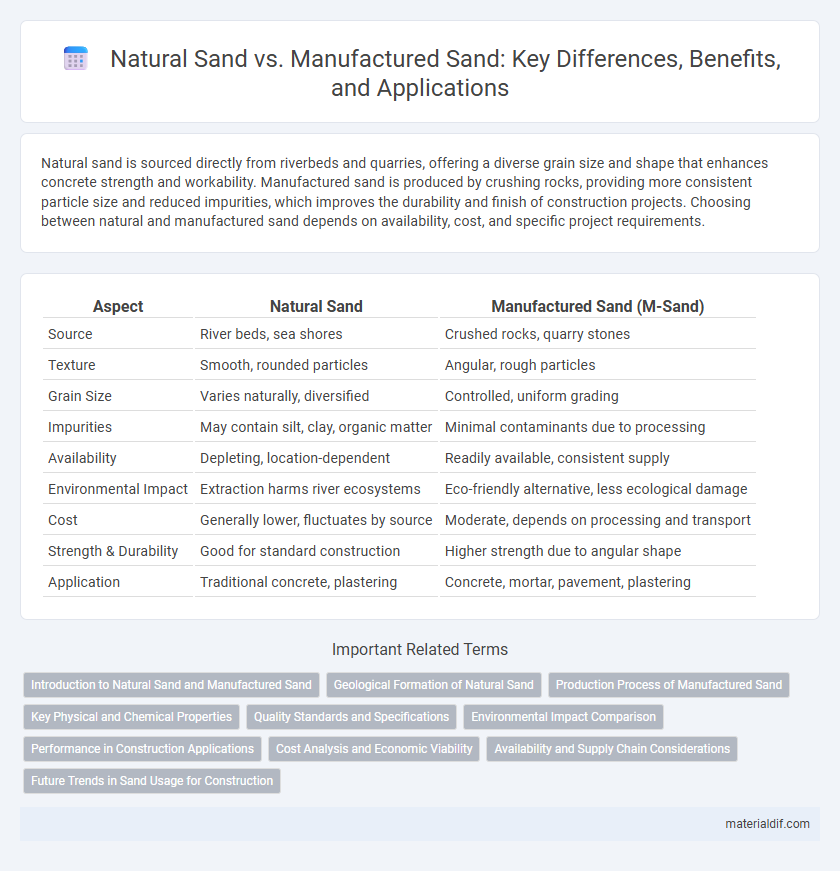

Natural sand is sourced directly from riverbeds and quarries, offering a diverse grain size and shape that enhances concrete strength and workability. Manufactured sand is produced by crushing rocks, providing more consistent particle size and reduced impurities, which improves the durability and finish of construction projects. Choosing between natural and manufactured sand depends on availability, cost, and specific project requirements.

Table of Comparison

| Aspect | Natural Sand | Manufactured Sand (M-Sand) |

|---|---|---|

| Source | River beds, sea shores | Crushed rocks, quarry stones |

| Texture | Smooth, rounded particles | Angular, rough particles |

| Grain Size | Varies naturally, diversified | Controlled, uniform grading |

| Impurities | May contain silt, clay, organic matter | Minimal contaminants due to processing |

| Availability | Depleting, location-dependent | Readily available, consistent supply |

| Environmental Impact | Extraction harms river ecosystems | Eco-friendly alternative, less ecological damage |

| Cost | Generally lower, fluctuates by source | Moderate, depends on processing and transport |

| Strength & Durability | Good for standard construction | Higher strength due to angular shape |

| Application | Traditional concrete, plastering | Concrete, mortar, pavement, plastering |

Introduction to Natural Sand and Manufactured Sand

Natural sand is derived from the erosion of rocks and minerals, typically extracted from riverbeds, beaches, or quarries, providing coarse aggregates essential for concrete and construction. Manufactured sand, also known as crushed sand, is produced by mechanically crushing rocks, often granite or basalt, to achieve specific particle sizes for uniformity and strength in building applications. Both types serve as vital materials in construction, with natural sand offering a more rounded texture while manufactured sand provides controlled grading and angularity.

