Round grain sand features smooth, rounded particles that improve flowability and reduce compaction, making it ideal for applications requiring easy movement, such as in sandboxes or landscaping. Angular grain sand contains sharp, irregular-shaped particles that interlock, providing greater stability and strength, often preferred for construction and concrete mixing. Choosing between round and angular grain sand depends on the specific needs for drainage, compaction, and structural integrity.

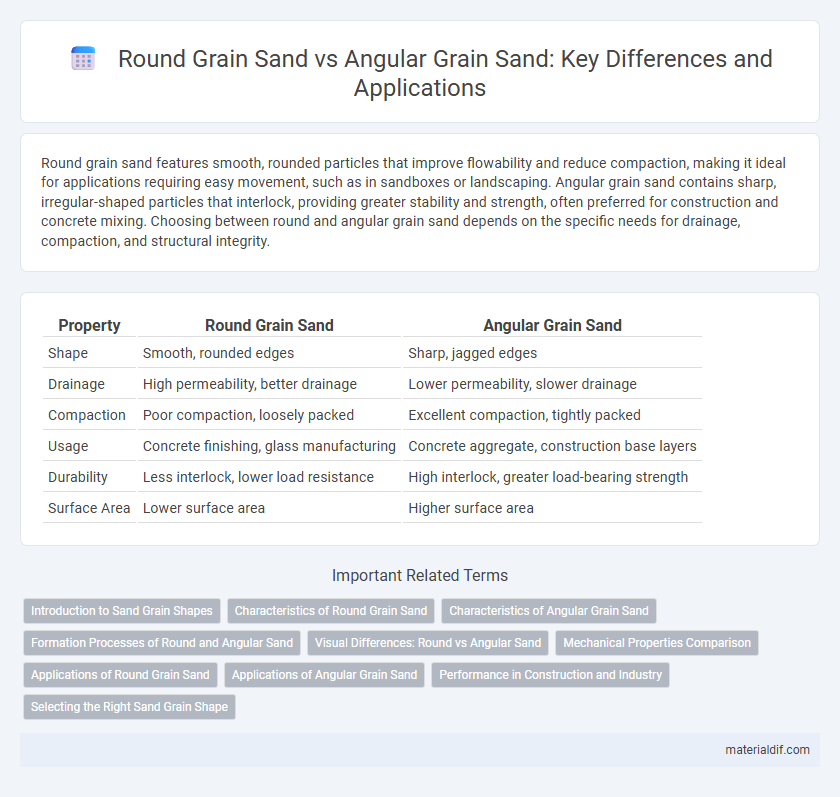

Table of Comparison

| Property | Round Grain Sand | Angular Grain Sand |

|---|---|---|

| Shape | Smooth, rounded edges | Sharp, jagged edges |

| Drainage | High permeability, better drainage | Lower permeability, slower drainage |

| Compaction | Poor compaction, loosely packed | Excellent compaction, tightly packed |

| Usage | Concrete finishing, glass manufacturing | Concrete aggregate, construction base layers |

| Durability | Less interlock, lower load resistance | High interlock, greater load-bearing strength |

| Surface Area | Lower surface area | Higher surface area |

Introduction to Sand Grain Shapes

Round grain sand features smooth, rounded edges formed by natural weathering and transportation processes, enhancing its flowability and compactness in construction applications. Angular grain sand consists of sharp, irregular edges resulting from minimal erosion, providing superior bonding strength in concrete and mortar. Understanding these distinct grain shapes influences material selection for specific engineering and landscaping projects.

Characteristics of Round Grain Sand

Round grain sand features smooth, rounded particles formed through extensive weathering and erosion, resulting in less surface area and reduced friction compared to angular grain sand. Its uniform shape enhances flowability and compaction, making it ideal for applications like concrete and filtration systems. The decreased interlocking ability of round grains provides lower mechanical stability but improved workability in construction materials.

Characteristics of Angular Grain Sand

Angular grain sand features sharp, irregular edges that create higher friction and better interlocking capabilities compared to round grain sand. This characteristic makes angular grain sand ideal for construction applications requiring strong bonding, such as concrete and mortar mixes. Its increased surface area improves adhesion with cement paste, enhancing structural durability and strength.

Formation Processes of Round and Angular Sand

Round grain sand forms primarily through prolonged weathering and water transport, where continuous abrasion smooths the edges, resulting in well-rounded particles often found in riverbeds and beaches. Angular grain sand originates from mechanical weathering and fracturing of rocks, preserving sharp edges due to limited transport or rapid deposition, commonly seen in desert or glacial environments. The differences in formation processes influence sand's texture, permeability, and suitability for various construction and industrial applications.

Visual Differences: Round vs Angular Sand

Round grain sand exhibits smooth, well-rounded edges due to prolonged weathering and transport, giving it a polished appearance that reflects light softly. Angular grain sand features sharp, jagged edges with irregular shapes from minimal weathering, resulting in a rough texture that scatters light unevenly. These visual differences influence the sand's aesthetic and suitability for applications like concrete or landscaping.

Mechanical Properties Comparison

Round grain sand exhibits lower inter-particle friction compared to angular grain sand, resulting in reduced shear strength and compaction efficiency. Angular grain sand provides superior mechanical interlocking, enhancing load-bearing capacity and stability in construction applications. The choice between round and angular grains significantly influences concrete strength, permeability, and durability.

Applications of Round Grain Sand

Round grain sand is preferred in applications requiring good flowability and reduced compaction, such as in concrete production and filtration systems. Its smooth texture enhances particle movement, making it ideal for use in landscaping, playgrounds, and sandblasting where minimal abrasion is desired. This type of sand also supports better drainage in construction projects and provides comfort in recreational areas due to its softer consistency.

Applications of Angular Grain Sand

Angular grain sand offers superior mechanical bonding and increased surface area compared to round grain sand, making it ideal for concrete and mortar applications requiring enhanced strength and durability. Its irregular shape improves interlocking properties, which is essential in construction materials and abrasive blasting processes. Industries such as road base production, masonry, and asphalt rely on angular grain sand to achieve optimal compaction and structural integrity.

Performance in Construction and Industry

Round grain sand exhibits superior flowability and workability in concrete mixes, enhancing ease of placement and reducing water demand, which improves overall strength and durability. Angular grain sand provides better interlock and mechanical bonding, increasing shear strength and stability in structural applications such as masonry and asphalt. Choosing between round and angular grains depends on balancing concrete workability with structural performance requirements in construction and industrial projects.

Selecting the Right Sand Grain Shape

Selecting the right sand grain shape depends on the application: round grain sand offers better workability and flow due to its smooth texture, making it ideal for concrete and plaster work. Angular grain sand provides superior bonding strength and stability, preferred for mortar and asphalt mixtures where enhanced adhesion is crucial. Understanding the differences in grain shape impacts the overall durability and performance of construction materials.

Round grain sand vs Angular grain sand Infographic

materialdif.com

materialdif.com