Resin-coated sand offers enhanced durability and improved mold stability compared to raw sand, making it ideal for precision casting applications. The resin coating binds sand particles, reducing dust and increasing resistance to abrasion and moisture. Raw sand remains more cost-effective but lacks the consistent strength and surface finish quality provided by resin-coated sand in industrial processes.

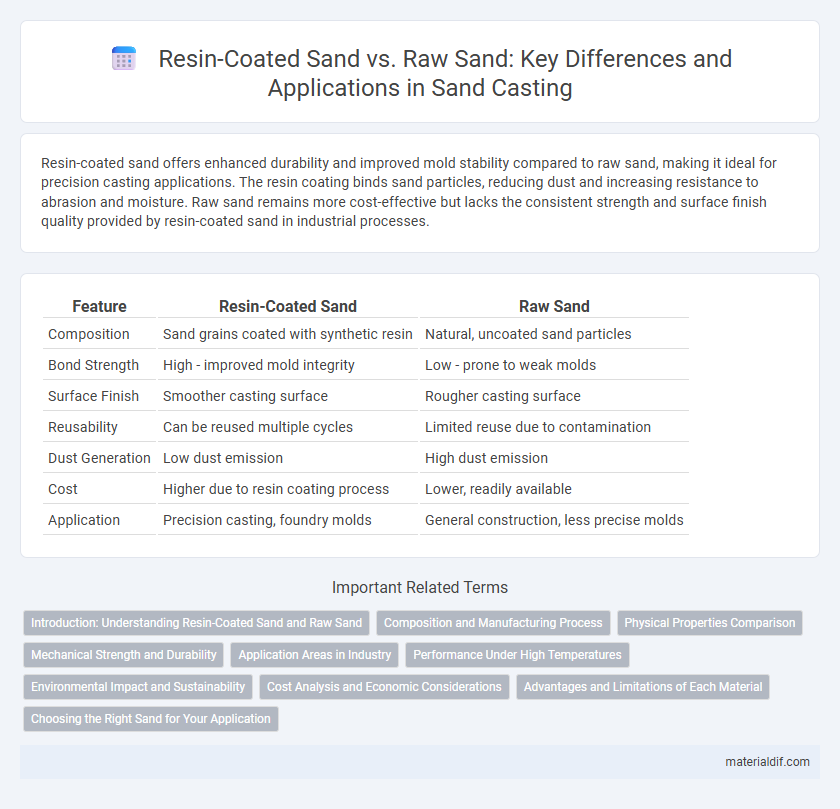

Table of Comparison

| Feature | Resin-Coated Sand | Raw Sand |

|---|---|---|

| Composition | Sand grains coated with synthetic resin | Natural, uncoated sand particles |

| Bond Strength | High - improved mold integrity | Low - prone to weak molds |

| Surface Finish | Smoother casting surface | Rougher casting surface |

| Reusability | Can be reused multiple cycles | Limited reuse due to contamination |

| Dust Generation | Low dust emission | High dust emission |

| Cost | Higher due to resin coating process | Lower, readily available |

| Application | Precision casting, foundry molds | General construction, less precise molds |

Introduction: Understanding Resin-Coated Sand and Raw Sand

Resin-coated sand features a durable outer layer of resin binder that significantly enhances its strength and binding properties compared to raw sand, which consists solely of loose granules without any coating. This specialized coating improves moldability, reduces permeability, and increases resistance to erosion, making resin-coated sand ideal for precision casting applications. In contrast, raw sand is primarily used where cost efficiency is critical, but it lacks the enhanced performance characteristics vital for complex or high-strength foundry processes.

Composition and Manufacturing Process

Resin-coated sand is composed of high-quality silica sand grains bonded with a thermosetting resin, enhancing strength and moldability, whereas raw sand consists primarily of unprocessed silica with natural impurities. The manufacturing process of resin-coated sand involves mixing raw sand with resin binders followed by controlled curing to create a durable, uniform coating, while raw sand is simply extracted, screened, and washed without additional treatment. These differences in composition and manufacturing result in resin-coated sand exhibiting superior resistance to deformation and better surface finish in foundry applications compared to raw sand.

Physical Properties Comparison

Resin-coated sand exhibits superior physical properties compared to raw sand, including enhanced grain strength and improved surface smoothness due to the polymer coating. This coating significantly increases the sand's resistance to erosion and abrasion, making it ideal for high-precision applications like metal casting. Raw sand, although naturally abundant and cost-effective, lacks the binding strength and uniformity provided by resin coatings, resulting in higher dust content and weaker molding characteristics.

Mechanical Strength and Durability

Resin-coated sand exhibits significantly higher mechanical strength compared to raw sand, as the resin binds the grains firmly, reducing friability and enhancing mold stability. The coating improves durability by providing resistance to moisture and thermal degradation, which prevents breakdown during casting processes. Raw sand lacks these protective properties, resulting in lower strength and weakened durability under high-stress conditions.

Application Areas in Industry

Resin-coated sand is extensively used in the foundry industry for metal casting due to its superior mold strength and surface finish, enhancing precision in automotive and aerospace component manufacturing. Raw sand primarily serves in construction and glass production, where its natural composition supports structural integrity and transparency requirements. Industries prioritize resin-coated sand when detailed shaping and high-temperature resistance are critical, whereas raw sand remains essential for large-scale infrastructural applications.

Performance Under High Temperatures

Resin-coated sand exhibits superior thermal stability compared to raw sand, maintaining structural integrity and reducing deformation under high-temperature conditions. The resin binder enhances heat resistance, preventing breakdown and ensuring consistent mold strength during casting. Raw sand lacks this thermal resilience, often resulting in decreased performance and potential defects when exposed to elevated temperatures.

Environmental Impact and Sustainability

Resin-coated sand offers improved recyclability and reduced waste compared to raw sand used in foundries, leading to lower environmental impact during metal casting processes. The binding resin enables multiple reuse cycles, minimizing sand consumption and landfill disposal, which supports sustainable manufacturing practices. Raw sand extraction depletes natural resources and generates more dust and pollution, making resin-coated alternatives a greener choice for sustainable production.

Cost Analysis and Economic Considerations

Resin-coated sand typically incurs higher initial costs compared to raw sand due to the additional manufacturing processes and materials required for resin application. Despite the upfront investment, resin-coated sand can lead to long-term economic benefits by improving mold strength and reducing defects, which minimizes wasted materials and rework expenses. Raw sand offers lower direct costs but may result in higher overall operational costs due to increased risks of mold failure and lower casting quality.

Advantages and Limitations of Each Material

Resin-coated sand offers improved mold strength and durability, enhancing surface finish quality and reducing bending and erosion during casting, while raw sand is more cost-effective and widely available but tends to produce rougher surfaces and lower strength molds prone to collapse. The chemical bonding in resin-coated sand facilitates better control of permeability and dimensional accuracy, whereas raw sand's natural grain structure limits precision and increases the risk of defects in complex castings. However, resin-coated sand requires careful handling due to potential environmental concerns from resin emissions, whereas raw sand is environmentally benign but demands more frequent mold repair and maintenance.

Choosing the Right Sand for Your Application

Resin-coated sand offers enhanced strength, improved surface finish, and reduced defects in foundry molds compared to raw sand, making it ideal for high-precision casting applications. Raw sand is more cost-effective and suitable for general mold-making where surface quality is less critical and complex geometries are minimal. Selecting the right sand depends on factors such as casting requirements, budget constraints, and desired surface detail to optimize production efficiency and product quality.

Resin-coated sand vs Raw sand Infographic

materialdif.com

materialdif.com