Green sand consists of a mixture of sand, clay, water, and other additives, offering excellent moldability and cost-effectiveness for metal casting processes. Resin sand uses a synthetic binder that provides superior strength, better surface finish, and higher dimensional accuracy, making it ideal for complex or high-precision castings. Choosing between green sand and resin sand depends on factors like casting complexity, production volume, and desired surface quality.

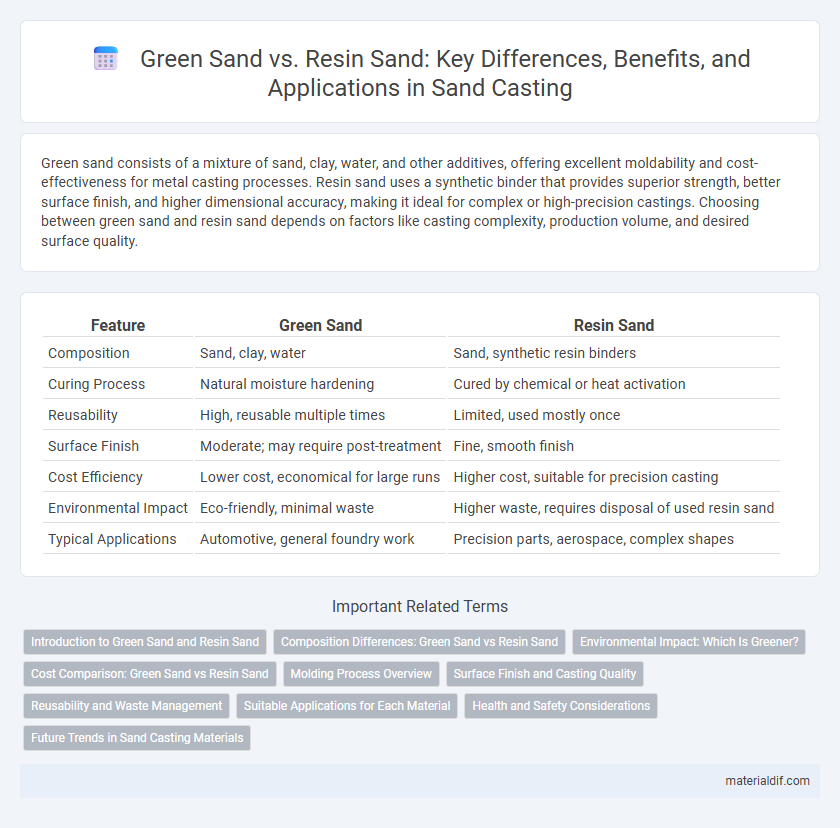

Table of Comparison

| Feature | Green Sand | Resin Sand |

|---|---|---|

| Composition | Sand, clay, water | Sand, synthetic resin binders |

| Curing Process | Natural moisture hardening | Cured by chemical or heat activation |

| Reusability | High, reusable multiple times | Limited, used mostly once |

| Surface Finish | Moderate; may require post-treatment | Fine, smooth finish |

| Cost Efficiency | Lower cost, economical for large runs | Higher cost, suitable for precision casting |

| Environmental Impact | Eco-friendly, minimal waste | Higher waste, requires disposal of used resin sand |

| Typical Applications | Automotive, general foundry work | Precision parts, aerospace, complex shapes |

Introduction to Green Sand and Resin Sand

Green sand consists of silica sand, clay, water, and other additives, forming a mold material that is naturally moist and reusable. Resin sand, also known as chemically bonded sand, uses synthetic organic binders like phenolic or furan resins to create a stronger, more rigid mold with enhanced dimensional stability. Green sand provides cost-effective and environmentally friendly casting solutions, while resin sand excels in applications requiring higher precision and intricate detail.

