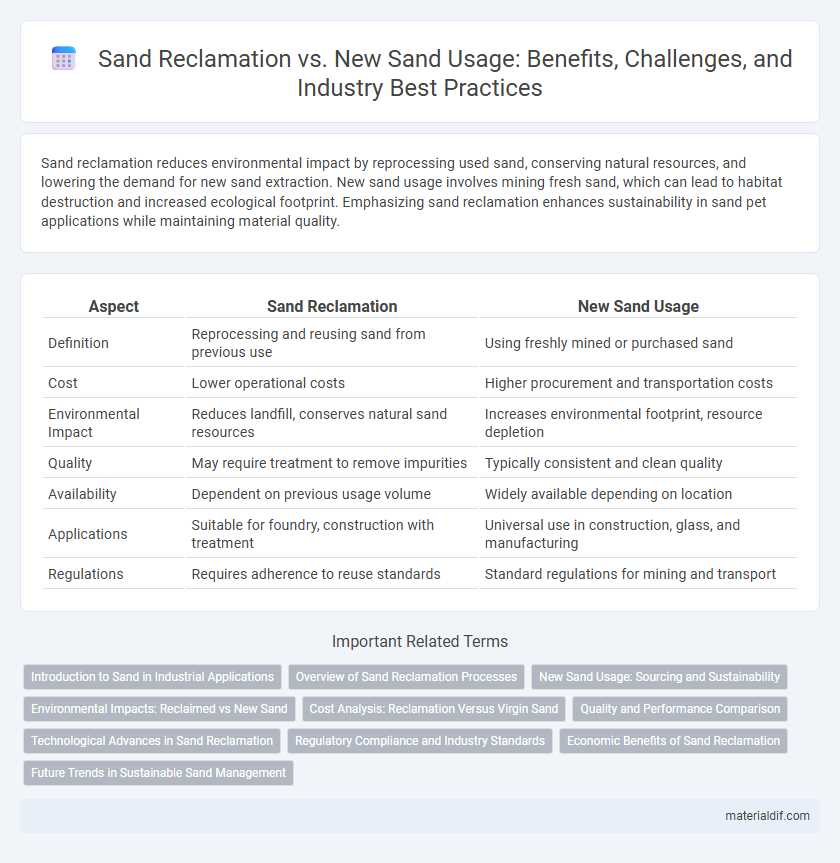

Sand reclamation reduces environmental impact by reprocessing used sand, conserving natural resources, and lowering the demand for new sand extraction. New sand usage involves mining fresh sand, which can lead to habitat destruction and increased ecological footprint. Emphasizing sand reclamation enhances sustainability in sand pet applications while maintaining material quality.

Table of Comparison

| Aspect | Sand Reclamation | New Sand Usage |

|---|---|---|

| Definition | Reprocessing and reusing sand from previous use | Using freshly mined or purchased sand |

| Cost | Lower operational costs | Higher procurement and transportation costs |

| Environmental Impact | Reduces landfill, conserves natural sand resources | Increases environmental footprint, resource depletion |

| Quality | May require treatment to remove impurities | Typically consistent and clean quality |

| Availability | Dependent on previous usage volume | Widely available depending on location |

| Applications | Suitable for foundry, construction with treatment | Universal use in construction, glass, and manufacturing |

| Regulations | Requires adherence to reuse standards | Standard regulations for mining and transport |

Introduction to Sand in Industrial Applications

Sand serves as a fundamental material in various industrial applications, including construction, glass manufacturing, and hydraulic fracturing. The reclamation of sand from used materials reduces environmental impact and conserves natural resources compared to relying solely on new sand extraction. Industrial sectors increasingly prioritize sand reclamation to enhance sustainability while maintaining material quality and performance standards.

