Kiln-dried sand is heated to remove moisture, resulting in a dry, consistent texture ideal for applications requiring precise control, such as casting and construction. Moist silica sand contains natural water content, which can affect bonding and drying times in concrete and mortar mixes. Choosing kiln-dried sand enhances strength and durability by reducing the risk of shrinkage and cracking caused by excess moisture.

Table of Comparison

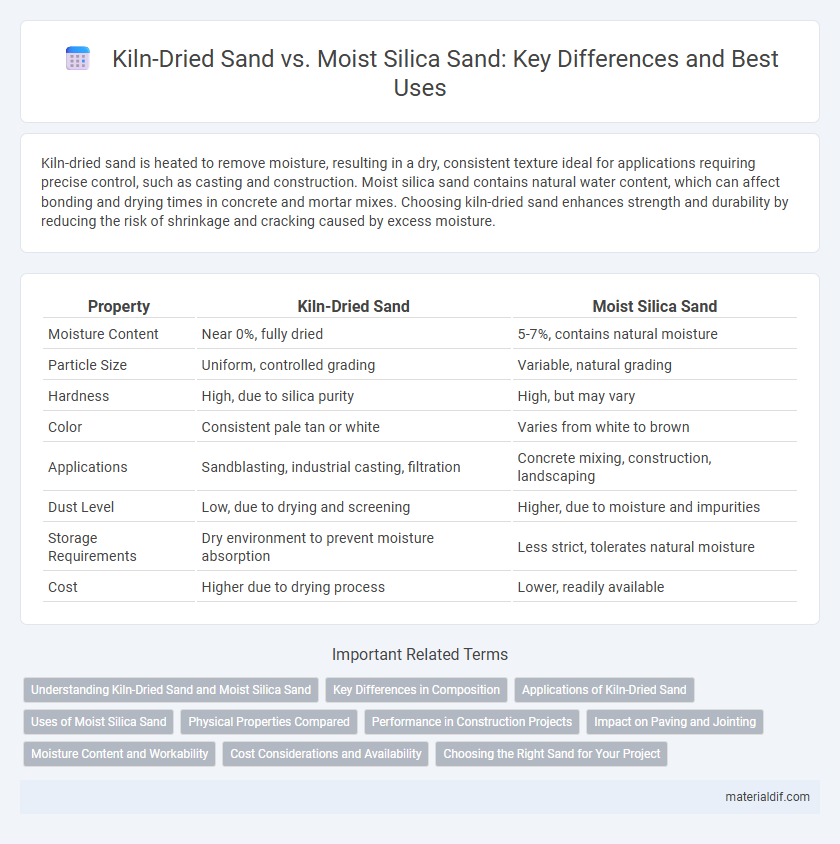

| Property | Kiln-Dried Sand | Moist Silica Sand |

|---|---|---|

| Moisture Content | Near 0%, fully dried | 5-7%, contains natural moisture |

| Particle Size | Uniform, controlled grading | Variable, natural grading |

| Hardness | High, due to silica purity | High, but may vary |

| Color | Consistent pale tan or white | Varies from white to brown |

| Applications | Sandblasting, industrial casting, filtration | Concrete mixing, construction, landscaping |

| Dust Level | Low, due to drying and screening | Higher, due to moisture and impurities |

| Storage Requirements | Dry environment to prevent moisture absorption | Less strict, tolerates natural moisture |

| Cost | Higher due to drying process | Lower, readily available |

Understanding Kiln-Dried Sand and Moist Silica Sand

Kiln-dried sand undergoes a heating process to remove moisture, resulting in a dry, consistent texture ideal for mixing and finishing applications in construction and manufacturing. Moist silica sand contains natural moisture content, making it heavier and sometimes affecting its bonding properties when mixed with cement or resin. Understanding the differences between kiln-dried and moist silica sand is crucial for selecting the right material to ensure strength, durability, and workability in concrete, casting, and industrial uses.

