Quartz sand consists primarily of natural, crystalline silica particles that retain their angular shape, making it ideal for filtration and abrasive applications. Glass sand, derived from melting quartz sand at high temperatures, features a more uniform, rounded grain structure suitable for manufacturing glass products. The purity and grain size of quartz sand influence the clarity and strength of the glass produced from glass sand.

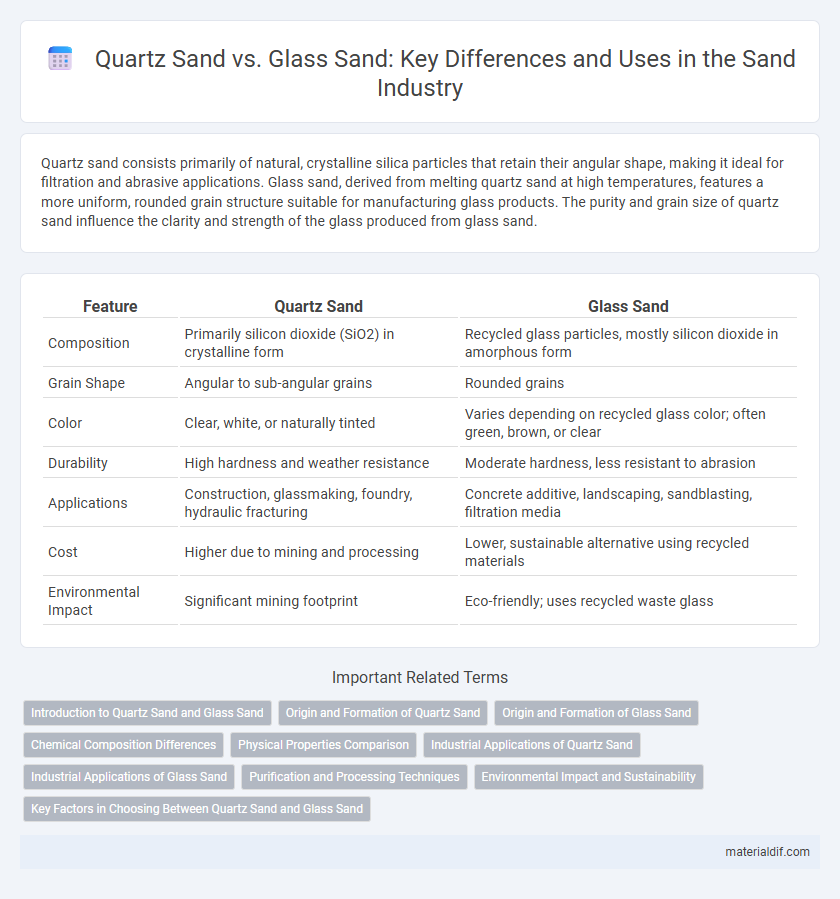

Table of Comparison

| Feature | Quartz Sand | Glass Sand |

|---|---|---|

| Composition | Primarily silicon dioxide (SiO2) in crystalline form | Recycled glass particles, mostly silicon dioxide in amorphous form |

| Grain Shape | Angular to sub-angular grains | Rounded grains |

| Color | Clear, white, or naturally tinted | Varies depending on recycled glass color; often green, brown, or clear |

| Durability | High hardness and weather resistance | Moderate hardness, less resistant to abrasion |

| Applications | Construction, glassmaking, foundry, hydraulic fracturing | Concrete additive, landscaping, sandblasting, filtration media |

| Cost | Higher due to mining and processing | Lower, sustainable alternative using recycled materials |

| Environmental Impact | Significant mining footprint | Eco-friendly; uses recycled waste glass |

Introduction to Quartz Sand and Glass Sand

Quartz sand primarily consists of silicon dioxide (SiO2) crystals, renowned for their high purity and hardness, making it essential in industries such as glass manufacturing, construction, and water filtration. Glass sand, often a refined form of quartz sand, is characterized by its uniform grain size, low impurities, and high silica content, ensuring optimal melting properties for producing clear, strong glass. Understanding the differences in composition and quality between quartz sand and glass sand is crucial for selecting the appropriate material in industrial applications.

