Pit sand has a coarse texture with sharp edges, making it ideal for concrete work due to better binding properties. Sea sand contains salt and fine particles that can weaken concrete strength and cause corrosion in metal reinforcements. For construction projects, pit sand is preferred over sea sand to ensure durability and structural integrity.

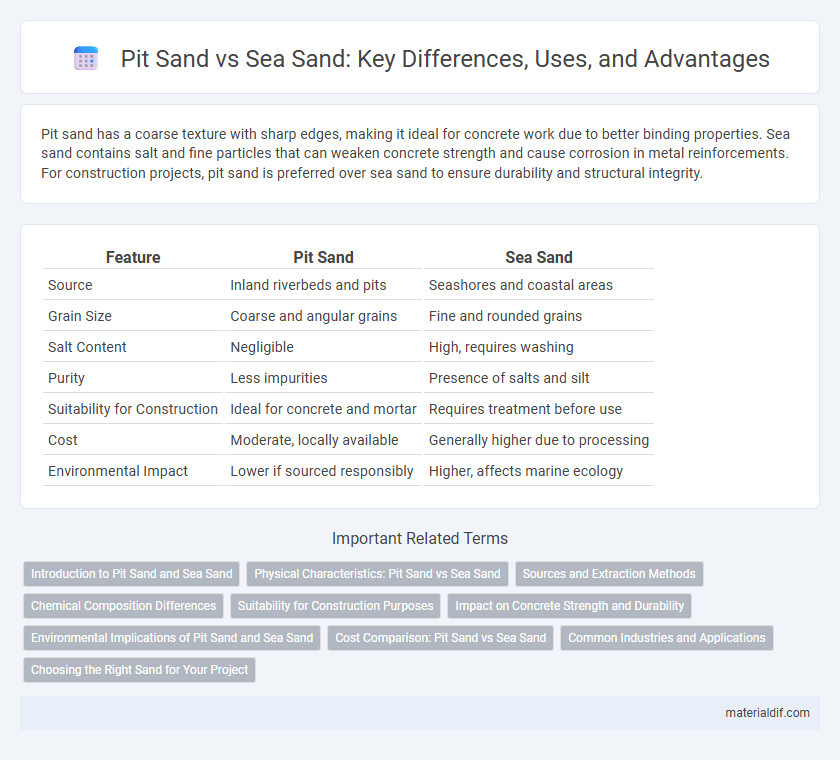

Table of Comparison

| Feature | Pit Sand | Sea Sand |

|---|---|---|

| Source | Inland riverbeds and pits | Seashores and coastal areas |

| Grain Size | Coarse and angular grains | Fine and rounded grains |

| Salt Content | Negligible | High, requires washing |

| Purity | Less impurities | Presence of salts and silt |

| Suitability for Construction | Ideal for concrete and mortar | Requires treatment before use |

| Cost | Moderate, locally available | Generally higher due to processing |

| Environmental Impact | Lower if sourced responsibly | Higher, affects marine ecology |

Introduction to Pit Sand and Sea Sand

Pit sand is coarse, angular, and has high strength, making it ideal for concrete construction and plastering work. Sea sand is smooth, rounded, and contains salts and impurities that require proper washing before use to prevent corrosion and reduce durability risks. Understanding these fundamental differences is crucial for selecting the appropriate sand type based on construction needs and environmental conditions.

Physical Characteristics: Pit Sand vs Sea Sand

Pit sand exhibits angular, coarse grains with rough texture, promoting better bond strength in concrete, whereas sea sand contains rounded, fine grains due to prolonged water action, resulting in lower bonding capacity. The higher silt content and salt presence in sea sand can cause durability issues like corrosion in reinforced concrete, unlike the cleaner pit sand that enhances structural integrity. Grain size distribution and surface texture are critical factors differentiating the physical characteristics of pit sand from sea sand in construction applications.

Sources and Extraction Methods

Pit sand is sourced from soil deposits found in pits or riverbeds, primarily extracted through manual digging or mechanized excavation, resulting in coarse particles ideal for construction. Sea sand is obtained from the seabed by dredging, involving the use of suction or grab dredgers to collect finer, salt-laden sand that requires washing to remove impurities. The extraction methods significantly influence the physical properties and suitability of sand types for specific building applications.

Chemical Composition Differences

Pit sand typically contains higher iron oxide content, giving it a reddish hue, while sea sand has more sodium chloride due to its marine origin. The chemical composition of pit sand includes significant amounts of silica (SiO2), alumina (Al2O3), and iron oxides, making it less soluble and more suitable for construction purposes. Sea sand's chloride content can cause corrosion in reinforced concrete, requiring thorough washing before use to reduce chemical impurities.

Suitability for Construction Purposes

Pit sand exhibits angular grains and rough texture, providing superior bonding strength and stability in concrete and mortar compared to sea sand. Sea sand contains high salt content, especially chlorides, which can cause corrosion of steel reinforcement and reduce structural durability. For construction purposes, pit sand is generally preferred due to its cleanliness, strength-enhancing properties, and minimal impact on concrete longevity.

Impact on Concrete Strength and Durability

Pit sand, characterized by its coarse texture and angular grains, enhances concrete strength and durability by improving interlocking and bonding with cement paste. Sea sand contains salt and fine particles that can cause corrosion in steel reinforcement, significantly reducing concrete longevity and structural integrity over time. Choosing pit sand over sea sand minimizes the risk of chloride-induced corrosion, ensuring higher concrete performance and extended service life.

Environmental Implications of Pit Sand and Sea Sand

Pit sand extraction results in significant land degradation and loss of fertile topsoil, disrupting local ecosystems and reducing agricultural productivity. Sea sand harvesting leads to coastal erosion, marine habitat destruction, and increased turbidity, harming aquatic biodiversity and fisheries. Sustainable management practices are essential to mitigate environmental damage caused by both pit sand and sea sand exploitation.

Cost Comparison: Pit Sand vs Sea Sand

Pit sand is generally more cost-effective than sea sand due to its easy accessibility and lower processing requirements. Sea sand involves additional expenses for desalination and transportation, increasing its overall cost. Construction projects typically prefer pit sand to minimize budget while ensuring material quality.

Common Industries and Applications

Pit sand, characterized by its coarse texture and angular grains, is extensively used in construction industries for concrete preparation and brick masonry due to its superior bonding properties. Sea sand, containing finer and smoother particles with higher salt content, is primarily utilized in industries like glass manufacturing and road base layers but requires thorough washing before use in concrete to prevent steel corrosion. Both types of sand serve crucial roles in manufacturing sectors, with pit sand favored for structural applications and sea sand preferred for specialized industrial processes.

Choosing the Right Sand for Your Project

Pit sand has angular grains with coarse texture, making it ideal for construction projects requiring strong bonding and durability, such as concrete and masonry work. Sea sand contains salt and fine, rounded grains that may affect the strength and longevity of structures unless properly washed and treated. Selecting pit sand ensures better structural integrity for most construction applications, while sea sand can be used for non-structural or decorative purposes after proper processing.

Pit Sand vs Sea Sand Infographic

materialdif.com

materialdif.com