Resin-coated sand offers superior mold stability and cleaner casting surfaces compared to green sand, which is a traditional mixture of sand, clay, and water. While green sand is cost-effective and widely used in foundries for its good permeability and reusability, resin-coated sand enhances precision and reduces defects such as sand inclusions and erosion. Choosing between the two depends on the specific casting requirements, balancing cost with the need for higher quality and dimensional accuracy.

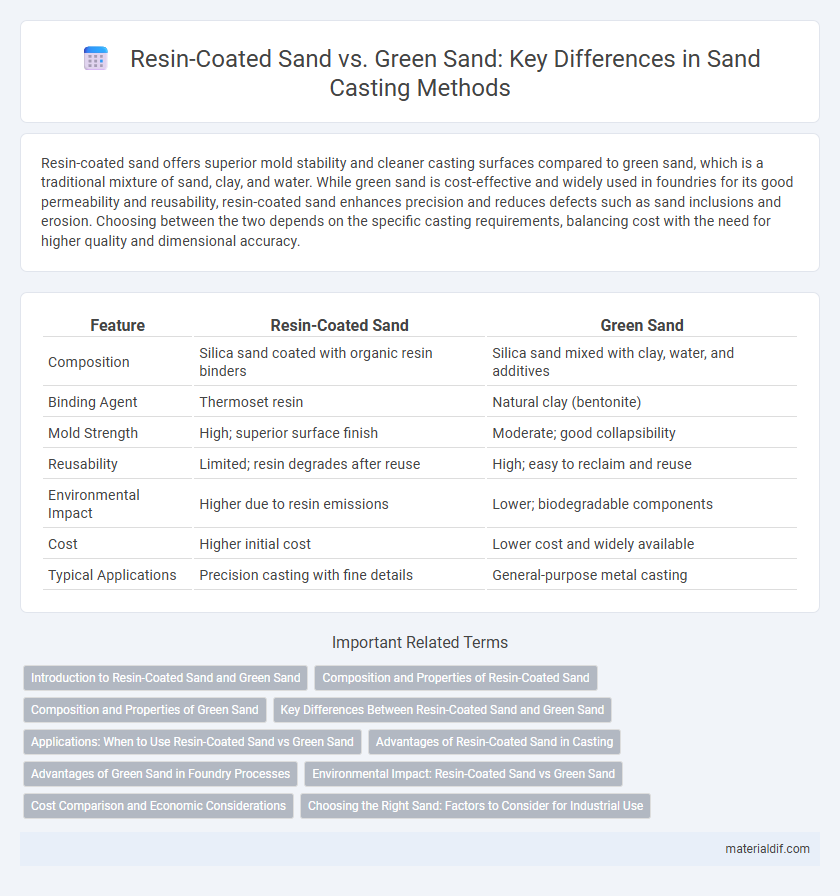

Table of Comparison

| Feature | Resin-Coated Sand | Green Sand |

|---|---|---|

| Composition | Silica sand coated with organic resin binders | Silica sand mixed with clay, water, and additives |

| Binding Agent | Thermoset resin | Natural clay (bentonite) |

| Mold Strength | High; superior surface finish | Moderate; good collapsibility |

| Reusability | Limited; resin degrades after reuse | High; easy to reclaim and reuse |

| Environmental Impact | Higher due to resin emissions | Lower; biodegradable components |

| Cost | Higher initial cost | Lower cost and widely available |

| Typical Applications | Precision casting with fine details | General-purpose metal casting |

Introduction to Resin-Coated Sand and Green Sand

Resin-coated sand consists of natural sand particles bonded with synthetic resins, offering high strength, uniformity, and excellent surface finish for metal casting molds. Green sand combines silica sand with clay and water, providing a reusable, cost-effective molding material with good permeability and thermal stability. Compared to green sand, resin-coated sand delivers superior dimensional accuracy and reduced defects, enhancing casting quality in complex or high-precision applications.