Origin and Formation of Quartz Sand

Quartz sand primarily originates from the weathering and erosion of quartz-rich rocks such as granite and sandstone, where physical and chemical processes break down the minerals into fine, durable grains. Its formation involves the abrasion and transport of quartz particles by wind, water, or ice, leading to well-rounded, high-purity sand deposits ideal for various industrial uses. Unlike glass sand, which can be artificially processed or composed of mixed silicate minerals, quartz sand's natural origin guarantees a consistent crystalline structure crucial for glass manufacturing and filtration applications.

Origin and Formation of Glass Sand

Glass sand primarily originates from high-purity quartz deposits formed over millions of years through the weathering and erosion of granite and sandstone. This sand undergoes natural processes such as mechanical weathering and sedimentation, concentrating silica dioxide (SiO2) content essential for glass manufacturing. Unlike typical quartz sand, glass sand exhibits minimal impurities like iron oxide, ensuring clarity and durability in the final glass products.

Chemical Composition Differences

Quartz sand primarily consists of silicon dioxide (SiO2) in its crystalline form, offering high purity and minimal impurities. Glass sand, while also rich in silicon dioxide, contains additional compounds like calcium oxide (CaO), sodium oxide (Na2O), and aluminum oxide (Al2O3), which lower its melting point and improve the glass-making process. The chemical composition differences influence their application suitability; quartz sand is preferred in foundry and industrial uses requiring high thermal resistance, whereas glass sand is optimized for glass manufacture due to its fluxing agents.

Physical Properties Comparison

Quartz sand exhibits high hardness with a Mohs scale rating of 7, making it more resistant to abrasion than glass sand, which generally rates lower on the hardness scale. Quartz sand has a higher melting point around 1670degC, whereas glass sand melts at approximately 1400degC due to its silica and soda-lime composition. The grain shape of quartz sand is typically angular and well-defined, enhancing stability in construction, while glass sand is often more rounded and smoother, impacting compaction and bonding in materials.

Industrial Applications of Quartz Sand

Quartz sand is widely preferred in industrial applications due to its high silica content (over 90%), chemical purity, and hardness, making it essential for glass manufacturing, foundry molds, and hydraulic fracturing. Its consistent grain size and resistance to weathering enhance durability and efficiency in producing high-quality glass, ceramics, and abrasives. Glass sand, while similar, typically lacks the purity and granulometry standards necessary for advanced industrial uses, limiting its suitability in precision-dependent processes.

Industrial Applications of Glass Sand

Glass sand, primarily composed of high-purity silica (SiO2), is essential for the manufacture of container glass, flat glass, and specialty glass products due to its low iron content and exceptional clarity. Unlike quartz sand, which is often used in construction and foundry applications, glass sand undergoes rigorous processing to meet strict industrial standards for transparency and chemical stability. Its industrial applications extend to fiberglass production, optical fibers, and silicon-based semiconductors, highlighting its critical role in advanced manufacturing sectors.

Purification and Processing Techniques

Quartz sand undergoes rigorous purification processes including acid washing, magnetic separation, and flotation to remove impurities like iron oxides and clay minerals, ensuring high silica content suitable for industrial applications. Glass sand requires intensive processing steps such as sieving, washing, and sometimes chemical treatment to achieve the necessary purity and particle size for glass manufacturing. Advanced techniques like hydrocycloning and density separation optimize the removal of contaminants, enhancing the performance and quality of quartz and glass sand in their respective uses.

Environmental Impact and Sustainability

Quartz sand extraction typically causes less environmental degradation compared to glass sand mining, as it often involves surface deposits that require minimal processing. Glass sand production demands higher energy inputs and chemical treatments, leading to increased carbon emissions and potential water contamination. Sustainable sourcing of quartz sand supports lower ecological footprints and promotes the preservation of natural habitats.

Key Factors in Choosing Between Quartz Sand and Glass Sand

Quartz sand offers superior hardness and chemical resistance, making it ideal for industrial applications requiring durability and minimal contamination. Glass sand features a finer grain size and higher purity, which enhances clarity and melting efficiency in glass manufacturing. Key factors in choosing between quartz and glass sand include grain size, silica content, and thermal properties aligned with specific usage requirements.

Quartz sand vs Glass sand Infographic

materialdif.com

materialdif.com