Hydraulic fracturing relies on sand's high silica content and angular shape to prop open fractures in underground rock formations, enhancing oil and gas extraction. In contrast, glassmaking utilizes sand's purity and uniform grain size to produce clear, durable glass materials through melting and refining processes. Both industries exploit sand's unique mineral properties but apply them in fundamentally different ways to meet specific functional requirements.

Table of Comparison

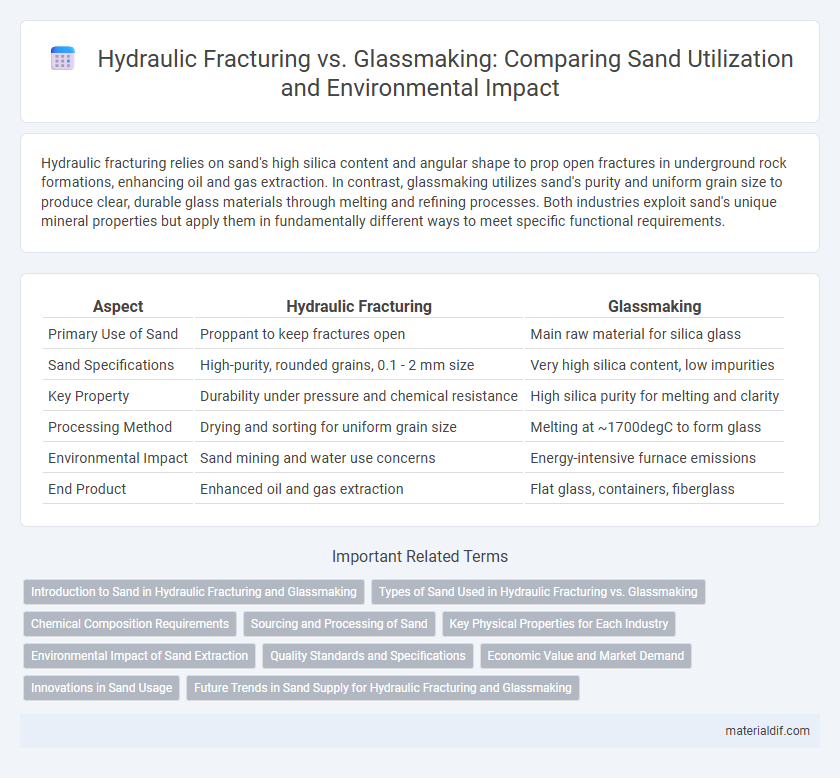

| Aspect | Hydraulic Fracturing | Glassmaking |

|---|---|---|

| Primary Use of Sand | Proppant to keep fractures open | Main raw material for silica glass |

| Sand Specifications | High-purity, rounded grains, 0.1 - 2 mm size | Very high silica content, low impurities |

| Key Property | Durability under pressure and chemical resistance | High silica purity for melting and clarity |

| Processing Method | Drying and sorting for uniform grain size | Melting at ~1700degC to form glass |

| Environmental Impact | Sand mining and water use concerns | Energy-intensive furnace emissions |

| End Product | Enhanced oil and gas extraction | Flat glass, containers, fiberglass |

Introduction to Sand in Hydraulic Fracturing and Glassmaking

Sand used in hydraulic fracturing, commonly known as frac sand, is a high-purity quartz with specific grain size and strength to withstand high pressure during the extraction of oil and gas. In contrast, glassmaking requires silica sand with high silica content and minimal impurities to ensure clarity and quality in the final glass products. Both industries depend heavily on the physical and chemical properties of sand, such as grain size distribution, durability, and silica concentration, to optimize their respective processes.

Types of Sand Used in Hydraulic Fracturing vs. Glassmaking

Hydraulic fracturing primarily uses high-purity quartz sand, known as frac sand, characterized by its round shape, uniform size, and high compressive strength to prop open fractures in shale formations. Glassmaking requires finer, more spherical silica sand with low iron content to ensure optical clarity and color consistency in glass products. The distinct granulometry and mineral purity requirements differentiate frac sand from glass sand, reflecting the specialized needs of each industry.

