Crushed sand is manufactured by mechanically crushing rocks, resulting in angular particles that offer better interlocking and strength in construction applications compared to pit sand, which is naturally occurring with rounded grains. Pit sand has higher moisture content and less durability, making it less suitable for high-strength concrete but ideal for plastering due to its smooth texture. Selecting between crushed and pit sand depends on project requirements, with crushed sand favored for structural work and pit sand often used in masonry and finishing.

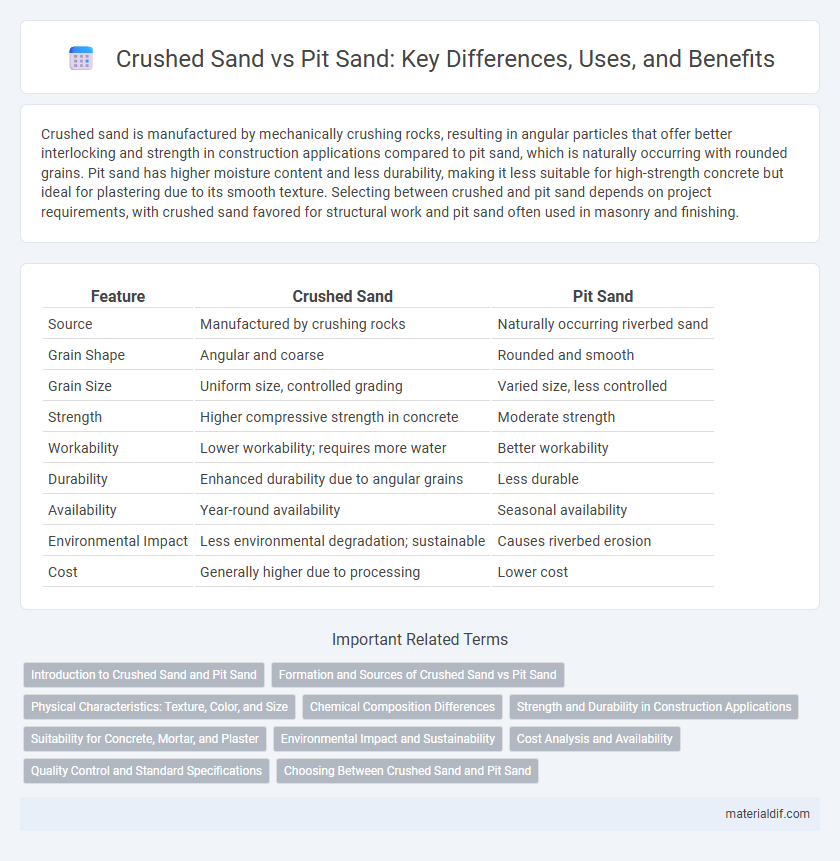

Table of Comparison

| Feature | Crushed Sand | Pit Sand |

|---|---|---|

| Source | Manufactured by crushing rocks | Naturally occurring riverbed sand |

| Grain Shape | Angular and coarse | Rounded and smooth |

| Grain Size | Uniform size, controlled grading | Varied size, less controlled |

| Strength | Higher compressive strength in concrete | Moderate strength |

| Workability | Lower workability; requires more water | Better workability |

| Durability | Enhanced durability due to angular grains | Less durable |

| Availability | Year-round availability | Seasonal availability |

| Environmental Impact | Less environmental degradation; sustainable | Causes riverbed erosion |

| Cost | Generally higher due to processing | Lower cost |

Introduction to Crushed Sand and Pit Sand

Crushed sand is manufactured by mechanically crushing rocks, resulting in angular particles with a rough texture and high strength, making it ideal for concrete and masonry work. Pit sand is naturally occurring, extracted from riverbeds or pits, characterized by its smooth, rounded grains and high silica content, which enhances workability but reduces strength compared to crushed sand. The choice between crushed and pit sand depends on construction requirements, including strength, workability, and availability.