Geological Formation of Natural Sand

Natural sand forms through the weathering and erosion of rocks over millions of years, resulting in particles with diverse mineral compositions and rounded shapes due to prolonged water or wind action. This geological process imparts natural sand with variable grain sizes and smooth textures, which affect its suitability in construction applications. Manufactured sand, in contrast, is artificially processed by crushing rocks, lacking the natural sedimentary layering and often exhibiting more angular particles.

Production Process of Manufactured Sand

Manufactured sand is produced by crushing hard granite or basalt rocks using advanced crushing machines, followed by screening to achieve specific particle sizes. The production process includes stages like primary crushing, secondary crushing, and washing to remove impurities and fine particles, ensuring consistent quality. This method allows precise control over sand gradation and shape, making it a reliable alternative to natural sand for construction purposes.

Key Physical and Chemical Properties

Natural sand exhibits a well-rounded shape with smooth surfaces, high silica content typically above 70%, and minimal clay particles, contributing to superior workability and strength in construction. Manufactured sand, produced by crushing hard rocks, tends to have a more angular shape, higher fines content, and varied mineral composition, which can influence water demand and bonding characteristics. Chemically, natural sand is relatively inert with low soluble salts, whereas manufactured sand may contain higher levels of reactive silica and impurities affecting durability and cement hydration.

Quality Standards and Specifications

Natural sand, sourced from riverbeds or quarries, must meet stringent quality standards such as particle size distribution, cleanliness, and durability to ensure its suitability for construction. Manufactured sand, produced by crushing rocks, offers consistent quality and controlled gradation, complying with specifications like IS 383 and ASTM C33 for optimal strength and workability in concrete mixes. Both types require thorough testing for contaminants and adherence to specific limits on silt content, shape, and fineness modulus to maintain structural integrity and long-term performance.

Environmental Impact Comparison

Natural sand extraction severely disrupts river ecosystems, causing habitat loss and increased sedimentation, while manufactured sand production typically consumes more energy and generates dust pollution. Environmental assessments indicate natural sand mining leads to water quality degradation and biodiversity decline, whereas manufactured sand, when sourced responsibly, mitigates resource depletion but requires strict emission controls. Life cycle analyses reveal that incorporating recycled materials into manufactured sand reduces carbon footprint, offering a sustainable alternative to excessive natural sand extraction.

Performance in Construction Applications

Natural sand exhibits superior particle shape and smooth texture, enhancing workability and concrete strength in construction applications. Manufactured sand, produced by crushing rocks, offers consistent grading and angular particles, improving bonding and reducing voids in concrete mixes. Performance depends on project requirements, with manufactured sand favored for durability and natural sand preferred for finish quality.

Cost Analysis and Economic Viability

Natural sand typically incurs lower initial extraction costs compared to manufactured sand, which requires machinery and processing. However, fluctuating availability and environmental regulations can increase the long-term expenses of natural sand procurement. Manufactured sand offers more consistent quality and supply, often resulting in better economic viability for large-scale construction projects despite higher upfront costs.

Availability and Supply Chain Considerations

Natural sand, sourced directly from riverbeds and quarries, often faces issues related to depletion and environmental regulations that limit its availability and disrupt supply chains. Manufactured sand, produced by crushing rocks, offers a more consistent and controllable supply, especially in regions where natural sand extraction is restricted or inadequate. The supply chain for manufactured sand typically benefits from proximity to industrial facilities, reducing transportation costs and buffering against natural scarcity.

Future Trends in Sand Usage for Construction

Natural sand demand faces sustainability challenges due to environmental regulations and depletion of riverbeds, urging the construction industry to adopt manufactured sand as a viable alternative. Manufactured sand, produced by crushing hard granite or basalt rocks, offers controlled particle size and shape, enhancing concrete strength and durability while minimizing ecological impact. Advancements in production technology and increasing infrastructure projects globally are driving the trend toward higher utilization of manufactured sand in future construction applications.

Natural sand vs Manufactured sand Infographic

materialdif.com

materialdif.com