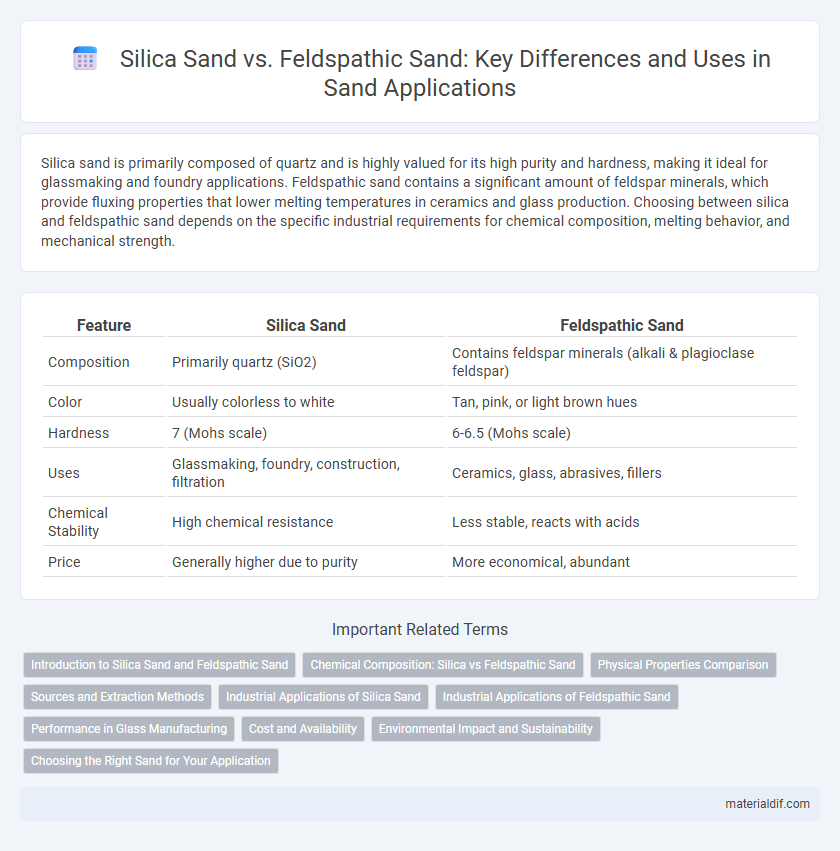

Silica sand is primarily composed of quartz and is highly valued for its high purity and hardness, making it ideal for glassmaking and foundry applications. Feldspathic sand contains a significant amount of feldspar minerals, which provide fluxing properties that lower melting temperatures in ceramics and glass production. Choosing between silica and feldspathic sand depends on the specific industrial requirements for chemical composition, melting behavior, and mechanical strength.

Table of Comparison

| Feature | Silica Sand | Feldspathic Sand |

|---|---|---|

| Composition | Primarily quartz (SiO2) | Contains feldspar minerals (alkali & plagioclase feldspar) |

| Color | Usually colorless to white | Tan, pink, or light brown hues |

| Hardness | 7 (Mohs scale) | 6-6.5 (Mohs scale) |

| Uses | Glassmaking, foundry, construction, filtration | Ceramics, glass, abrasives, fillers |

| Chemical Stability | High chemical resistance | Less stable, reacts with acids |

| Price | Generally higher due to purity | More economical, abundant |

Introduction to Silica Sand and Feldspathic Sand

Silica sand, primarily composed of quartz, is valued for its high purity and durability, making it essential in glassmaking, foundry casting, and hydraulic fracturing. Feldspathic sand contains a significant amount of feldspar minerals, contributing to its use in ceramics and as a flux in glass production due to its alumina and alkali content. Both sands differ in mineral composition and industrial applications, influencing their performance in construction and manufacturing processes.

Chemical Composition: Silica vs Feldspathic Sand

Silica sand primarily consists of silicon dioxide (SiO2), offering high purity and chemical stability that makes it ideal for glassmaking and foundry molds. Feldspathic sand contains significant amounts of feldspar minerals, including potassium, sodium, and calcium aluminosilicates, which impart different melting points and chemical reactivity. The chemical composition difference affects their thermal properties and suitability for various industrial applications such as ceramics and construction.

