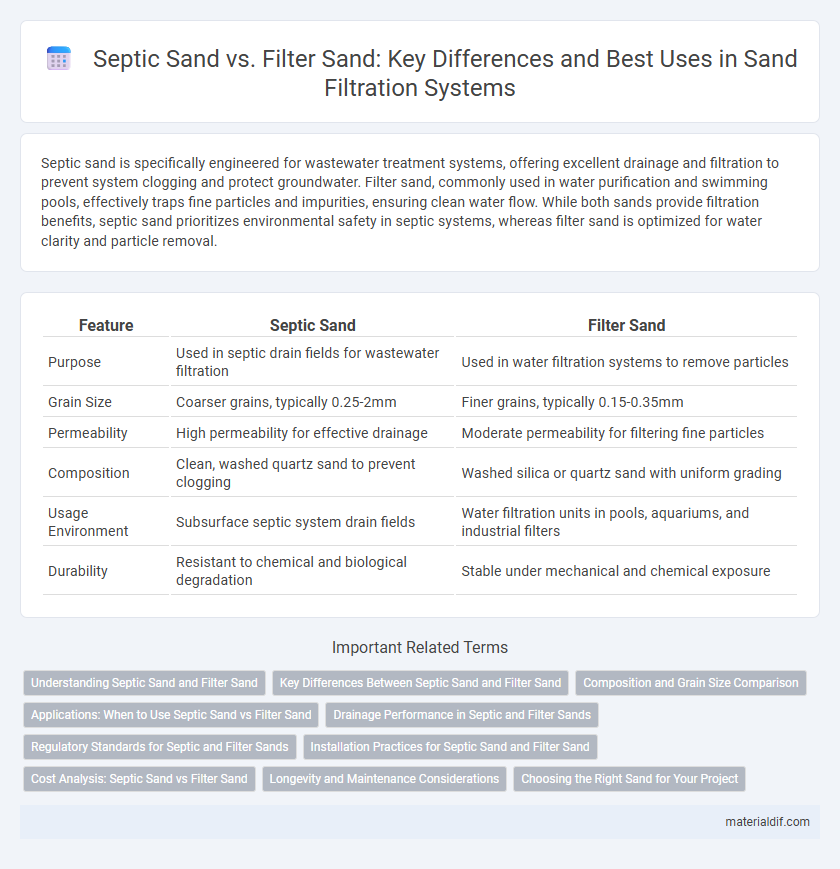

Septic sand is specifically engineered for wastewater treatment systems, offering excellent drainage and filtration to prevent system clogging and protect groundwater. Filter sand, commonly used in water purification and swimming pools, effectively traps fine particles and impurities, ensuring clean water flow. While both sands provide filtration benefits, septic sand prioritizes environmental safety in septic systems, whereas filter sand is optimized for water clarity and particle removal.

Table of Comparison

| Feature | Septic Sand | Filter Sand |

|---|---|---|

| Purpose | Used in septic drain fields for wastewater filtration | Used in water filtration systems to remove particles |

| Grain Size | Coarser grains, typically 0.25-2mm | Finer grains, typically 0.15-0.35mm |

| Permeability | High permeability for effective drainage | Moderate permeability for filtering fine particles |

| Composition | Clean, washed quartz sand to prevent clogging | Washed silica or quartz sand with uniform grading |

| Usage Environment | Subsurface septic system drain fields | Water filtration units in pools, aquariums, and industrial filters |

| Durability | Resistant to chemical and biological degradation | Stable under mechanical and chemical exposure |

Understanding Septic Sand and Filter Sand

Septic sand is specifically designed for use in wastewater treatment systems, facilitating efficient drainage and filtration while preventing clogging in septic drain fields. Filter sand, commonly used in water filtration systems, possesses uniform grain size and high permeability to remove suspended particles and impurities from water. Understanding the distinct properties of septic sand and filter sand ensures optimal performance in environmental and water purification applications.