Overview of Sand Reclamation Processes

Sand reclamation processes involve extracting and recycling used sand from foundries to reduce reliance on new sand resources, enhancing sustainability in manufacturing. Techniques such as thermal reclamation, mechanical reclamation, and wet reclamation help remove binders and contaminants, enabling the sand to be reused without compromising mold quality. Employing sand reclamation minimizes environmental impact, decreases raw material costs, and supports the circular economy in the casting industry.

New Sand Usage: Sourcing and Sustainability

New sand usage involves extracting virgin sand from natural sources such as riverbeds, coastal areas, and deserts, often leading to environmental degradation and habitat disruption. Sustainable sourcing prioritizes the use of regulatory frameworks and eco-friendly mining practices to minimize ecological impacts, ensuring the replenishment of sand resources. Innovations in alternative materials and recycling of construction waste reduce dependency on new sand, promoting long-term resource sustainability and conservation.

Environmental Impacts: Reclaimed vs New Sand

Reclaimed sand significantly reduces environmental degradation by minimizing the need for new sand extraction, which often leads to habitat destruction, groundwater depletion, and increased carbon emissions. New sand mining disrupts coastal and river ecosystems, causing sediment imbalance, erosion, and loss of biodiversity. Utilizing reclaimed sand supports sustainable construction practices by conserving natural resources and lowering the ecological footprint associated with sand production.

Cost Analysis: Reclamation Versus Virgin Sand

Sand reclamation significantly reduces material costs by repurposing existing resources, minimizing expenses associated with extraction and transportation of virgin sand. The initial investment in reclamation technology is offset by long-term savings and decreased environmental compliance costs linked to new sand mining. This cost-effective approach enhances sustainability while maintaining economic efficiency in construction and industrial applications.

Quality and Performance Comparison

Sand reclamation offers improved quality by removing impurities and restoring particle size distribution, resulting in more consistent strength and reduced defects in foundry applications. In contrast, new sand provides uniform granulometry and higher purity but often incurs higher costs and environmental impact due to extraction and processing. Performance tests reveal reclaimed sand can match or exceed new sand in mold stability and permeability when properly treated, making it a sustainable alternative without compromising casting quality.

Technological Advances in Sand Reclamation

Technological advances in sand reclamation have significantly improved the efficiency and sustainability of construction and industrial processes by enabling the reuse of sand from foundry molds and other applications. Innovative technologies such as thermal reclamation, mechanical attrition, and chemical treatments reduce the dependency on new sand extraction, conserving natural resources and minimizing environmental impacts. These advancements enhance the quality of reclaimed sand, ensuring it meets industry standards and supports circular economy goals in sectors like construction and metal casting.

Regulatory Compliance and Industry Standards

Sand reclamation processes reduce reliance on new sand extraction, supporting regulatory compliance with environmental protection standards and sustainable resource management. Industry standards such as ISO 14001 emphasize minimizing ecological impact and mandate regular monitoring of reclaimed sand quality to ensure safety and efficacy in construction and manufacturing applications. Adopting reclaimed sand aligns with government policies on reducing natural resource depletion and promotes adherence to global sustainability frameworks like the UN Sustainable Development Goals (SDGs).

Economic Benefits of Sand Reclamation

Sand reclamation significantly reduces costs associated with the extraction and transportation of new sand, leading to lower operational expenses in construction and manufacturing industries. Reclaimed sand can be reused multiple times without significant degradation in quality, enhancing resource efficiency and minimizing the demand for virgin sand deposits. This process supports sustainable economic growth by conserving natural resources while lowering material procurement budgets and environmental compliance costs.

Future Trends in Sustainable Sand Management

Sand reclamation reduces environmental degradation by reusing processed sand in construction, curbing the demand for new sand extraction from natural habitats. Advances in recycling technologies and policy frameworks are driving increased adoption of reclaimed sand, enhancing resource efficiency and lowering carbon footprints. Future trends emphasize integrated sand management systems combining reclamation, innovative materials, and regulatory measures to ensure sustainable supply chains in infrastructure development.

Sand reclamation vs New sand usage Infographic

materialdif.com

materialdif.com