Formation and Sources of Crushed Sand vs Pit Sand

Crushed sand is produced by mechanically breaking down hard rocks like granite, basalt, or limestone through crushing machines, resulting in angular particles with rough surfaces ideal for concrete and construction purposes. Pit sand, also known as river sand, is naturally formed by weathering and erosion of rocks and is typically collected from riverbeds or pits, characterized by smooth, rounded grains due to prolonged water transport. The key distinction lies in their origin: crushed sand originates from rock crushing plants while pit sand is directly harvested from natural deposits, influencing their texture, particle shape, and suitability for various construction applications.

Physical Characteristics: Texture, Color, and Size

Crushed sand features angular particles with a rough texture, predominantly light gray in color, and a consistent grain size ranging from 4.75 mm to fine particles. Pit sand has smooth, rounded grains with a more uniform size distribution, appearing yellowish to brown due to natural weathering. The angularity of crushed sand enhances bonding in concrete, while pit sand's natural smoothness favors workability and finish.

Chemical Composition Differences

Crushed sand primarily consists of quartz, feldspar, and mica, exhibiting higher silica content compared to pit sand, which often contains more clay and organic impurities. The chemical composition of crushed sand shows a low percentage of calcium carbonate, enhancing its durability and strength in construction applications. Pit sand's higher iron oxide and clay content can affect its color and bonding properties, making it less ideal for high-strength concrete.

Strength and Durability in Construction Applications

Crushed sand offers higher strength and durability in construction compared to pit sand due to its angular particles and better mechanical interlocking. The angular shape of crushed sand improves bonding with cement, resulting in enhanced compressive strength and reduced permeability. Pit sand, being naturally smooth and rounded, often leads to lower strength and durability in structural applications.

Suitability for Concrete, Mortar, and Plaster

Crushed sand, with its angular particles and rough texture, offers superior bonding strength and is highly suitable for concrete, providing enhanced durability and load-bearing properties compared to pit sand. Pit sand features naturally rounded grains ideal for mortar and plaster applications due to its smooth texture, which ensures better workability and finish quality. Selecting the right sand type depends on the specific application requirements, balancing strength needs in concrete with smoothness and ease of finishing in mortar and plaster.

Environmental Impact and Sustainability

Crushed sand, derived from mechanically crushed rocks, has a lower environmental impact compared to pit sand, which is extracted from riverbeds causing significant ecosystem disruption and riverbank erosion. The sustainability of crushed sand is enhanced by its ability to be produced near construction sites, reducing transportation emissions and conserving natural resources. Replacing pit sand with crushed sand supports sustainable construction by minimizing habitat destruction and promoting resource recycling.

Cost Analysis and Availability

Crushed sand typically incurs higher costs due to the energy-intensive crushing process and limited production sites, whereas pit sand is generally more affordable, sourced directly from riverbeds with minimal processing. Availability of pit sand fluctuates seasonally and regionally due to environmental regulations and extraction limits, while crushed sand offers more consistent supply as it is manufactured from locally available quarried rock. Cost analysis shows crushed sand adds value through controlled grain size and durability, offsetting its higher price in quality-sensitive construction projects.

Quality Control and Standard Specifications

Crushed sand undergoes rigorous quality control processes including sieve analysis, specific gravity tests, and contaminant checks to ensure conformity with IS 383 and ASTM C33 standards, offering uniform grain size and reduced impurities compared to pit sand. Pit sand, while naturally occurring and often preferred for its angular particles and high strength, requires thorough washing and grading to meet quality standards, but may contain impurities like silt and clay affecting concrete durability. Both sand types must comply with parameters such as fineness modulus, particle shape, and cleanliness to optimize performance in construction applications.

Choosing Between Crushed Sand and Pit Sand

Crushed sand offers higher strength and durability due to its angular particles and controlled grading, making it ideal for concrete and construction requiring high-quality aggregates. Pit sand, naturally rounded and smoother, provides better workability for plastering and bricklaying but may contain impurities affecting strength. Selecting between crushed sand and pit sand depends on specific application needs, balancing factors like structural requirements, finish quality, and cost efficiency.

Crushed sand vs Pit sand Infographic

materialdif.com

materialdif.com