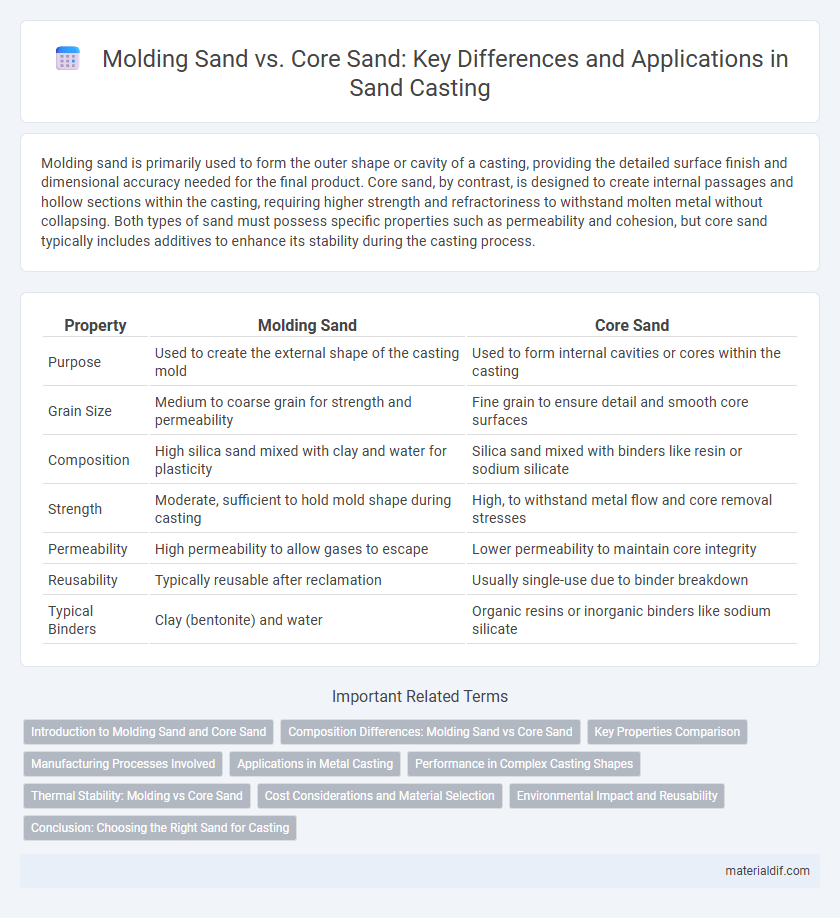

Molding sand is primarily used to form the outer shape or cavity of a casting, providing the detailed surface finish and dimensional accuracy needed for the final product. Core sand, by contrast, is designed to create internal passages and hollow sections within the casting, requiring higher strength and refractoriness to withstand molten metal without collapsing. Both types of sand must possess specific properties such as permeability and cohesion, but core sand typically includes additives to enhance its stability during the casting process.

Table of Comparison

| Property | Molding Sand | Core Sand |

|---|---|---|

| Purpose | Used to create the external shape of the casting mold | Used to form internal cavities or cores within the casting |

| Grain Size | Medium to coarse grain for strength and permeability | Fine grain to ensure detail and smooth core surfaces |

| Composition | High silica sand mixed with clay and water for plasticity | Silica sand mixed with binders like resin or sodium silicate |

| Strength | Moderate, sufficient to hold mold shape during casting | High, to withstand metal flow and core removal stresses |

| Permeability | High permeability to allow gases to escape | Lower permeability to maintain core integrity |

| Reusability | Typically reusable after reclamation | Usually single-use due to binder breakdown |

| Typical Binders | Clay (bentonite) and water | Organic resins or inorganic binders like sodium silicate |

Introduction to Molding Sand and Core Sand

Molding sand is a specially prepared type of sand used to create the outer shell of metal castings, characterized by its high clay content, moisture, and fine grain size to ensure shape retention and surface finish. Core sand, on the other hand, is specifically designed for forming internal cavities or hollow sections within castings, typically requiring better permeability, strength, and collapsibility to withstand metal flow and facilitate core removal. Both molding sand and core sand differ in composition and properties, optimized to meet their distinct functional roles in the casting process.

