Silica sand mining involves extracting high-purity sand primarily composed of silicon dioxide, which is ideal for industrial applications such as glassmaking and water filtration due to its uniform grain size and chemical stability. Dune sand mining targets loose, wind-deposited sands often less suitable for commercial use because of their irregular grain shapes and lower silica content, leading to challenges in construction and manufacturing. Environmental concerns also differ as silica sand mining typically occurs near riverbeds, potentially impacting aquatic ecosystems, while dune sand extraction can cause desertification and habitat disruption.

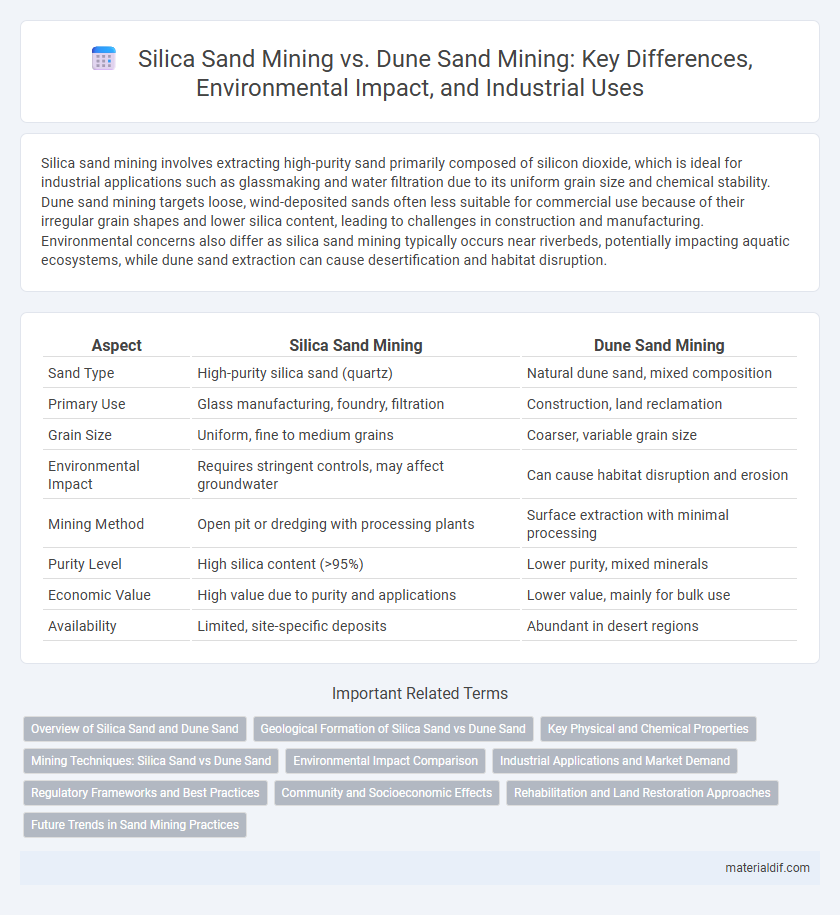

Table of Comparison

| Aspect | Silica Sand Mining | Dune Sand Mining |

|---|---|---|

| Sand Type | High-purity silica sand (quartz) | Natural dune sand, mixed composition |

| Primary Use | Glass manufacturing, foundry, filtration | Construction, land reclamation |

| Grain Size | Uniform, fine to medium grains | Coarser, variable grain size |

| Environmental Impact | Requires stringent controls, may affect groundwater | Can cause habitat disruption and erosion |

| Mining Method | Open pit or dredging with processing plants | Surface extraction with minimal processing |

| Purity Level | High silica content (>95%) | Lower purity, mixed minerals |

| Economic Value | High value due to purity and applications | Lower value, mainly for bulk use |

| Availability | Limited, site-specific deposits | Abundant in desert regions |

Overview of Silica Sand and Dune Sand

Silica sand consists primarily of silicon dioxide (SiO2) with a high quartz content, making it ideal for glassmaking, foundry molds, and hydraulic fracturing due to its uniform grain size and chemical purity. Dune sand, formed by wind-blown sediments in desert environments, is typically finer and more rounded, lacking the angularity and silica concentration required for industrial applications. Silica sand mining targets high-purity deposits for commercial use, whereas dune sand mining is limited by the sand's physical properties and environmental concerns related to fragile ecosystems.

