Reclaimed sand offers a sustainable alternative to virgin sand by reducing the demand for natural resources and minimizing environmental degradation from excessive mining. This recycled material maintains comparable strength and durability, making it suitable for construction and manufacturing applications. Choosing reclaimed sand helps conserve ecosystems and supports more eco-friendly building practices, contributing to long-term resource management.

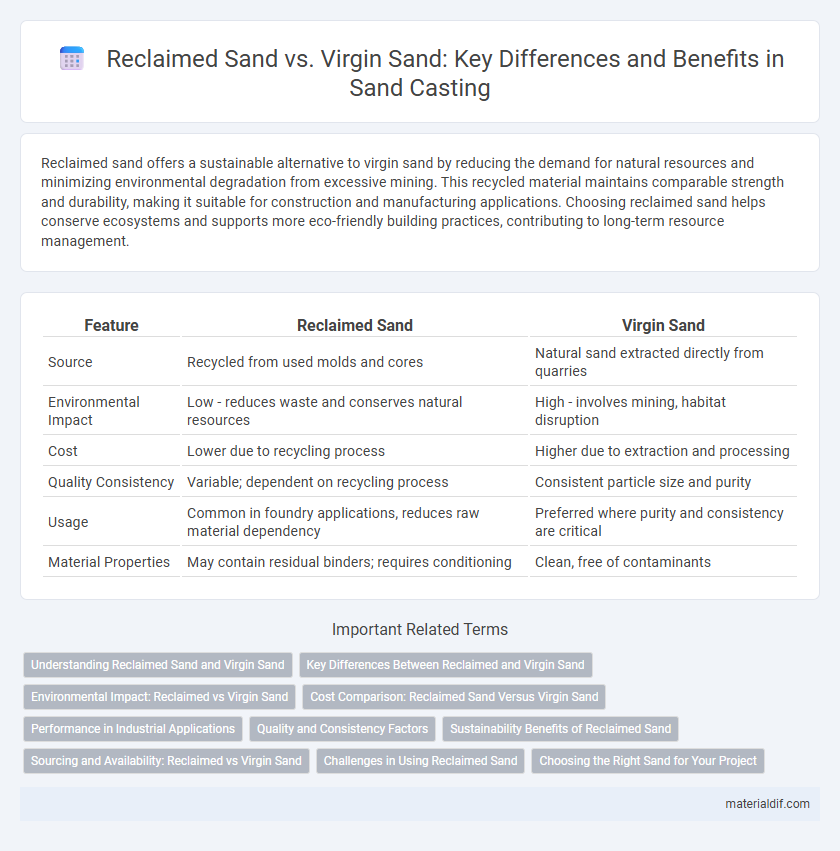

Table of Comparison

| Feature | Reclaimed Sand | Virgin Sand |

|---|---|---|

| Source | Recycled from used molds and cores | Natural sand extracted directly from quarries |

| Environmental Impact | Low - reduces waste and conserves natural resources | High - involves mining, habitat disruption |

| Cost | Lower due to recycling process | Higher due to extraction and processing |

| Quality Consistency | Variable; dependent on recycling process | Consistent particle size and purity |

| Usage | Common in foundry applications, reduces raw material dependency | Preferred where purity and consistency are critical |

| Material Properties | May contain residual binders; requires conditioning | Clean, free of contaminants |

Understanding Reclaimed Sand and Virgin Sand

Reclaimed sand is processed from used foundry sand, offering sustainable reuse by reducing landfill waste and conserving natural resources, while virgin sand is newly extracted from quarries, characterized by its consistent grain size and high purity. Reclaimed sand typically has altered physical and chemical properties due to heat and binder degradation, which can impact its performance in casting processes compared to virgin sand's predictable behavior. Understanding the differences in composition, environmental impact, and cost-effectiveness helps industries choose the appropriate sand type for specific applications in metal casting and construction.

