M-Sand, or manufactured sand, is produced by crushing hard granite rocks and is known for its consistent particle size, making it ideal for concrete production due to its higher strength and durability. P-Sand, or pit sand, is naturally sourced from river beds with a coarser texture, which makes it suitable for plastering but less desirable for structural concrete because of impurities and variability. Choosing between M-Sand and P-Sand depends on the specific construction requirements, where M-Sand offers better quality control and environmental benefits.

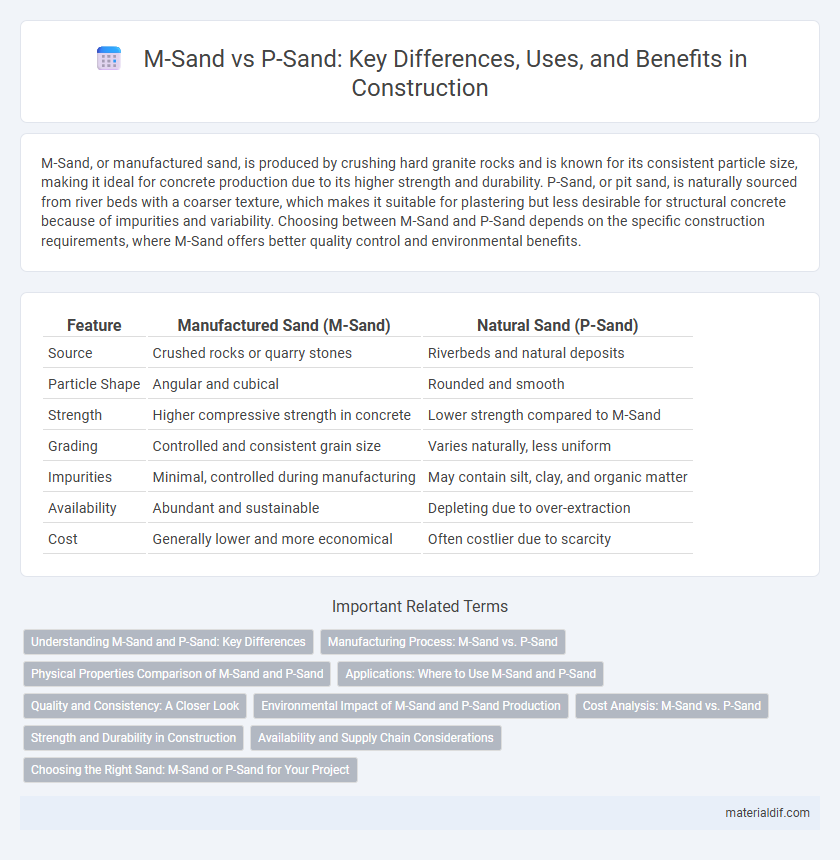

Table of Comparison

| Feature | Manufactured Sand (M-Sand) | Natural Sand (P-Sand) |

|---|---|---|

| Source | Crushed rocks or quarry stones | Riverbeds and natural deposits |

| Particle Shape | Angular and cubical | Rounded and smooth |

| Strength | Higher compressive strength in concrete | Lower strength compared to M-Sand |

| Grading | Controlled and consistent grain size | Varies naturally, less uniform |

| Impurities | Minimal, controlled during manufacturing | May contain silt, clay, and organic matter |

| Availability | Abundant and sustainable | Depleting due to over-extraction |

| Cost | Generally lower and more economical | Often costlier due to scarcity |

Understanding M-Sand and P-Sand: Key Differences

M-Sand (Manufactured Sand) is produced by crushing hard granite stones, offering consistent size and shape, while P-Sand (Pit Sand) is naturally sourced from riverbeds and is coarser with irregular particles. M-Sand provides better workability, strength, and durability due to its controlled gradation and absence of silt, unlike P-Sand which may contain impurities affecting construction quality. These distinctions make M-Sand preferable for modern concrete production, enhancing structural integrity and sustainability.

