Coloured sand offers vibrant hues that enhance decorative projects, providing a visually appealing alternative to the uniform appearance of white silica sand. White silica sand is prized for its purity and consistency, making it ideal for filtration, construction, and industrial applications. Choosing between coloured and white silica sand depends on the specific aesthetic or functional requirements of your project.

Table of Comparison

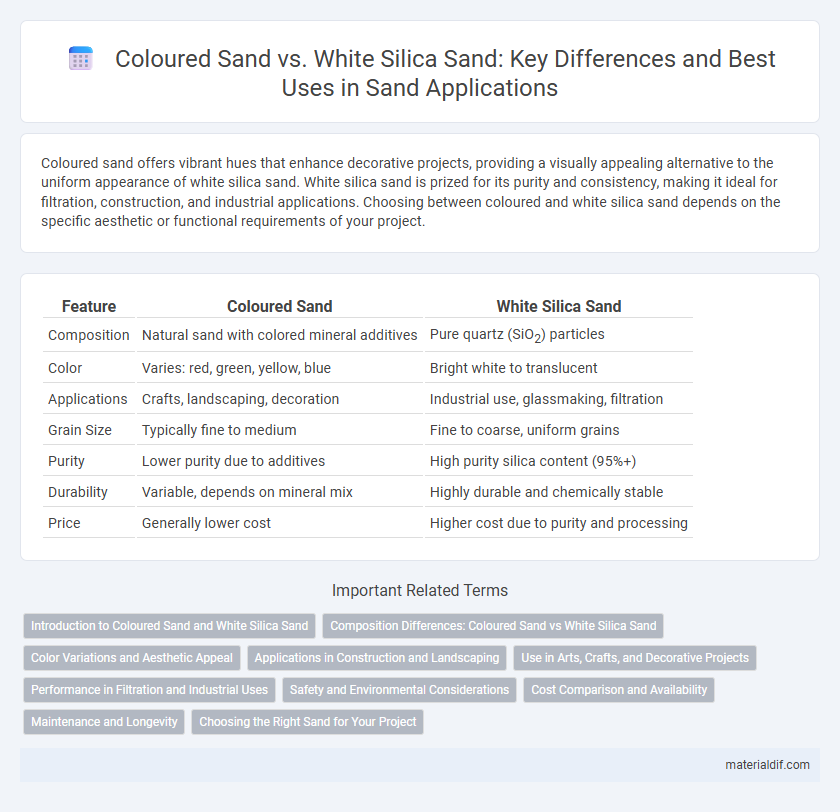

| Feature | Coloured Sand | White Silica Sand |

|---|---|---|

| Composition | Natural sand with colored mineral additives | Pure quartz (SiO2) particles |

| Color | Varies: red, green, yellow, blue | Bright white to translucent |

| Applications | Crafts, landscaping, decoration | Industrial use, glassmaking, filtration |

| Grain Size | Typically fine to medium | Fine to coarse, uniform grains |

| Purity | Lower purity due to additives | High purity silica content (95%+) |

| Durability | Variable, depends on mineral mix | Highly durable and chemically stable |

| Price | Generally lower cost | Higher cost due to purity and processing |

Introduction to Coloured Sand and White Silica Sand

Coloured sand is composed of natural or manufactured pigments mixed with silica or quartz particles, offering a vibrant range of hues ideal for decorative and artistic applications. White silica sand, primarily made of quartz with high purity levels over 95%, is valued for its consistent grain size, chemical inertness, and superior clarity in industrial uses such as glassmaking and construction. The key differences lie in their composition, color variety, and specific uses, with coloured sand emphasizing aesthetics and white silica sand focusing on functional performance.

