Resin-coated sand offers superior binding strength and reduces the amount of dust compared to ordinary sand, enhancing casting precision and surface finish in foundry applications. This type of sand improves mold stability and minimizes defects such as sand blow and veining, resulting in higher-quality metal castings. Unlike ordinary sand, resin-coated sand provides better friability and reusability, making it a cost-effective and environmentally friendly choice for industrial processes.

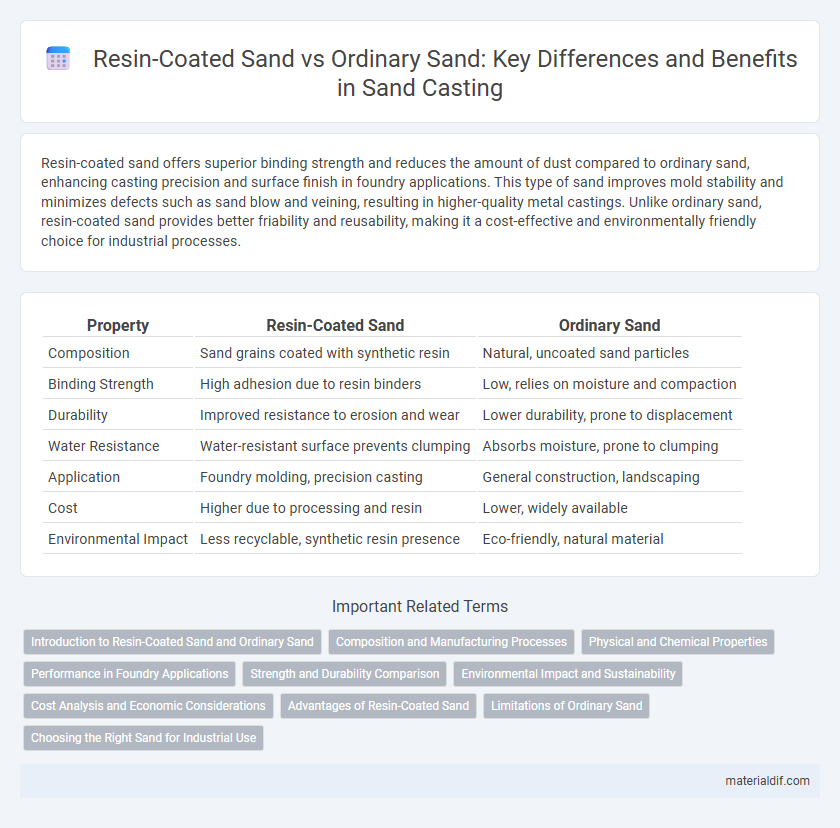

Table of Comparison

| Property | Resin-Coated Sand | Ordinary Sand |

|---|---|---|

| Composition | Sand grains coated with synthetic resin | Natural, uncoated sand particles |

| Binding Strength | High adhesion due to resin binders | Low, relies on moisture and compaction |

| Durability | Improved resistance to erosion and wear | Lower durability, prone to displacement |

| Water Resistance | Water-resistant surface prevents clumping | Absorbs moisture, prone to clumping |

| Application | Foundry molding, precision casting | General construction, landscaping |

| Cost | Higher due to processing and resin | Lower, widely available |

| Environmental Impact | Less recyclable, synthetic resin presence | Eco-friendly, natural material |

Introduction to Resin-Coated Sand and Ordinary Sand

Resin-coated sand consists of fine sand grains bonded with a thermosetting resin, enhancing strength and surface finish in casting processes compared to ordinary sand, which is natural or silica sand used without any binding agent. The resin coating provides improved mold stability, higher refractoriness, and reduced permeability, making it ideal for precision casting applications. Ordinary sand remains widely used due to its availability and cost-effectiveness but often requires additional binders or additives to achieve similar mold integrity.

Composition and Manufacturing Processes

Resin-coated sand consists of high-quality silica sand particles bonded with a thermosetting resin, enhancing strength and reducing dust, whereas ordinary sand is composed mainly of natural silica without any binding agent. The manufacturing process of resin-coated sand involves mixing clean sand with a resin binder followed by curing at controlled temperatures to achieve optimal hardness and durability. Ordinary sand is typically mined and screened with minimal processing, resulting in a looser texture and lower structural integrity compared to resin-coated sand.

Physical and Chemical Properties

Resin-coated sand exhibits enhanced physical properties such as improved strength, better flowability, and reduced dust compared to ordinary sand, making it ideal for molding applications. Chemically, resin-coated sand contains a thermosetting resin binder that provides durability and heat resistance, whereas ordinary sand lacks this resin, leading to lower bonding strength and higher susceptibility to moisture. The resin coating also minimizes chemical reactions with molten metals, enhancing the quality and surface finish of castings.

Performance in Foundry Applications

Resin-coated sand exhibits superior mold strength and surface finish compared to ordinary sand, enhancing pattern accuracy and dimensional stability in foundry applications. Its improved permeability facilitates better gas escape during casting, reducing defects such as porosity and blowholes. The enhanced recyclability and dust suppression of resin-coated sand contribute to a cleaner working environment and consistent casting quality.

Strength and Durability Comparison

Resin-coated sand exhibits superior strength and durability compared to ordinary sand due to the polymer resin binding agents that enhance particle cohesion and resistance to abrasion. This type of sand maintains structural integrity under high mechanical stress and reduces dust generation, making it ideal for foundry and casting applications. Ordinary sand, lacking these resin properties, tends to break down more easily and has lower resilience in demanding environments.

Environmental Impact and Sustainability

Resin-coated sand significantly reduces dust emissions and minimizes water contamination compared to ordinary sand, making it a more environmentally friendly option in foundry applications. Its recyclability enhances sustainability by lowering the demand for virgin sand extraction and decreasing landfill waste. The use of resin-coated sand also reduces the energy consumption associated with sand reclamation processes, contributing to a smaller carbon footprint.

Cost Analysis and Economic Considerations

Resin-coated sand typically incurs higher initial costs compared to ordinary sand due to the added resin material and processing expenses. Despite the upfront investment, resin-coated sand offers improved mold strength and reduced defects, leading to lower overall production costs and enhanced economic efficiency in foundry operations. Economically, the choice depends on weighing immediate material expenses against long-term savings from increased product quality and reduced rework.

Advantages of Resin-Coated Sand

Resin-coated sand offers superior strength and durability compared to ordinary sand, enhancing mold stability in foundry applications. Its improved surface bonding reduces defects and improves casting precision, resulting in higher-quality metal parts. The reusable nature of resin-coated sand also lowers waste and operational costs, making it an economical choice for industrial processes.

Limitations of Ordinary Sand

Ordinary sand often suffers from inconsistent grain size and higher moisture content, leading to weaker bonding and reduced mold strength in casting processes. Its irregular surface texture can cause poor permeability, increasing the risk of defects such as gas porosity in metal castings. Resin-coated sand offers enhanced cohesion and improved thermal stability, addressing these limitations by providing better mold integrity and surface finish quality.

Choosing the Right Sand for Industrial Use

Resin-coated sand offers superior strength, durability, and dust control compared to ordinary sand, making it ideal for high-precision industrial applications such as foundry molding and casting. Ordinary sand, while cost-effective and widely available, lacks binding properties and may result in lower-quality molds and increased defects. Selecting the right sand involves evaluating factors like grain size, resin compatibility, and project requirements to ensure optimal performance and efficiency in industrial processes.

Resin-Coated Sand vs Ordinary Sand Infographic

materialdif.com

materialdif.com