Manufacturing Process: M-Sand vs. P-Sand

Manufactured Sand (M-Sand) is produced by crushing hard granite stones using advanced machinery, ensuring a consistent particle size and high strength suitable for concrete and construction. Natural Pit Sand (P-Sand) is obtained from river beds through mining, which may contain impurities like silt and clay, affecting its quality and durability. The controlled manufacturing process of M-Sand results in better gradation and reduced environmental impact compared to the extraction methods of P-Sand.

Physical Properties Comparison of M-Sand and P-Sand

M-Sand (Manufactured Sand) exhibits higher density and uniform particle size compared to P-Sand (Pit Sand), which often contains irregular, coarse grains and impurities. The physical properties of M-Sand include consistent fineness modulus, reduced water absorption, and better angularity, enhancing concrete strength and durability. P-Sand typically shows greater variability in grain shape and size, leading to lower compressive strength and increased voids in mortar or concrete mixes.

Applications: Where to Use M-Sand and P-Sand

M-Sand, manufactured from crushed rock, is ideal for concrete production, plastering, and masonry work due to its consistent grain size and strength. P-Sand, derived from riverbeds, is preferred for brickwork, plastering, and filling applications where a smoother finish is essential. Choosing between M-Sand and P-Sand depends on the structural requirement, with M-Sand favored for strength-critical projects and P-Sand used for aesthetic and finishing purposes.

Quality and Consistency: A Closer Look

M-Sand (Manufactured Sand) offers superior quality and consistency compared to P-Sand (Pit Sand) due to controlled production processes and strict quality checks. M-Sand particles are well-shaped and uniformly graded, leading to stronger concrete with better workability and reduced voids. P-Sand often contains impurities and varies in grain size, which can compromise construction durability and structural integrity.

Environmental Impact of M-Sand and P-Sand Production

Manufacturing M-Sand (Manufactured Sand) significantly reduces the environmental degradation caused by the extraction of P-Sand (Pit Sand), which often leads to riverbed depletion and habitat loss. The production of M-Sand recycles quarry waste and minimizes land disruption, lowering dust emissions and water pollution compared to traditional sand mining. This eco-friendly approach helps conserve natural resources and supports sustainable construction practices by reducing the ecological footprint of sand harvesting.

Cost Analysis: M-Sand vs. P-Sand

Manufactured sand (M-Sand) typically costs slightly more than natural pit sand (P-Sand) due to the processing and quality control involved in its production. However, M-Sand offers consistent particle size and fewer impurities, potentially reducing construction defects and long-term repair costs. The overall cost-effectiveness of M-Sand versus P-Sand depends on project scale, availability, and transportation expenses.

Strength and Durability in Construction

M-Sand exhibits higher strength and durability in construction due to its consistent grain size and angular shape, which enhances bonding with cement. P-Sand, derived from natural riverbeds, often contains impurities and flaky particles that can weaken concrete structures over time. Utilizing M-Sand improves structural integrity and longevity compared to traditional P-Sand in building projects.

Availability and Supply Chain Considerations

M-Sand, or manufactured sand, is produced by crushing hard granite stones, making its availability consistent and less dependent on natural deposits, which are depleting rapidly. P-Sand, or pit sand, is sourced from riverbeds and pits, leading to irregular supply due to environmental regulations and seasonal fluctuations. The supply chain for M-Sand benefits from controlled production processes and proximity to urban construction sites, ensuring steady availability compared to the variable and often limited supply routes of P-Sand.

Choosing the Right Sand: M-Sand or P-Sand for Your Project

M-Sand, or Manufactured Sand, is produced by crushing hard granite rocks, offering uniform particle size and higher strength, making it ideal for concrete and structural projects needing durability. P-Sand, or River Sand, extracted from river beds, features smoother texture and is preferred for plastering and masonry work due to its fine grains and natural shape. Selecting between M-Sand and P-Sand depends on project requirements such as strength, texture, and cost-efficiency, with M-Sand favored for robust construction and P-Sand suited for finishing and aesthetic purposes.

M-Sand vs P-Sand Infographic

materialdif.com

materialdif.com