River sand has traditionally been preferred for construction due to its natural smoothness and fine texture, which enhances the strength and finish of concrete. M-sand, manufactured by crushing hard granite rocks, offers a more sustainable and economical alternative, with consistent particle size and less impurities. While river sand extraction can lead to environmental degradation, M-sand supports eco-friendly construction practices by reducing riverbed mining.

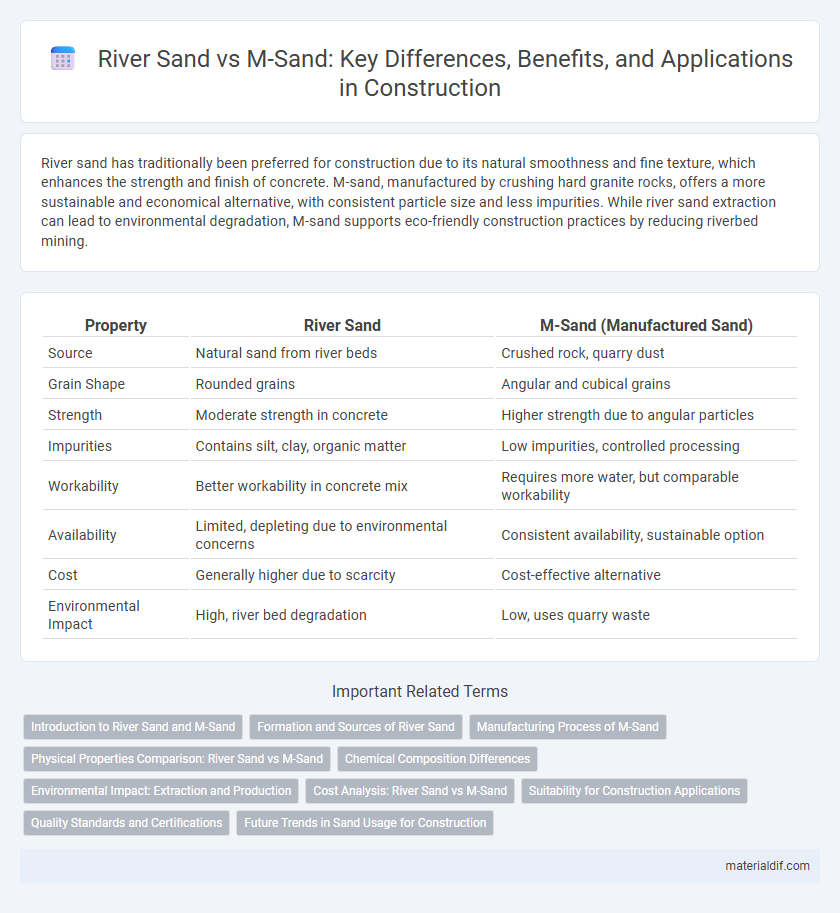

Table of Comparison

| Property | River Sand | M-Sand (Manufactured Sand) |

|---|---|---|

| Source | Natural sand from river beds | Crushed rock, quarry dust |

| Grain Shape | Rounded grains | Angular and cubical grains |

| Strength | Moderate strength in concrete | Higher strength due to angular particles |

| Impurities | Contains silt, clay, organic matter | Low impurities, controlled processing |

| Workability | Better workability in concrete mix | Requires more water, but comparable workability |

| Availability | Limited, depleting due to environmental concerns | Consistent availability, sustainable option |

| Cost | Generally higher due to scarcity | Cost-effective alternative |

| Environmental Impact | High, river bed degradation | Low, uses quarry waste |

Introduction to River Sand and M-Sand

River sand is naturally sourced from riverbeds, known for its fine texture and smooth grains, making it highly suitable for concrete and construction work due to its excellent workability. Manufactured sand (M-sand), produced by crushing hard granite rocks, presents a more uniform grain size and angular shape, providing better bonding strength in concrete mixtures. The growing environmental concerns and depletion of natural river sand reserves have increased the preference for sustainable alternatives like M-sand in modern construction projects.