Composition Differences: Molding Sand vs Core Sand

Molding sand primarily consists of silica sand with clay as a binder, ensuring strength and plasticity for shaping molds, while core sand often contains higher silica content combined with binders like sodium silicate or resin to withstand higher temperatures and maintain core integrity. The grain size in molding sand is coarser for better permeability, whereas core sand has finer grains for precise core definition and surface finish. Organic additives are more common in core sand to enhance collapsibility and gas permeability during casting processes.

Key Properties Comparison

Molding sand, primarily used for creating the outer shape of a casting, features high clay content and exceptional cohesiveness to maintain mold integrity during metal pouring. Core sand, designed for forming internal cavities, exhibits superior refractoriness and collapsibility to withstand high temperatures and facilitate easy removal after solidification. Both sands differ significantly in permeability, strength, and grain size distribution, tailored specifically to their casting functions.

Manufacturing Processes Involved

Molding sand, primarily used in the casting process, is a mixture of sand, clay, and water that forms a mold to shape molten metal, requiring processes like sand preparation, mixing, and mold making. Core sand, specially treated with binders and additives, is used to create internal cavities in castings through core making techniques such as core mixing, core shooting, and curing. Both sands undergo precise thermal and mechanical conditioning to ensure dimensional accuracy and surface finish in metal casting manufacturing.

Applications in Metal Casting

Molding sand is primarily used to create the outer shape of a casting by forming the mold into which molten metal is poured, providing structural support and surface finish for the final product. Core sand is specialized to form internal cavities and complex hollow sections within the casting, ensuring precise internal geometries that molding sand cannot achieve. Both sands differ in composition and properties to optimize their performance in metal casting applications, with molding sand emphasizing strength and surface quality, while core sand focuses on collapsibility and high refractory characteristics.

Performance in Complex Casting Shapes

Molding sand offers high compressive strength and good cohesiveness, making it ideal for forming the outer shape of complex castings with precise surface detail. Core sand is specifically engineered for creating internal cavities, providing optimal permeability and collapsibility to maintain dimensional accuracy and prevent defects during metal flow. The combined use of molding and core sands enhances performance by ensuring structural integrity while accommodating intricate internal geometries in complex casting shapes.

Thermal Stability: Molding vs Core Sand

Molding sand typically exhibits lower thermal stability compared to core sand due to its composition and moisture content, which can lead to deformation or collapse under high temperatures during metal casting. Core sand is engineered with higher thermal resistance and bonding agents like sodium silicate or resins, allowing it to maintain shape and structural integrity in the extreme heat of molten metal. The enhanced thermal stability of core sand is critical for producing detailed internal cavities and complex geometries within castings.

Cost Considerations and Material Selection

Molding sand, typically composed of a higher clay content like bentonite, offers better cohesion and reusability but tends to be more expensive compared to core sand, which usually uses sand with lower clay content mixed with binders for strength and heat resistance. Cost considerations favor core sand for complex internal geometries due to its specialized binders, despite a potentially higher initial material price, as it reduces defects and post-processing expenses. Material selection depends on desired surface finish and thermal stability, with molding sand preferred for external casting surfaces and core sand optimized for internal passages where strength at elevated temperatures is critical.

Environmental Impact and Reusability

Molding sand, typically composed of silica sand, bentonite clay, and water, demonstrates higher reusability but generates more waste dust during the casting process, affecting air quality. Core sand often contains organic binders like resins, resulting in more challenging recycling and increased production of harmful gases upon firing, posing greater environmental concerns. Both sands require careful management, but molding sand exhibits comparatively lower environmental impact and enhanced potential for reuse in foundry operations.

Conclusion: Choosing the Right Sand for Casting

Selecting the appropriate sand for casting depends on the specific requirements of the mold and core. Molding sand, typically composed of silica with clay and water, offers excellent support for external shapes and surface finish. Core sand, formulated with higher refractory properties and binders, ensures dimensional accuracy and stability in internal cavities of casting.

Molding sand vs Core sand Infographic

materialdif.com

materialdif.com