Kiln-dried sand undergoes a heating process to remove all moisture, resulting in a consistent, dry texture ideal for precise construction and masonry work. Moist sand contains natural water content, which can affect the strength and stability of concrete mixes by altering the water-cement ratio. Choosing kiln-dried sand ensures improved bonding, reduced shrinkage, and enhanced durability in finished structures.

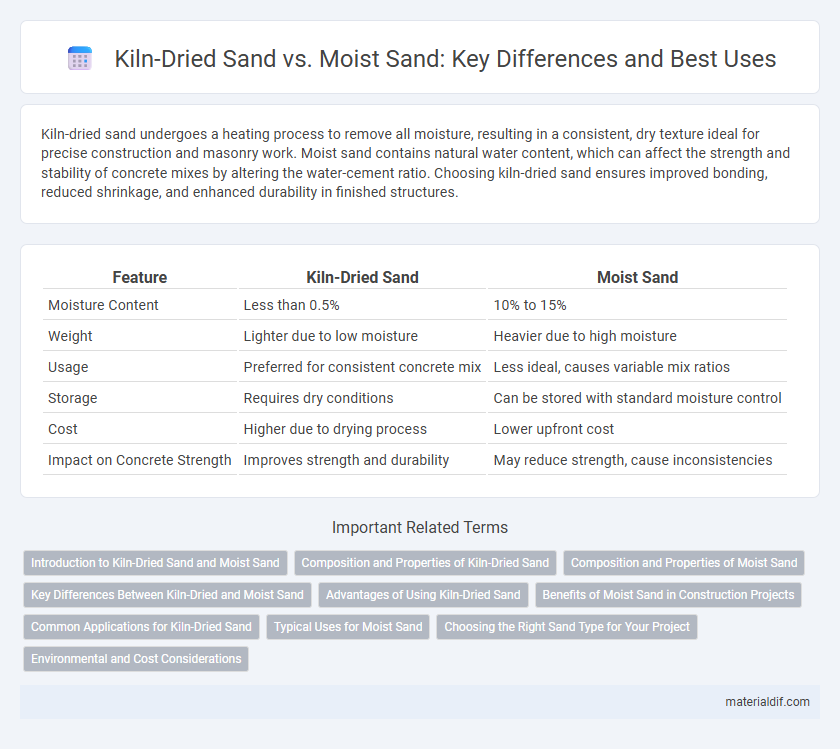

Table of Comparison

| Feature | Kiln-Dried Sand | Moist Sand |

|---|---|---|

| Moisture Content | Less than 0.5% | 10% to 15% |

| Weight | Lighter due to low moisture | Heavier due to high moisture |

| Usage | Preferred for consistent concrete mix | Less ideal, causes variable mix ratios |

| Storage | Requires dry conditions | Can be stored with standard moisture control |

| Cost | Higher due to drying process | Lower upfront cost |

| Impact on Concrete Strength | Improves strength and durability | May reduce strength, cause inconsistencies |

Introduction to Kiln-Dried Sand and Moist Sand

Kiln-dried sand is sand that has been heated in a kiln to remove moisture, resulting in a dry, free-flowing material ideal for precise mixing in construction and masonry. Moist sand retains natural water content, providing better compaction and workability but can cause variations in mix ratios and strength. Understanding the moisture content difference between kiln-dried and moist sand is essential for optimizing concrete and mortar performance.

Composition and Properties of Kiln-Dried Sand

Kiln-dried sand consists of fine, uniformly sized particles with a reduced moisture content below 1%, achieved through heating in a kiln, which enhances its drying and bonding properties in concrete and mortar mixes. Its low moisture level minimizes water absorption, leading to consistent mix proportions and improved strength in construction applications. The controlled particle size distribution and dryness ensure better workability and reduced shrinkage compared to moist sand, making kiln-dried sand ideal for precise masonry and plastering tasks.

Composition and Properties of Moist Sand

Moist sand contains a specific percentage of water, typically between 5% to 8%, which enhances its cohesiveness and compaction properties compared to kiln-dried sand that is nearly free of moisture. The presence of moisture in moist sand improves particle adhesion, making it ideal for construction applications like mortar and concrete where binding strength is essential. Its composition includes fine sand grains combined with moisture content that influences workability, density, and reduced dust generation during handling.

Key Differences Between Kiln-Dried and Moist Sand

Kiln-dried sand contains less than 1% moisture, making it ideal for mixing with cement in plastering and rendering, as it ensures better adhesion and faster setting times. Moist sand typically holds up to 5-10% moisture, which can lead to weaker mixes and longer drying periods due to excess water content. The consistent low moisture level in kiln-dried sand enhances workability and reduces the risk of shrinkage cracks in finished surfaces compared to moist sand.

Advantages of Using Kiln-Dried Sand

Kiln-dried sand offers superior moisture control, ensuring consistent mixing and improved bonding in construction and plastering applications. Its low moisture content prevents clumping and reduces the risk of mold growth, enhancing workability and durability. Using kiln-dried sand results in smoother finishes and faster drying times compared to moist sand.

Benefits of Moist Sand in Construction Projects

Moist sand enhances compaction and stability in construction projects by providing optimal moisture content that aids in binding particles, reducing voids and improving load-bearing capacity. Its superior workability compared to kiln-dried sand minimizes dust generation and facilitates easier handling, leading to faster and more efficient masonry and concrete mixing. The consistent moisture level in moist sand also reduces shrinkage and cracking risks in cured materials, ensuring long-term durability.

Common Applications for Kiln-Dried Sand

Kiln-dried sand is commonly used in construction for mixing with cement to create smooth, consistent mortar and concrete due to its low moisture content, which ensures accurate water-to-sand ratios. It is also preferred in plastering and rendering applications to achieve uniform finishes and reduce shrinkage cracks. Additionally, kiln-dried sand is ideal for manufacturing blocks and pavers where precise control over the mix quality is critical.

Typical Uses for Moist Sand

Moist sand is commonly used in construction for concrete mixing, as its natural moisture helps achieve the right consistency and workability without adding extra water. It is also ideal for laying bricks and blocks, where slight dampness improves adhesion and bond strength. Landscapers often choose moist sand for sandboxes and playgrounds to ensure compaction and reduce dust formation.

Choosing the Right Sand Type for Your Project

Kiln-dried sand offers consistent moisture content below 1%, ideal for indoor applications like rendering and plastering where precision and strength matter. Moist sand contains higher water content, which can affect the mix ratio and drying times, making it less suitable for projects requiring exact consistency. Selecting kiln-dried sand ensures improved adhesion, reduced shrinkage, and better overall durability in construction or finishing tasks.

Environmental and Cost Considerations

Kiln-dried sand offers lower moisture content, reducing transportation weight and drying energy costs compared to moist sand, which contains higher water percentages leading to increased fuel consumption during drying processes. Environmentally, kiln-dried sand contributes to reduced carbon emissions due to decreased energy use and less risk of microbial growth that can impact surrounding ecosystems. Cost-wise, initial investment in kiln-drying equipment is offset by long-term savings from improved sand quality and lower waste disposal expenses.

Kiln-Dried Sand vs Moist Sand Infographic

materialdif.com

materialdif.com