Geological Formation of Silica Sand vs Dune Sand

Silica sand originates from the weathering and erosion of quartz-rich rocks, resulting in sand grains predominantly composed of silicon dioxide with high purity and uniform grain size. Dune sand forms through the wind-driven accumulation and sorting of loose, fine particles, often consisting of a mix of minerals including quartz but with variable composition and coarser grain distribution. Geological formation of silica sand typically involves sedimentary processes in stable environments like riverbeds or beaches, while dune sand results from aeolian processes in arid or coastal regions with dynamic wind patterns.

Key Physical and Chemical Properties

Silica sand mining yields sand with high quartz content, low impurities, and angular grains ideal for industrial use, while dune sand mining produces finer, rounded grains with less quartz and more feldspar or carbonate minerals. The chemical stability of silica sand is superior, featuring predominantly SiO2 with minimal iron oxide or clay contaminants, contrasting with dune sand's more variable mineral composition and higher moisture retention. Physical properties such as grain size distribution, hardness (7 on Mohs scale for silica sand), and low silt content make silica sand more efficient for construction and glass manufacturing compared to dune sand's softer, less durable particle characteristics.

Mining Techniques: Silica Sand vs Dune Sand

Silica sand mining employs advanced methods such as hydraulic mining and dredging to extract high-purity quartz grains essential for industrial applications, ensuring minimal contamination and maintaining grain size uniformity. In contrast, dune sand mining typically involves surface excavation using bulldozers and scrapers, targeting loosely packed sand primarily used for construction, with less emphasis on grain purity or size consistency. These differing techniques reflect the distinct geological characteristics and end-use requirements of silica and dune sands.

Environmental Impact Comparison

Silica sand mining typically involves significant land disturbance, water usage, and chemical processing, leading to habitat destruction and potential groundwater contamination. Dune sand mining, while generally less chemically intensive, causes severe erosion, loss of biodiversity, and destabilization of natural dune ecosystems. Both practices contribute to dust pollution and long-term ecological imbalance, but silica sand mining poses higher risks of toxic runoff and industrial waste accumulation.

Industrial Applications and Market Demand

Silica sand mining dominates industrial applications due to its high purity and consistent grain size, making it essential for glass manufacturing, foundry molds, and hydraulic fracturing. Dune sand, with its irregular grain shape and lower silica content, is less favored in high-precision industries but remains in demand for construction and land reclamation projects. Market trends indicate a growing preference for silica sand driven by stringent quality standards in manufacturing and the expanding energy sector.

Regulatory Frameworks and Best Practices

Silica sand mining is typically governed by stringent regulatory frameworks due to its industrial applications, emphasizing environmental impact assessments, restoration plans, and dust control measures. Dune sand mining faces stricter restrictions or bans in many regions to prevent ecosystem disruption, erosion, and habitat loss. Best practices for both involve continuous monitoring, sustainable extraction limits, and community engagement to minimize ecological and social impacts.

Community and Socioeconomic Effects

Silica sand mining often generates significant employment opportunities and infrastructure development, enhancing local economies and community welfare, but can also lead to displacement and health risks from silica dust exposure. Dune sand mining typically impacts fragile ecosystems and traditional livelihoods, causing soil erosion and reduced agricultural productivity, which undermine long-term socioeconomic stability. Both practices require stringent environmental and social safeguards to balance economic benefits with the preservation of community wellbeing.

Rehabilitation and Land Restoration Approaches

Silica sand mining involves deep extraction processes that often require extensive rehabilitation, including soil stabilization, re-vegetation with native species, and water management to restore ecosystem balance. In contrast, dune sand mining focuses on shallower removal with emphasis on reshaping dunes, controlling erosion, and re-establishing vegetation to prevent desertification. Both approaches prioritize land restoration techniques tailored to specific environmental impacts and regional biodiversity to ensure sustainable land use post-mining.

Future Trends in Sand Mining Practices

Silica sand mining is expected to advance through sustainable extraction technologies and increased automation to meet industrial demand for high-purity sand in glassmaking and electronics. Dune sand mining, facing stricter environmental regulations, will likely shift towards more controlled surface mining techniques to mitigate ecological impact and preserve natural landscapes. Future trends emphasize the integration of remote sensing and AI-driven monitoring systems to optimize resource management and reduce environmental damage in both silica and dune sand mining sectors.

Silica sand mining vs Dune sand mining Infographic

materialdif.com

materialdif.com