Green sand contains moisture, making it ideal for molding and shaping in foundry processes due to its flexibility and ability to hold form. Dry sand, on the other hand, is free of moisture, providing a firmer, more stable mold surface that enhances precision and reduces the risk of defects during metal casting. Choosing between green sand and dry sand depends on the desired balance of moldability and dimensional accuracy in manufacturing applications.

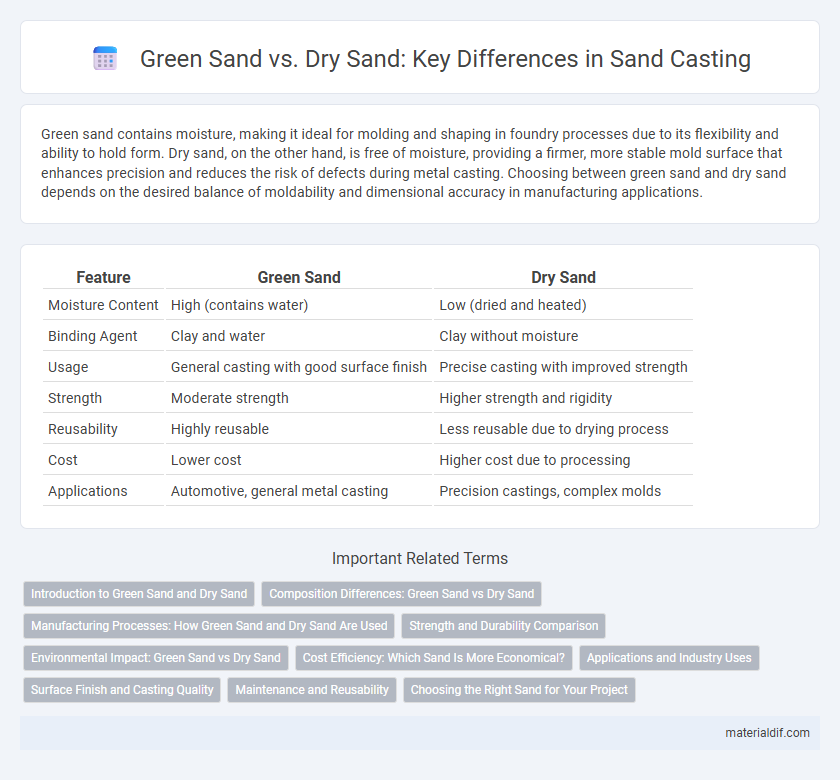

Table of Comparison

| Feature | Green Sand | Dry Sand |

|---|---|---|

| Moisture Content | High (contains water) | Low (dried and heated) |

| Binding Agent | Clay and water | Clay without moisture |

| Usage | General casting with good surface finish | Precise casting with improved strength |

| Strength | Moderate strength | Higher strength and rigidity |

| Reusability | Highly reusable | Less reusable due to drying process |

| Cost | Lower cost | Higher cost due to processing |

| Applications | Automotive, general metal casting | Precision castings, complex molds |

Introduction to Green Sand and Dry Sand

Green sand consists of a mixture of sand, clay, water, and other additives, providing excellent moldability and moisture retention for metal casting processes. Dry sand lacks moisture and is typically used in core making or as a backing material, offering better dimensional stability and surface finish. The choice between green sand and dry sand directly impacts mold strength, permeability, and the quality of the final cast product.

Composition Differences: Green Sand vs Dry Sand

Green sand primarily consists of silica sand, bentonite clay, water, and additives that maintain its moisture content, enabling moldability and plasticity. Dry sand, in contrast, contains silica sand mixed with binders like sodium silicate or organic resins and is devoid of moisture, resulting in a firmer and more rigid mold. The presence of clay and water in green sand allows for easy reshaping, whereas dry sand's composition ensures improved dimensional accuracy and surface finish in casting processes.

Manufacturing Processes: How Green Sand and Dry Sand Are Used

Green sand is widely used in metal casting due to its moisture content, which allows it to be easily molded and reused, making it ideal for producing complex shapes with high precision. Dry sand, on the other hand, undergoes a drying or baking process to remove moisture, resulting in greater strength and stability, which is crucial for castings requiring higher dimensional accuracy and surface finish. Manufacturing processes involving green sand prioritize flexibility and cost-effectiveness, while dry sand processes focus on durability and detailed casting requirements.

Strength and Durability Comparison

Green sand, composed of a mixture of sand, clay, water, and additives, offers moderate strength and durability suitable for most casting applications, while dry sand undergoes a baking process that significantly enhances its hardness and structural integrity. Dry sand molds exhibit superior strength and durability, enabling them to withstand higher metal pouring temperatures and reduce defects in intricate castings. The increased compressive strength and rigidity of dry sand contribute to improved dimensional accuracy and longer mold life compared to green sand.

Environmental Impact: Green Sand vs Dry Sand

Green sand offers a lower environmental impact compared to dry sand due to its higher moisture content, which reduces dust emissions during handling and application. The moisture in green sand also helps minimize soil erosion and sediment runoff, preserving local ecosystems. In contrast, dry sand can generate significant airborne dust, contributing to air pollution and respiratory issues, and promotes greater erosion when disturbed.

Cost Efficiency: Which Sand Is More Economical?

Green sand offers a more cost-efficient option compared to dry sand due to its moisture content, which reduces the need for additional water and binder materials, lowering overall production costs. Dry sand requires energy-intensive drying processes, increasing operational expenses and limiting cost savings. Evaluating applications where moisture control is less critical can maximize green sand's economic advantages in foundry and construction projects.

Applications and Industry Uses

Green sand, a mixture of sand, clay, water, and other additives, is predominantly used in metal casting industries for making molds due to its excellent moldability and reusability. Dry sand, cured through baking or chemical binders, finds applications in precision casting and core making where rigidity and dimensional accuracy are critical. Both types serve distinct roles in foundries, with green sand favored for general casting and dry sand preferred in producing complex or high-quality castings.

Surface Finish and Casting Quality

Green sand molds provide a smoother surface finish due to their moisture content, which helps produce finer details and reduces casting defects such as sand inclusions and blowholes. Dry sand molds, being cured and harder, tend to offer better dimensional accuracy and can handle more complex geometries but may result in a rougher surface finish. The choice between green sand and dry sand significantly impacts casting quality, balancing surface smoothness with structural integrity depending on the application requirements.

Maintenance and Reusability

Green sand requires regular moisture monitoring and consistent mixing to maintain optimal casting properties, with its clay and water content allowing for easier recyclability through resieving and reconditioning. Dry sand, being moisture-free, demands careful control of drying processes to prevent degradation, but it offers limited reusability due to binder burnout during the drying phase. Proper maintenance of green sand extends its lifespan and reduces waste, while dry sand's reusability is more constrained, influencing cost-effectiveness in foundry operations.

Choosing the Right Sand for Your Project

Green sand, composed of sand, clay, water, and other additives, offers excellent moldability and moisture retention, making it ideal for foundry and construction projects requiring flexibility and quick shaping. Dry sand, free of moisture, is preferred for tasks demanding high strength and stability, such as concrete mixing and dry mortar applications, where water content can weaken the final product. Selecting the appropriate sand type depends on project requirements for moisture control, structural integrity, and workability to ensure optimal performance.

Green sand vs Dry sand Infographic

materialdif.com

materialdif.com