Key Differences in Composition

Kiln-dried sand is characterized by its low moisture content, achieved through heating in a kiln, resulting in a consistent particle size and enhanced bonding properties in construction applications. Moist silica sand contains higher natural moisture levels and variable particle sizes, which can affect its cohesion and drying time when used in concrete or mortar mixtures. The primary compositional difference lies in moisture percentage and granulometry control, directly influencing the sand's performance in industrial and building processes.

Applications of Kiln-Dried Sand

Kiln-dried sand is primarily used in industrial applications that require minimal moisture content, such as foundries and resin-bonded sand casting processes, ensuring optimal bonding strength and surface finish. Its controlled low moisture level prevents defects like gas porosity and grime in metal castings, enhancing the quality of precision components in automotive and aerospace manufacturing. Compared to moist silica sand, kiln-dried sand is preferred for applications demanding consistent grain size and purity, which improves the efficiency of sandblasting, refractory materials, and specialty glass production.

Uses of Moist Silica Sand

Moist silica sand is primarily used in hydraulic fracturing, sandblasting, and water filtration due to its optimal moisture content that improves handling and reduces dust. Its natural moisture helps prevent dust generation during transportation and application, making it ideal for industrial processes requiring minimal airborne particles. In contrast to kiln-dried sand, moist silica sand maintains stability without additional processing steps, which enhances its efficiency in construction and manufacturing sectors.

Physical Properties Compared

Kiln-dried sand features significantly lower moisture content, typically below 1%, enhancing its flowability and reducing clumping compared to moist silica sand, which contains higher natural moisture levels. The bulk density of kiln-dried sand is generally more uniform, aiding in consistent mixing and application, while moist silica sand's variable moisture impacts weight and compaction properties. Particle size distribution remains similar between both types, but the absence of moisture in kiln-dried sand improves its suitability for precision applications such as foundry molds and industrial abrasives.

Performance in Construction Projects

Kiln-dried sand offers superior consistency and lower moisture content compared to moist silica sand, leading to enhanced bonding strength and faster curing times in concrete mixes. Moist silica sand often contains variable water content, which can weaken structural integrity and increase drying time. Using kiln-dried sand in construction projects improves durability and reduces risks of shrinkage cracks and bonding failures.

Impact on Paving and Jointing

Kiln-dried sand provides superior performance in paving and jointing due to its low moisture content, enabling faster setting times and stronger bonds in mortar mixes. Moist silica sand, containing higher moisture, can delay curing and reduce joint stability, leading to potential weakening over time. The consistent dryness of kiln-dried sand helps maintain optimal joint adhesion and durability in various paving applications.

Moisture Content and Workability

Moisture content in kiln-dried sand is typically below 1%, ensuring minimal water interference during mixing and promoting consistent workability in concrete and mortar. Moist silica sand contains higher moisture levels, often ranging from 2% to 5%, which can affect the water-cement ratio and reduce the ease of mixing and finishing. Lower moisture content in kiln-dried sand results in better flow, improved compaction, and optimal setting times compared to moist silica sand.

Cost Considerations and Availability

Kiln-dried sand typically incurs higher costs due to the energy-intensive drying process that removes moisture, making it more expensive than moist silica sand. Moist silica sand is often more readily available in bulk and sourced directly from natural deposits, reducing transportation and processing expenses. Cost efficiency depends on project requirements, with kiln-dried sand favored for precision applications despite its premium price and limited availability compared to moist silica sand.

Choosing the Right Sand for Your Project

Kiln-dried sand offers low moisture content, making it ideal for concrete mixing and mortar applications requiring precise water ratios and enhanced strength. Moist silica sand retains natural moisture, which can affect the curing process and result in weaker structural integrity if not accounted for. Selecting kiln-dried sand ensures consistent performance and durability in construction, while moist silica sand suits landscaping or recreational projects where moisture control is less critical.

Kiln-dried sand vs Moist silica sand Infographic

materialdif.com

materialdif.com