Polishing sand consists of fine, smooth granules ideal for gently refining surfaces and creating a high-gloss finish without causing damage. Blasting sand features coarser, more abrasive particles designed to remove rust, paint, and contaminants from surfaces through high-pressure impact. Choosing between polishing sand and blasting sand depends on the desired surface treatment, where precision and delicacy require polishing sand, and aggressive cleaning demands blasting sand.

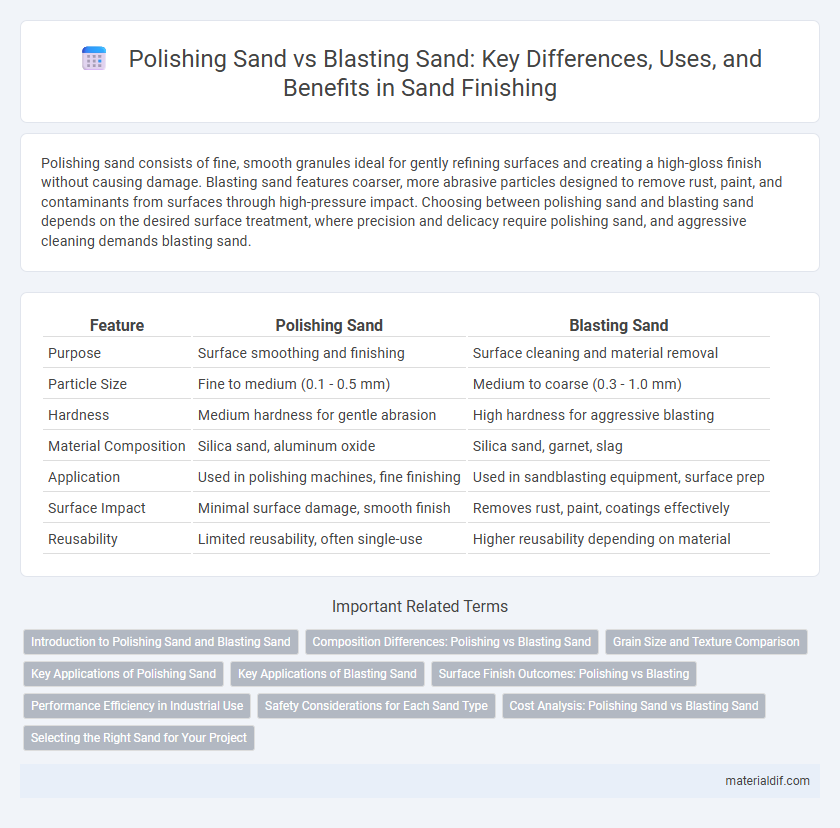

Table of Comparison

| Feature | Polishing Sand | Blasting Sand |

|---|---|---|

| Purpose | Surface smoothing and finishing | Surface cleaning and material removal |

| Particle Size | Fine to medium (0.1 - 0.5 mm) | Medium to coarse (0.3 - 1.0 mm) |

| Hardness | Medium hardness for gentle abrasion | High hardness for aggressive blasting |

| Material Composition | Silica sand, aluminum oxide | Silica sand, garnet, slag |

| Application | Used in polishing machines, fine finishing | Used in sandblasting equipment, surface prep |

| Surface Impact | Minimal surface damage, smooth finish | Removes rust, paint, coatings effectively |

| Reusability | Limited reusability, often single-use | Higher reusability depending on material |

Introduction to Polishing Sand and Blasting Sand

Polishing sand offers fine, smooth grains ideal for surface finishing and delicate material enhancement, delivering a refined texture without causing significant abrasion. Blasting sand consists of coarser, more abrasive particles designed to rapidly remove paint, rust, or contaminants from surfaces, making it effective for industrial cleaning and preparation. Understanding the distinct grain size and abrasiveness of each type is crucial for selecting the right sand for specific applications such as surface treatment or material refinement.

