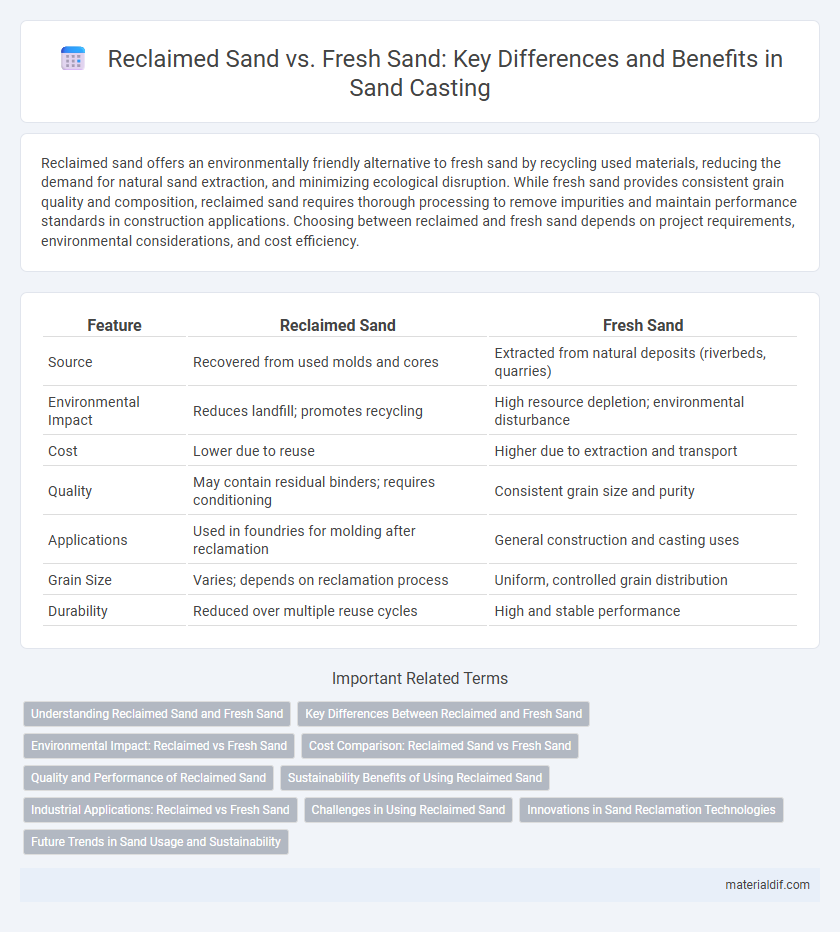

Reclaimed sand offers an environmentally friendly alternative to fresh sand by recycling used materials, reducing the demand for natural sand extraction, and minimizing ecological disruption. While fresh sand provides consistent grain quality and composition, reclaimed sand requires thorough processing to remove impurities and maintain performance standards in construction applications. Choosing between reclaimed and fresh sand depends on project requirements, environmental considerations, and cost efficiency.

Table of Comparison

| Feature | Reclaimed Sand | Fresh Sand |

|---|---|---|

| Source | Recovered from used molds and cores | Extracted from natural deposits (riverbeds, quarries) |

| Environmental Impact | Reduces landfill; promotes recycling | High resource depletion; environmental disturbance |

| Cost | Lower due to reuse | Higher due to extraction and transport |

| Quality | May contain residual binders; requires conditioning | Consistent grain size and purity |

| Applications | Used in foundries for molding after reclamation | General construction and casting uses |

| Grain Size | Varies; depends on reclamation process | Uniform, controlled grain distribution |

| Durability | Reduced over multiple reuse cycles | High and stable performance |

Understanding Reclaimed Sand and Fresh Sand

Reclaimed sand refers to sand that has been recovered and processed from previously used construction or industrial materials, ensuring sustainability by reducing the need for fresh extraction. Fresh sand, typically sourced from natural riverbeds, quarries, or marine environments, offers superior granularity and consistency but often involves ecological disruption. Understanding the differences in particle size distribution, cleanliness, and application suitability is crucial for optimizing construction quality and environmental impact management.