Chemical Composition Requirements

Hydraulic fracturing sand requires high-purity quartz with minimal iron oxide content, typically exceeding 99% silica (SiO2), to withstand high pressures and prevent contamination in oil and gas extraction. Glassmaking sand demands an even higher level of purity, often above 99.5% silica, with extremely low levels of impurities such as aluminum oxide, iron oxide, and calcium, ensuring clarity and color consistency in glass products. The chemical composition for hydraulic fracturing prioritizes mechanical strength and crushing resistance, while glassmaking focuses on optical properties and melting behavior influenced by the sand's elemental purity.

Sourcing and Processing of Sand

Hydraulic fracturing requires high-purity, angular silica sand sourced primarily from specialized mines in the Midwest United States, where processing involves rigorous washing, drying, and grading to meet stringent frac sand specifications. Glassmaking depends on finer, more uniform silica sand typically extracted from deposits with low iron content, undergoing refining processes such as magnetic separation and acid leaching to ensure clarity and quality. The distinct sourcing regions and tailored processing methods reflect the unique performance demands of sand in hydraulic fracturing and glass manufacturing industries.

Key Physical Properties for Each Industry

Hydraulic fracturing requires sand with high crush resistance and roundness to maintain permeability and withstand high pressure in subterranean formations. Glassmaking demands sand with high silica content, consistent grain size, and low impurities to ensure clarity and durability of glass products. The hardness and angularity of sand grains are crucial for hydraulic fracturing, whereas purity and uniformity dominate sand quality in glass manufacturing.

Environmental Impact of Sand Extraction

Hydraulic fracturing consumes vast quantities of sand, leading to significant disruption of natural landscapes, groundwater contamination, and increased air pollution due to dust from extraction sites. In contrast, sand used in glassmaking is often refined and sourced with stricter environmental regulations, resulting in comparatively lower ecological damage. The large-scale sand mining for hydraulic fracturing accelerates habitat destruction and poses higher risks to biodiversity than sand extraction for glass production.

Quality Standards and Specifications

Hydraulic fracturing sand requires strict quality standards such as high crush resistance, low fines content, and uniform grain size to ensure durability and effective proppant performance under extreme pressure conditions. Glassmaking sand mandates high silica content (typically over 95%) with minimal impurities like iron oxide to achieve clarity and consistency in glass production. Both industries adhere to precise specifications, but hydraulic fracturing prioritizes mechanical strength while glassmaking focuses on chemical purity.

Economic Value and Market Demand

Hydraulic fracturing drives the demand for high-quality silica sand, valued for its strength, roundness, and chemical composition to optimize oil and gas extraction, generating billions in economic activity globally. Glassmaking relies on silica sand with low iron content to ensure clarity and durability in products, sustaining a consistent market demand tied to construction and manufacturing sectors. The hydraulic fracturing sand market experiences greater price volatility and higher volume growth compared to the steady, specialty-grade sand requirements of the glass industry.

Innovations in Sand Usage

Innovations in sand usage highlight hydraulic fracturing's demand for high-purity, uniformly sized frac sand to enhance oil and gas extraction efficiency, while glassmaking advances rely on silica sand with exceptional clarity and chemical composition for superior product quality. Recent developments include engineered sand treatments that improve proppant strength in fracking and refined purification methods to reduce impurities in glass production. Both industries are innovating to optimize sand characteristics, thereby maximizing performance and sustainability in resource utilization.

Future Trends in Sand Supply for Hydraulic Fracturing and Glassmaking

The future trends in sand supply for hydraulic fracturing and glassmaking reveal increasing demand driven by technological advancements and expanding markets. Innovations in sourcing and processing high-purity silica sand aim to optimize resource efficiency while minimizing environmental impacts. Sustainable extraction practices and alternative materials are becoming critical to meeting the escalating requirements of both industries.

Hydraulic fracturing vs Glassmaking Infographic

materialdif.com

materialdif.com