Composition Differences: Green Sand vs Resin Sand

Green sand primarily consists of silica sand, clay, water, and bentonite, creating a naturally moist and pliable mixture ideal for casting molds. Resin sand uses silica sand bonded with chemical resins like phenolic or furan resin, which hardens through heat or catalysts to provide higher strength and better surface finish. These distinct compositions influence mold strength, permeability, and the ability to achieve intricate casting details.

Environmental Impact: Which Is Greener?

Green sand casting uses natural sand combined with clay and water, making it more environmentally friendly due to its recyclability and lower chemical emissions. Resin sand involves synthetic binders that release volatile organic compounds (VOCs) during curing, contributing to higher environmental pollution and more complex disposal processes. The biodegradability and ease of reuse of green sand significantly reduce its ecological footprint compared to the resin sand method.

Cost Comparison: Green Sand vs Resin Sand

Green sand offers a cost-effective solution with lower raw material expenses and simpler reuse processes, making it ideal for small to medium production runs. Resin sand typically incurs higher costs due to the expense of resin binders and specialized reclamation equipment but delivers superior surface finish and dimensional accuracy suitable for large-scale or complex castings. Evaluating production volume and casting requirements is crucial when balancing the upfront and operational costs between green sand and resin sand molding methods.

Molding Process Overview

Green sand molding uses a mixture of sand, clay, water, and additives to create a reusable mold, offering flexibility and cost-effectiveness in casting processes. Resin sand molding employs chemically bonded sand with resin binders, providing higher mold strength and better surface finish for complex or precision castings. Green sand is ideal for short production runs with moderate detail, while resin sand suits intricate patterns requiring dimensional accuracy and smoother surfaces.

Surface Finish and Casting Quality

Green sand provides a rougher surface finish due to its moisture content, which can cause minor defects but offers good dimensional accuracy and recyclability. Resin sand produces a smoother surface finish and superior casting quality with fewer imperfections, making it ideal for complex shapes and detailed castings. The choice between green sand and resin sand depends on the desired balance between cost-effectiveness and the precision of the final cast product.

Reusability and Waste Management

Green sand, composed mainly of silica sand, clay, water, and additives, offers high reusability rates due to its natural binder system, enabling multiple recycling cycles with minimal degradation in molding quality. Resin sand, bonded with synthetic resins, provides superior mold strength but presents challenges in waste management as spent resin-bonded sand requires specialized disposal or reclamation processes to mitigate environmental impact. Prioritizing green sand in foundry operations enhances sustainability by reducing waste generation and promoting efficient sand reclamation systems.

Suitable Applications for Each Material

Green sand is ideal for large-scale, low-cost casting processes such as automotive engine blocks and agricultural equipment, where its ability to be reused multiple times and its excellent collapsibility minimize costs. Resin sand excels in precision casting applications like aerospace components and intricate industrial parts due to its superior dimensional accuracy and strength, allowing for complex geometries and fine surface finishes. The choice between green sand and resin sand depends on the balance between production volume, detail required, and cost efficiency for specific foundry projects.

Health and Safety Considerations

Green sand, composed primarily of silica sand, clay, water, and additives, poses health risks due to silica dust exposure, which can cause respiratory issues and silicosis if inhaled over time. Resin sand, bonded with synthetic resins, reduces dust generation, lowering respiratory hazards but may emit volatile organic compounds (VOCs) during curing, requiring proper ventilation to mitigate inhalation risks. Both materials necessitate appropriate personal protective equipment (PPE) and adherence to occupational safety standards to ensure worker health and safety in foundry environments.

Future Trends in Sand Casting Materials

Green sand remains popular in sand casting due to its cost-effectiveness and recyclability, while resin sand gains traction for its superior mold strength and precision in complex castings. Emerging trends emphasize eco-friendly binders and hybrid materials that combine the sustainability of green sand with the performance benefits of resin sand. Innovations in additive manufacturing and chemical additives are driving the evolution of sand casting materials toward higher efficiency and reduced environmental impact.

Green Sand vs Resin Sand Infographic

materialdif.com

materialdif.com