Frac sand is specifically engineered for high-strength and durability to withstand extreme pressures in hydraulic fracturing processes, while filter sand is primarily used in water filtration systems to trap impurities and improve water quality. The grain size and composition of frac sand are more uniform and resistant to crushing, unlike filter sand, which is selected for its porosity and ability to promote fluid flow. Both types of sand play crucial roles in their respective industries, optimizing performance based on their unique physical properties.

Table of Comparison

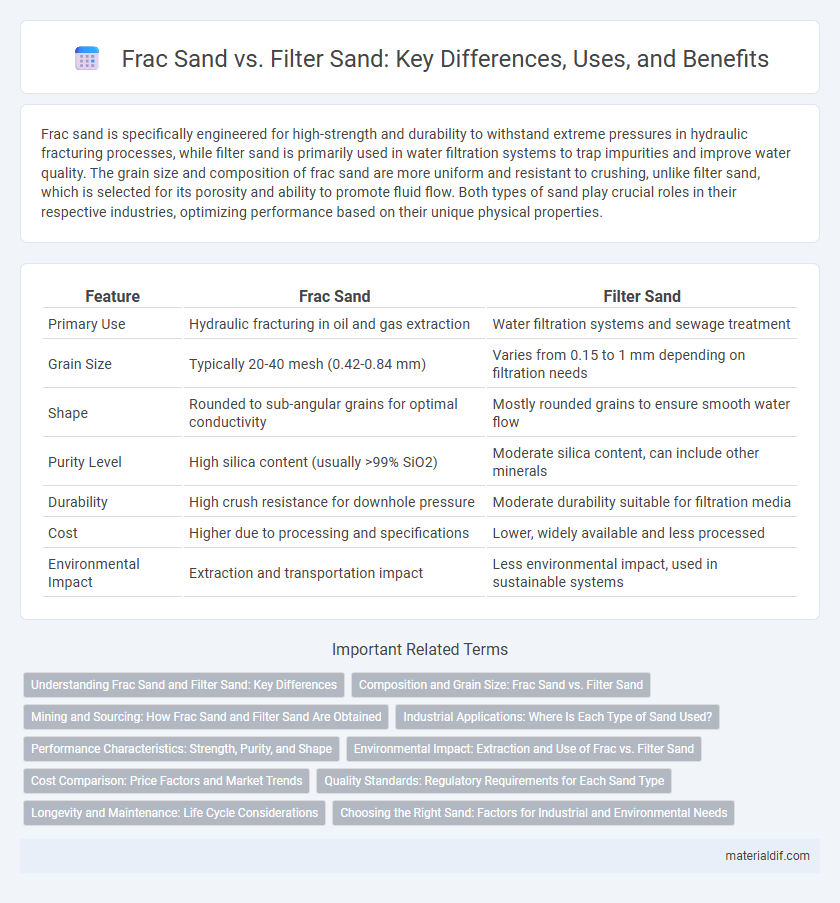

| Feature | Frac Sand | Filter Sand |

|---|---|---|

| Primary Use | Hydraulic fracturing in oil and gas extraction | Water filtration systems and sewage treatment |

| Grain Size | Typically 20-40 mesh (0.42-0.84 mm) | Varies from 0.15 to 1 mm depending on filtration needs |

| Shape | Rounded to sub-angular grains for optimal conductivity | Mostly rounded grains to ensure smooth water flow |

| Purity Level | High silica content (usually >99% SiO2) | Moderate silica content, can include other minerals |

| Durability | High crush resistance for downhole pressure | Moderate durability suitable for filtration media |

| Cost | Higher due to processing and specifications | Lower, widely available and less processed |

| Environmental Impact | Extraction and transportation impact | Less environmental impact, used in sustainable systems |

Understanding Frac Sand and Filter Sand: Key Differences

Frac sand, primarily composed of high-purity quartz, is engineered for hydraulic fracturing to prop open fractures in rock formations, enabling oil and gas extraction, while filter sand is specifically graded for water filtration systems, designed to trap particulates and improve water clarity. The granule size, shape, and crush resistance of frac sand meet stringent criteria for subsurface durability and permeability, unlike filter sand which emphasizes uniformity and mechanical stability to prevent clogging in water treatment applications. Understanding these key differences highlights the specialized properties and industry-specific applications that distinguish frac sand's role in energy production from filter sand's function in water purification.