Key Differences Between Septic Sand and Filter Sand

Septic sand is specifically designed for use in septic drain fields, featuring coarse granules that facilitate wastewater filtration and promote aerobic bacterial activity, whereas filter sand is engineered for water filtration processes with finer grains that trap smaller particles. The permeability rate of septic sand is higher to ensure proper drainage and prevent system clogging, while filter sand prioritizes particle retention to enhance water clarity. Understanding these differences is essential for selecting the appropriate sand type to optimize system efficiency and longevity in septic and filtration applications.

Composition and Grain Size Comparison

Septic sand typically consists of coarser grains ranging from 0.6 to 2.0 mm in diameter, enhancing drainage and preventing clogging in septic systems, while filter sand features finer grains generally between 0.1 and 0.5 mm to effectively capture particles during filtration. The composition of septic sand is predominantly quartz with minimal impurities to ensure durability and chemical resistance, whereas filter sand may include a mix of quartz and silica with varying purity levels tailored for specific filtration needs. Understanding these differences in grain size and composition is crucial for optimizing soil permeability and filtration efficiency in wastewater and water treatment applications.

Applications: When to Use Septic Sand vs Filter Sand

Septic sand is specifically designed for use in septic systems where it enhances wastewater treatment by promoting natural filtration and preventing clogging. Filter sand, on the other hand, is ideal for water purification processes in swimming pools, water filtration systems, and industrial applications due to its uniform grain size and high porosity. Choose septic sand for drainage fields and leach lines, whereas filter sand is preferable for systems requiring precise particle retention and fluid clarity.

Drainage Performance in Septic and Filter Sands

Septic sand is specifically engineered to enhance percolation rates, ensuring effective wastewater dispersion in septic drain fields, while filter sand is designed primarily for filtration, capturing sediments and contaminants in water treatment systems. Drainage performance in septic sand relies on its coarse texture and uniform grain size, promoting optimal oxygen flow and preventing clogging. Filter sand typically features a finer grain structure that prioritizes impurity removal but may reduce overall drainage speed compared to septic sand.

Regulatory Standards for Septic and Filter Sands

Septic sand and filter sand must comply with specific regulatory standards to ensure effective wastewater treatment and environmental protection. Septic sand typically adheres to criteria set by the Environmental Protection Agency (EPA) and local health departments, emphasizing grain size, permeability, and absence of contaminants to prevent system failure and groundwater contamination. Filter sand used in water purification processes must meet standards outlined by organizations such as NSF International, focusing on particle uniformity, chemical inertness, and cleanliness to maintain filtration efficiency and potable water quality.

Installation Practices for Septic Sand and Filter Sand

Septic sand installation requires precise grading and uniform compaction to facilitate optimal wastewater filtration and prevent system failures, typically involving a thick layer of uniformly graded sand to ensure effective percolation. Filter sand installation demands careful placement of clean, angular sand layers to maximize filtration efficiency and prevent clogging, often including a geotextile fabric to separate the sand from underlying soil. Both practices emphasize maintaining sand porosity and avoiding contamination during installation to ensure the longevity and functionality of septic and filtration systems.

Cost Analysis: Septic Sand vs Filter Sand

Septic sand generally costs less than filter sand, making it a more economical choice for septic system installations and wastewater treatment. Filter sand, designed with uniform grain size for precise filtration, often has a higher price due to its specialized processing and quality standards. Evaluating the cost-benefit ratio depends on the specific filtration efficiency needed, as filter sand may reduce maintenance expenses despite its higher initial cost.

Longevity and Maintenance Considerations

Septic sand is specifically designed for septic drain fields, featuring high permeability for efficient wastewater filtration, which extends system longevity with minimal clogging issues. Filter sand, commonly used in water filtration systems, requires regular backwashing and maintenance to prevent compaction and maintain flow rates, influencing its operational lifespan. Proper selection based on application and maintenance protocols ensures optimal performance and durability for both sand types.

Choosing the Right Sand for Your Project

Septic sand is specifically graded for use in septic drain fields, featuring uniform particle size that enhances percolation and prevents clogging. Filter sand, commonly used in water treatment and filtration systems, has a finer texture to trap impurities while allowing water flow. Selecting the right sand depends on your project's drainage requirements and filtration efficiency, ensuring optimal performance and longevity.

Septic sand vs Filter sand Infographic

materialdif.com

materialdif.com