Key Differences Between Reclaimed and Virgin Sand

Reclaimed sand is recycled from construction waste or dredged materials, making it environmentally sustainable, while virgin sand is naturally sourced from riverbeds or quarries, ensuring consistent grain quality. Virgin sand typically offers higher purity and uniform texture compared to reclaimed sand, which may contain impurities or altered particle shapes. The choice between reclaimed and virgin sand depends on factors such as cost, environmental impact, and specific construction requirements.

Environmental Impact: Reclaimed vs Virgin Sand

Reclaimed sand significantly reduces environmental degradation compared to virgin sand, as it minimizes the need for extensive mining operations that disturb natural habitats and ecosystems. Using reclaimed sand lowers carbon emissions and energy consumption by decreasing the demand for raw material extraction and processing. Furthermore, reclaimed sand helps preserve biodiversity and reduces soil erosion, promoting sustainable construction practices.

Cost Comparison: Reclaimed Sand Versus Virgin Sand

Reclaimed sand often presents a cost-effective alternative to virgin sand, primarily due to reduced extraction and processing expenses. While virgin sand requires extensive mining and transportation, increasing overall project costs, reclaimed sand is sourced from recycled materials, lowering procurement and environmental remediation fees. However, variability in quality and availability can influence pricing, making thorough assessment essential for accurate cost comparison.

Performance in Industrial Applications

Reclaimed sand demonstrates enhanced performance in industrial applications due to its improved moldability and reduced permeability compared to virgin sand, which often requires additional processing. The recycling process removes impurities and binders, resulting in a more consistent grain structure that supports better compaction and surface finish in casting operations. Industrial studies show that using reclaimed sand can lead to higher dimensional accuracy and reduced defects, improving overall production efficiency.

Quality and Consistency Factors

Reclaimed sand offers greater environmental benefits but often shows variability in grain size and purity compared to virgin sand, which maintains consistent high quality due to controlled extraction processes. Virgin sand ensures uniform particle shape, hardness, and minimal organic content, critical for construction and industrial applications requiring precise material specifications. The quality consistency of virgin sand reduces the risk of impurities affecting the structural integrity of concrete or glass products, while reclaimed sand may require additional processing to meet the same standards.

Sustainability Benefits of Reclaimed Sand

Reclaimed sand significantly reduces the depletion of natural resources by minimizing the extraction of virgin sand from riverbeds and quarries, preserving ecosystems and biodiversity. Its reuse lowers carbon emissions associated with mining, transportation, and processing, contributing to a smaller environmental footprint in construction projects. Incorporating reclaimed sand promotes circular economy principles by diverting waste materials from landfills and reducing the demand for raw materials in concrete and asphalt production.

Sourcing and Availability: Reclaimed vs Virgin Sand

Reclaimed sand is sourced from construction and demolition waste, offering a sustainable alternative that reduces environmental impact and reliance on natural reserves. Virgin sand is extracted from riverbeds, quarries, and coastal areas, making its availability dependent on geographical location and subject to depletion concerns. The consistent supply of reclaimed sand depends on urban development cycles, while virgin sand availability faces stricter regulations due to ecological preservation efforts.

Challenges in Using Reclaimed Sand

Reclaimed sand faces challenges such as inconsistent grain size and residual impurities that affect its binding properties and overall strength in construction applications. The presence of fines and binders can lead to decreased permeability and compaction issues, resulting in lower quality and durability compared to virgin sand. Proper processing and thorough quality control are essential to mitigate these challenges for effective reuse in industrial molding and concrete production.

Choosing the Right Sand for Your Project

Reclaimed sand offers a sustainable alternative by recycling used materials, reducing environmental impact and lowering costs, making it ideal for eco-conscious construction projects. Virgin sand, sourced directly from natural deposits, provides consistent grain size and purity essential for high-strength concrete and precision masonry work. Evaluating project requirements, including structural integrity and environmental goals, ensures the selection of the appropriate sand type for optimal performance.

Reclaimed sand vs Virgin sand Infographic

materialdif.com

materialdif.com