 0.1 to 0.5 millimeters, with a smoother, rounded texture that enhances workability and finish in mortar and concrete applications. The contrasting grain sizes and textures directly influence their suitability, with sandblasting sand providing aggressive abrasion and masonry sand contributing to structural strength and smooth surfaces.

Suitability for Industrial Applications

Sandblasting sand features angular grains that are highly effective for abrasive cleaning and surface preparation in industrial applications, providing superior durability and impact resistance. Masonry sand, characterized by its finer, smoother texture, is better suited for non-abrasive tasks such as mixing mortar or plaster, where a softer, more workable material is required. Industrial environments demanding high-performance abrasion and surface roughening will benefit from sandblasting sand, while masonry sand serves well in construction processes requiring gentle adhesion and finish.

Safety Considerations: Sandblasting vs Masonry Sand

Silica sand used in sandblasting poses significant health risks due to inhalation of fine silica particles, which can cause silicosis and respiratory issues, necessitating strict personal protective equipment like respirators and ventilation controls. Masonry sand, composed of larger, less respirable particles, presents fewer airborne hazards but still requires dust control measures to prevent irritation to the skin and eyes. Both materials demand adherence to OSHA regulations and workplace safety standards to minimize exposure and ensure safe handling in industrial and construction environments.

Effectiveness in Surface Preparation

Sandblasting sand features angular grains that provide superior abrasion, making it highly effective for thorough surface preparation and paint or rust removal. Masonry sand, with its finer, smoother particles, is less abrasive and better suited for finishing tasks but offers limited effectiveness in aggressive surface etching. For optimal surface cleanliness and texture required in industrial applications, sandblasting sand outperforms masonry sand in preparation efficiency.

Cost Analysis: Sandblasting Sand vs Masonry Sand

Sandblasting sand typically incurs higher costs than masonry sand due to its superior hardness and specialized processing required for abrasive blasting. Masonry sand, commonly used for construction and landscaping, is more plentiful and less expensive, making it a cost-effective choice for nonabrasive applications. When budgeting for projects, the price per ton of sandblasting sand can be two to three times that of masonry sand, reflecting its enhanced durability and performance.

Environmental Impact of Sandblasting and Masonry Sand

Sandblasting sand, often composed of silica or industrial abrasives, poses significant environmental risks due to airborne silica dust, which can harm air quality and respiratory health. Masonry sand, typically sourced from natural riverbeds, has a lower environmental footprint but can contribute to habitat disruption and water pollution if extracted irresponsibly. Sustainable extraction practices and stringent dust control measures are essential to mitigating the ecological impact of both sand types.

Choosing the Right Sand for Your Project

Sandblasting sand is specially graded for its angular particles that provide effective abrasion and durability, making it ideal for surface preparation and cleaning applications. Masonry sand, characterized by its finer and smoother texture, is best suited for mixing mortar and finishing masonry work due to its consistent particle size and minimal impurities. Choosing the right sand depends on the project's requirements for texture, abrasion, and strength, ensuring optimal performance and finish quality.

Sandblasting Sand vs Masonry Sand Infographic

materialdif.com

materialdif.com