Composition and Grain Size: Frac Sand vs. Filter Sand

Frac sand primarily consists of highly durable quartz with a uniform grain size ranging from 0.1 to 1 millimeter, optimized to withstand high pressures in hydraulic fracturing. Filter sand often contains a mix of silica and other minerals with a broader grain size distribution, typically between 0.15 and 0.85 millimeters, designed for efficient filtration and drainage. The uniformity and strength of frac sand grains are critical for maintaining fracture conductivity, whereas filter sand emphasizes permeability and sediment retention.

Mining and Sourcing: How Frac Sand and Filter Sand Are Obtained

Frac sand is primarily mined from high-purity sandstone deposits through extensive open-pit mining, ensuring uniform grain size and high silica content necessary for hydraulic fracturing. Filter sand is sourced from naturally occurring riverbeds or quarries, selected for its angular grains and consistent porosity to optimize filtration efficiency. Both types undergo rigorous processing to remove impurities, but their mining techniques differ significantly due to their distinct industrial applications.

Industrial Applications: Where Is Each Type of Sand Used?

Frac sand is primarily used in the oil and gas industry for hydraulic fracturing, providing high-purity silica sand that resists crushing and allows for optimal permeability in well formations. Filter sand, characterized by its uniform grain size and low clay content, is widely utilized in water treatment plants, swimming pools, and industrial filtration systems to effectively remove impurities. Industrial applications require frac sand for its durability and strength in subsurface environments, while filter sand is essential for maintaining clean water and fluid systems.

Performance Characteristics: Strength, Purity, and Shape

Frac sand exhibits high strength and spherical shape, optimizing its flow and durability under hydraulic fracturing pressures, with purity levels typically above 99% silica. Filter sand, designed for water filtration systems, features angular grains enhancing filtration efficiency and interlocking, with purity essential to prevent clogging but generally lower than frac sand. Strength in filter sand is sufficient for static filtration loads, while frac sand demands superior crush resistance to maintain proppant integrity.

Environmental Impact: Extraction and Use of Frac vs. Filter Sand

Frac sand extraction often involves high-impact mining techniques that result in habitat disruption, increased water consumption, and dust pollution, posing significant environmental concerns. In contrast, filter sand is typically sourced from more sustainable deposits with lower extraction footprints, supporting water treatment processes that improve environmental health by reducing contaminants. The environmental impact of frac sand is substantially higher due to intensive extraction and transport, while filter sand plays a role in enhancing water quality and minimizing pollution.

Cost Comparison: Price Factors and Market Trends

Frac sand typically commands higher prices than filter sand due to its stringent purity standards, spherical shape, and high strength required for hydraulic fracturing operations. Market trends show increased demand for frac sand from oil and gas industries, driving prices upward, while filter sand, used mainly in water filtration systems, maintains stable but lower pricing influenced by water treatment infrastructure investments. Cost factors for frac sand include transportation, mining complexity, and silica content, whereas filter sand pricing depends largely on grain size distribution and regional market availability.

Quality Standards: Regulatory Requirements for Each Sand Type

Frac sand must meet stringent quality standards including high silica content, consistent grain size, and durability to withstand hydraulic fracturing pressures, adhering to regulatory requirements such as ISO 13503-2 and API specifications. Filter sand, used in water filtration systems, is regulated to ensure uniform grain size, cleanliness, and chemical stability to prevent contamination, complying with standards like NSF/ANSI 61 and AWWA B100. Both sand types require rigorous testing for impurities and physical properties to meet industry-specific safety and performance regulations.

Longevity and Maintenance: Life Cycle Considerations

Frac sand offers high durability under extreme pressure, extending its longevity in hydraulic fracturing applications with minimal maintenance requirements. Filter sand, primarily used for water filtration, experiences slower wear but may require more frequent cleaning to maintain performance over time. Both sands' life cycles depend on grain size, composition, and operating conditions, influencing replacement intervals and overall maintenance costs.

Choosing the Right Sand: Factors for Industrial and Environmental Needs

Frac sand features high durability and uniform grain size essential for hydraulic fracturing in oil and gas extraction, while filter sand excels in porosity and particle shape, optimizing water filtration systems. Selecting the right sand depends on application-specific factors like permeability, chemical resistance, and environmental impact to ensure operational efficiency and sustainability. Industrial demands prioritize strength and purity in frac sand, whereas environmental filtration favors sand that prevents clogging and promotes contaminant removal.

Frac sand vs Filter sand Infographic

materialdif.com

materialdif.com