Composition Differences: Polishing vs Blasting Sand

Polishing sand primarily consists of fine, uniform silica grains that create a smooth surface finish by gently abrading materials without causing deep scratches. Blasting sand contains coarser, angular grains often mixed with minerals like garnet or aluminum oxide to provide aggressive abrasion for surface cleaning or preparation. The composition differences determine their suitability: polishing sand offers controlled abrasion for delicate surfaces, while blasting sand delivers high-impact erosion for tough industrial cleaning.

Grain Size and Texture Comparison

Polishing sand typically features finer grains ranging from 0.1 to 0.5 millimeters, providing a smoother texture ideal for delicate surface finishing and gentle abrasion. Blasting sand, on the other hand, has coarser grains between 0.5 and 2 millimeters, designed for more aggressive cleaning and surface preparation by effectively removing rust, paint, and other contaminants. The texture difference between polishing sand's fine, uniform grains and blasting sand's rough, irregular particles directly impacts their suitability for precision polishing versus heavy-duty abrasive blasting applications.

Key Applications of Polishing Sand

Polishing sand is primarily used in surface finishing applications where smoothness and shine are critical, such as in glass polishing, metal buffing, and stone refinement. Its fine grains effectively remove micro-abrasions and enhance surface clarity without causing damage. Unlike blasting sand, which focuses on aggressive material removal, polishing sand targets precision and detail to achieve high-quality, polished finishes.

Key Applications of Blasting Sand

Blasting sand is primarily used in industrial surface preparation processes such as removing rust, paint, and contaminants from metal structures to ensure optimal coating adhesion. It is widely applied in shipyards, automotive manufacturing, and construction for cleaning and shaping surfaces before painting or welding. This abrasive media is essential for heavy-duty cleaning tasks requiring high-pressure sandblasting to restore or prepare surfaces effectively.

Surface Finish Outcomes: Polishing vs Blasting

Polishing sand creates a smooth, glossy surface finish by gradually wearing down rough textures with fine abrasives, enhancing aesthetic appeal and tactile quality. Blasting sand produces a rough, matte surface by forcefully abrading the material, improving adhesion or preparing surfaces for coatings. The choice between polishing and blasting sand directly influences the surface texture, durability, and suitability for specific applications.

Performance Efficiency in Industrial Use

Polishing sand, characterized by its fine, uniform grains, offers superior surface finish and precision in industrial applications, enhancing performance efficiency through minimal abrasion and smooth texture. Blasting sand, with coarser, angular particles, excels in rapid material removal, providing higher impact force ideal for cleaning and surface preparation tasks. Selecting the appropriate sand type based on particle size and shape directly influences operational speed, energy consumption, and overall industrial productivity.

Safety Considerations for Each Sand Type

Polishing sand typically uses finer, less abrasive grains that reduce the risk of surface damage and inhalation hazards, making it safer for detailed work with appropriate protective equipment. Blasting sand, often coarser and more aggressive, poses higher risks such as silica dust exposure and surface erosion, requiring stringent safety measures including respiratory protection and controlled ventilation. Proper handling protocols and personal protective equipment are essential to mitigate health risks associated with both sand types.

Cost Analysis: Polishing Sand vs Blasting Sand

Polishing sand generally incurs higher costs due to finer grain quality and specialized processing required for smooth surface finishes, whereas blasting sand is more economical, predominantly used for abrasive cleaning and stripping tasks. The cost efficiency of blasting sand stems from its coarser grain size and ability to be reused multiple times without significant loss in performance, making it suitable for industrial-scale applications. Pricing for polishing sand can be 20-30% higher per ton compared to blasting sand due to labor-intensive preparation and purity standards demanded in fine polishing processes.

Selecting the Right Sand for Your Project

Polishing sand features fine, smooth grains ideal for achieving a glossy finish on surfaces like concrete and stone, enhancing aesthetic appeal and durability. Blasting sand is coarser and harder, designed to remove rust, paint, or debris effectively from metal and masonry through abrasive cleaning. Selecting the right sand depends on project requirements--use polishing sand for surface refinement and blasting sand for heavy-duty cleaning or preparation.

Polishing sand vs Blasting sand Infographic

materialdif.com

materialdif.com