Composition Differences: Coloured Sand vs White Silica Sand

Coloured sand contains a variety of mineral impurities such as iron oxide, garnet, and other trace elements that give it distinctive hues, whereas white silica sand is primarily composed of pure quartz (silicon dioxide) with minimal impurities. The high purity of white silica sand results in its bright white appearance and makes it ideal for industrial applications like glassmaking and foundry molds. In contrast, the mineral diversity in coloured sand influences both its color and physical properties, often limiting its use to decorative or landscaping purposes.

Color Variations and Aesthetic Appeal

Coloured sand offers a diverse palette ranging from vibrant reds and yellows to deep blues and greens, making it a popular choice for decorative and artistic applications where visual impact is essential. White silica sand, known for its purity and fine grain, provides a clean, bright backdrop ideal for landscaping and aquarium substrates, enhancing light reflection and contrast. The aesthetic appeal of coloured sand lies in its ability to create dynamic, eye-catching patterns, while white silica sand emphasizes simplicity and natural elegance.

Applications in Construction and Landscaping

Coloured sand offers unique aesthetic appeal in landscaping projects, ideal for decorative pathways, garden beds, and playgrounds, while white silica sand is prized in construction for its high purity and strength, essential in concrete production, mortar, and as a base material. The vibrant hues of coloured sand enhance visual design without compromising drainage, whereas white silica sand provides superior durability and chemical resistance in structural applications. Choosing between coloured sand and white silica sand depends on whether the priority is decorative enhancement or foundational strength in construction and landscaping environments.

Use in Arts, Crafts, and Decorative Projects

Coloured sand offers vibrant hues that enhance creativity in arts, crafts, and decorative projects, allowing for detailed designs and layered textures. White silica sand provides a neutral, smooth base ideal for mixing with pigments or creating elegant, minimalist aesthetics. Both sands differ significantly in composition and color stability, impacting their suitability for specific artistic applications.

Performance in Filtration and Industrial Uses

Coloured sand often contains impurities and varies in mineral composition, which can reduce its filtration efficiency compared to the high purity and uniform grain size of white silica sand, making silica sand the preferred choice for industrial filtration systems. White silica sand exhibits superior mechanical strength and chemical stability, enhancing its performance in water treatment, glass manufacturing, and foundry applications. Industrial processes requiring precision filtration and durability favor white silica sand due to its consistent particle size distribution and minimal contamination.

Safety and Environmental Considerations

Coloured sand often contains synthetic dyes and additives that may release harmful chemicals when exposed to moisture or heat, posing safety risks during handling and disposal. White silica sand, primarily composed of inert quartz, presents fewer toxic hazards but requires caution due to respirable crystalline silica dust, which can cause respiratory issues such as silicosis. Environmentally, coloured sand's additives may contribute to soil and water contamination, whereas white silica sand is more environmentally stable but demands controlled dust management to minimize airborne particulate pollution.

Cost Comparison and Availability

Coloured sand typically costs more than white silica sand due to the additional processing and pigments required to achieve vibrant hues. White silica sand is widely available and often sourced in bulk, making it more economical for large-scale industrial use. Availability of coloured sand is more limited and region-specific, impacting its price and accessibility in various markets.

Maintenance and Longevity

Coloured sand requires more frequent maintenance than white silica sand due to its susceptibility to fading and color degradation from exposure to sunlight and moisture. White silica sand offers superior longevity as it maintains its appearance and structural integrity with minimal upkeep, making it ideal for long-term applications. Proper sealing and periodic cleaning can extend the lifespan of coloured sand but generally do not match the durability of pure white silica sand.

Choosing the Right Sand for Your Project

Coloured sand offers vibrant aesthetics ideal for decorative projects, landscaping, and creative art, while white silica sand provides high purity and consistent grain size essential for industrial applications such as glassmaking and construction. Selecting the right sand depends on the project's functional requirements--coloured sand enhances visual appeal, whereas white silica sand ensures structural integrity and performance. Consider factors like grain size, mineral composition, and end use to optimize material choice for durability and design effectiveness.

Coloured sand vs White silica sand Infographic

materialdif.com

materialdif.com