Key Differences Between Reclaimed and Fresh Sand

Reclaimed sand is collected from previously used construction materials and processed for reuse, resulting in environmental benefits and cost savings compared to fresh sand, which is directly mined from natural sources. Fresh sand typically offers higher purity and consistency in grain size but contributes to resource depletion and habitat disruption. The choice between reclaimed and fresh sand depends on project requirements, sustainability goals, and material availability.

Environmental Impact: Reclaimed vs Fresh Sand

Reclaimed sand significantly reduces environmental degradation by minimizing the extraction of fresh sand from natural sources such as riverbeds and beaches, thereby preserving aquatic ecosystems and preventing land erosion. The reuse of reclaimed sand lowers the carbon footprint associated with mining, transportation, and processing activities tied to fresh sand production. Utilizing reclaimed sand promotes sustainable construction practices by decreasing habitat destruction and conserving non-renewable natural resources.

Cost Comparison: Reclaimed Sand vs Fresh Sand

Reclaimed sand significantly reduces material costs compared to fresh sand, as it is recycled from used construction debris and industrial processes, minimizing the need for quarrying new resources. Fresh sand involves higher expenses due to extraction, processing, transportation, and environmental compliance fees, making it less economical for large-scale projects. Cost efficiency in construction is enhanced by reclaimed sand's lower price per ton, though quality variations may affect its overall value.

Quality and Performance of Reclaimed Sand

Reclaimed sand offers enhanced quality by retaining its angular shape and consistent grain size, which improves mold stability and surface finish in casting processes compared to fresh sand. Its performance is superior due to lower moisture content and reduced impurities, increasing sand recyclability and reducing defects in metal castings. Utilizing reclaimed sand also supports cost efficiency and environmental sustainability without compromising the mechanical properties required for precision foundry applications.

Sustainability Benefits of Using Reclaimed Sand

Reclaimed sand significantly reduces environmental impact by minimizing the need for quarrying fresh sand, conserving natural resources and lowering energy consumption associated with extraction and transportation. It supports sustainable construction practices by promoting circular economy principles, reducing landfill waste and preventing habitat disruption. Using reclaimed sand also helps maintain local biodiversity and mitigates soil erosion, contributing to long-term ecological balance.

Industrial Applications: Reclaimed vs Fresh Sand

Reclaimed sand offers a sustainable alternative to fresh sand in industrial applications such as foundry molding and construction, reducing the demand for natural resources while maintaining adequate performance. Fresh sand provides consistent grain size and purity, crucial for high-quality casting and concrete production where material uniformity impacts final strength and durability. Industries increasingly prefer reclaimed sand for eco-friendly processes but often rely on fresh sand to meet stringent specifications and product standards.

Challenges in Using Reclaimed Sand

Reclaimed sand often contains impurities such as residual binders, contaminants, and fines that can reduce its strength and compromise the quality of new molds in foundry operations. Variability in particle size distribution and moisture content presents difficulties in maintaining consistent casting properties, leading to defects like poor surface finish or dimensional inaccuracies. Managing effective reclamation processes requires advanced equipment and increased energy consumption, impacting operational costs and environmental sustainability.

Innovations in Sand Reclamation Technologies

Innovations in sand reclamation technologies have significantly enhanced the efficiency and sustainability of using reclaimed sand compared to fresh sand in construction and foundry applications. Advanced processes such as thermal reclamation, mechanical attrition, and chemical treatments enable the removal of binders and contaminants, restoring sand to near-original quality while reducing environmental impact and cost. These cutting-edge reclamation methods support the circular economy by minimizing raw sand extraction and promoting resource conservation.

Future Trends in Sand Usage and Sustainability

Reclaimed sand is gaining traction as sustainable future trends prioritize reducing environmental impact and conserving natural resources. Advances in recycling technologies enable higher purity and quality of reclaimed sand, making it a viable alternative to fresh sand in construction and manufacturing. The growing demand for eco-friendly building materials drives investment in reclaimed sand processing, aligning with global sustainability goals and circular economy principles.

Reclaimed sand vs Fresh sand Infographic

materialdif.com

materialdif.com