Formation and Sources of River Sand

River sand forms through natural weathering and erosion of rocks upstream, transported by flowing water to riverbeds and banks, resulting in smooth, rounded grains. It is sourced primarily from mountainous and hilly regions where rivers carve through rock formations, collecting mineral particles along their course. This natural process contrasts with the manufactured production of M-sand, which is crushed from hard granite rocks in quarries.

Manufacturing Process of M-Sand

Manufactured sand (M-sand) is produced by crushing hard granite rocks in a specialized unit, resulting in angular sand particles with a controlled size distribution. This process ensures uniformity, eliminates impurities found in natural river sand, and enhances the strength and durability of construction materials. The use of jaw crushers and vibrating screens in the manufacturing process of M-sand guarantees consistent quality adhering to IS standards.

Physical Properties Comparison: River Sand vs M-Sand

River sand features a rounded grain shape and smooth texture, resulting in better workability and finish in concrete, while M-sand has angular, cubical grains that offer superior strength and bonding due to increased surface area. River sand typically exhibits lower silt content and moderate moisture absorption, whereas M-sand can have higher fines and requires proper washing to meet quality standards. The specific gravity of M-sand usually ranges between 2.6 to 2.8, slightly higher than river sand, influencing the density and durability of the concrete mix.

Chemical Composition Differences

River sand primarily consists of quartz (SiO2) with minor amounts of feldspar and mica, making it chemically stable and inert. Manufactured sand (M-sand) is produced by crushing rocks such as granite or basalt, resulting in a higher presence of silicates and sometimes metal oxides like iron oxide (Fe2O3) depending on the source material. These chemical composition differences affect the reactivity, durability, and behavior of the sand in concrete mixes and construction applications.

Environmental Impact: Extraction and Production

River sand extraction causes significant riverbed degradation and disrupts aquatic ecosystems, leading to habitat loss and increased sedimentation. Manufactured sand (M-sand) production involves crushing rocks, producing less environmental disturbance and reducing depletion of natural river resources. M-sand offers a sustainable alternative with controlled manufacturing processes that minimize ecological damage and support responsible construction practices.

Cost Analysis: River Sand vs M-Sand

River sand typically incurs higher costs due to extraction regulations, transportation expenses, and limited availability, making it a more expensive option for construction projects. Manufactured sand (M-sand) offers a cost-effective alternative with consistent quality, lower transportation costs, and reduced environmental impact, leading to substantial savings in bulk material procurement. Price variations depend on regional factors, but M-sand generally presents a more economical choice without compromising structural integrity.

Suitability for Construction Applications

River sand exhibits natural smoothness and rounded particles, making it ideal for plastering and finishing work in construction. M-sand, manufactured by crushing hard granite rocks, offers angular and consistent particle size, enhancing its suitability for concrete and masonry applications due to improved bonding. Choosing between river sand and M-sand depends on specific structural requirements, cost efficiency, and environmental sustainability considerations.

Quality Standards and Certifications

River sand is naturally sourced and often subject to environmental regulations, with quality standards such as ASTM C33 ensuring its grain size and cleanliness for construction use. M-sand, or manufactured sand, undergoes a controlled crushing and screening process, meeting certification benchmarks like IS 383 in India that guarantee consistent particle size and lower impurities. Both types of sand must comply with industry standards to ensure strength, durability, and safety in building materials.

Future Trends in Sand Usage for Construction

River sand extraction faces increasing environmental restrictions, driving the construction industry toward sustainable alternatives like M-sand, which is manufactured from crushed rock and has consistent grain size. Advances in processing technologies are improving the quality and availability of M-sand, making it a preferred choice for future infrastructure projects. The growing emphasis on eco-friendly construction practices and resource conservation is expected to accelerate the adoption of M-sand globally.

River sand vs M-sand Infographic

materialdif.com

materialdif.com