Physical Properties Comparison

Silica sand is characterized by a high quartz content, making it denser and harder with a Mohs hardness of 7 compared to feldspathic sand, which contains more feldspar minerals and has a lower hardness around 6.5. Silica sand typically exhibits higher specific gravity (2.65) and greater angularity, enhancing its strength and durability in industrial applications, whereas feldspathic sand has a slightly lower specific gravity (2.56) and more rounded grains, reducing its abrasion resistance. The thermal stability of silica sand surpasses feldspathic sand, with silica maintaining integrity up to 1710degC, while feldspathic sand begins to deform at lower temperatures due to feldspar components.

Sources and Extraction Methods

Silica sand primarily originates from quartz-rich rocks such as granite and sandstone, extracted through open-pit mining and river dredging, enabling high-purity quartz collection essential for industrial applications. Feldspathic sand, sourced mainly from feldspar-bearing granite and pegmatite formations, is typically mined via conventional quarrying and blasting methods to ensure adequate feldspar content for ceramics and glass manufacturing. Extraction efficiency depends on geological conditions, with silica sand favoring sedimentary environments and feldspathic sand often requiring more intensive processing due to mineral impurities.

Industrial Applications of Silica Sand

Silica sand, primarily composed of silicon dioxide, is essential in industrial applications such as glass manufacturing, foundry molds, and hydraulic fracturing due to its high purity and consistent grain size. Feldspathic sand contains feldspar minerals, which can alter chemical compositions and reduce suitability for precision processes compared to silica sand. The superior thermal resistance and chemical inertness of silica sand make it the preferred choice for producing high-quality glass and casting molds in metal foundries.

Industrial Applications of Feldspathic Sand

Feldspathic sand is extensively used in the glass manufacturing industry due to its high alumina content, which enhances the durability and chemical resistance of glass products. Its unique composition makes it valuable in ceramics and foundry applications, improving the strength and thermal stability of molds and ceramic materials. The presence of feldspar minerals in feldspathic sand also contributes to the fluxing properties essential for producing specialized glass and ceramic products.

Performance in Glass Manufacturing

Silica sand, composed primarily of quartz, offers superior purity and high melting points essential for producing clear, strong glass with minimal impurities. Feldspathic sand contains significant feldspar content, introducing alumina and alkalis that reduce melting temperature but can cause defects in glass clarity and durability. Silica sand's consistent chemical composition ensures optimal performance for high-quality glass manufacturing, whereas feldspathic sand suits applications requiring lower energy consumption but compromises on glass strength.

Cost and Availability

Silica sand generally costs more due to its high purity and widespread demand in industries like glassmaking and construction, whereas feldspathic sand is often less expensive because it contains feldspar minerals that reduce its overall purity. Availability of silica sand varies regionally but is generally abundant in areas with sandstone deposits, while feldspathic sand is more common in regions with granite and metamorphic rock formations. Cost-effectiveness depends on the intended application, with feldspathic sand preferred for ceramics and glass manufacturing when budget constraints are critical.

Environmental Impact and Sustainability

Silica sand mining often causes significant environmental disruption due to high energy extraction processes and dust emissions, impacting air quality and local ecosystems. Feldspathic sand extraction generally has a lower environmental footprint as it requires less energy and produces fewer airborne particulates, making it a more sustainable option in construction and glass manufacturing. Sustainable practices include implementing responsible mining regulations, restoring habitats post-extraction, and promoting recycled materials to mitigate long-term ecological damage.

Choosing the Right Sand for Your Application

Silica sand offers high purity and consistent grain size, making it ideal for glassmaking, foundry molds, and water filtration systems. Feldspathic sand contains feldspar minerals that provide beneficial fluxing properties, enhancing ceramic and porcelain manufacturing processes. Choose silica sand for applications requiring high hardness and chemical stability, while feldspathic sand suits high-temperature processes needing improved melting characteristics.

Silica Sand vs Feldspathic Sand Infographic

materialdif.com

materialdif.com