Composition and Properties of Resin-Coated Sand

Resin-coated sand consists of high-quality silica sand particles bonded with synthetic resin, resulting in enhanced strength, uniformity, and improved moldability compared to green sand, which is primarily composed of silica sand mixed with clay, water, and additives. The resin coating in resin-coated sand provides superior permeability, high thermal stability, and better collapsibility, reducing defects in metal casting processes. These properties make resin-coated sand ideal for precision casting and complex mold designs where surface finish and dimensional accuracy are critical.

Composition and Properties of Green Sand

Green sand primarily consists of silica sand, bentonite clay, water, and recyclables, forming a moldable and reusable mixture with excellent cohesiveness. Its composition allows for high permeability and moisture retention, facilitating gas escape during casting and reducing defects. The presence of bentonite clay provides the necessary plasticity and strength, distinguishing green sand from resin-coated sand which uses organic binders for enhanced surface finish and dimensional accuracy.

Key Differences Between Resin-Coated Sand and Green Sand

Resin-coated sand consists of silica sand bonded with synthetic resin, offering higher mold strength and better surface finish compared to green sand, which is a mixture of sand, clay, water, and additives. Green sand is reusable and more cost-effective but has lower dimensional accuracy and creates more casting defects due to moisture content. The key differences lie in mold stability, surface quality, environmental impact, and suitability for complex casting shapes, with resin-coated sand preferred for high-precision and detailed castings.

Applications: When to Use Resin-Coated Sand vs Green Sand

Resin-coated sand is preferred in precision casting applications due to its superior strength, surface finish, and dimensional accuracy, making it ideal for complex metal parts and high-volume production. Green sand is commonly used in general foundry processes for non-critical components and low-cost casting, offering flexibility and ease of reuse in projects where surface finish and detail are less stringent. Selecting resin-coated sand enhances mold stability and reduces defects in intricate designs, whereas green sand suits traditional, cost-efficient applications with quicker turnaround needs.

Advantages of Resin-Coated Sand in Casting

Resin-coated sand offers superior mold strength and higher abrasion resistance compared to green sand, resulting in improved dimensional accuracy and smoother surface finishes in casting. Its enhanced permeability reduces gas defects, increasing casting quality and reducing scrap rates. The consistent grain shape and strength also facilitate easier reclamation and recycling, lowering overall production costs.

Advantages of Green Sand in Foundry Processes

Green sand offers superior moldability and flexibility, allowing for intricate casting details and reduced defects in foundry processes. Its eco-friendly composition, primarily water, silica sand, clay, and organic additives, promotes easier reclamation and reuse compared to resin-coated sand. The cost-effectiveness and wide availability of green sand make it a preferred choice for large-scale and diverse metal casting applications.

Environmental Impact: Resin-Coated Sand vs Green Sand

Resin-coated sand generates less waste and can be recycled multiple times, reducing landfill contributions compared to green sand, which often requires disposal after use. The chemical binders in resin-coated sand can pose environmental risks if not properly managed, whereas green sand is primarily composed of natural materials like clay and sand, resulting in lower toxicity. However, green sand casting produces higher emissions of dust and volatiles during the molding process, impacting air quality more significantly than resin-coated sand.

Cost Comparison and Economic Considerations

Resin-coated sand generally incurs higher initial costs due to the expenses of binder materials and processing, whereas green sand remains more economical because of its abundant availability and simpler handling. Despite the premium price, resin-coated sand offers improved mold strength and surface finish, potentially reducing defects and post-processing costs. Factoring in long-term benefits, industries may find resin-coated sand more cost-effective despite higher upfront investment.

Choosing the Right Sand: Factors to Consider for Industrial Use

Resin-coated sand offers superior mold strength and better surface finish compared to green sand, making it ideal for precision casting in automotive and aerospace industries. Green sand remains cost-effective and environmentally friendly, preferred for large-scale production with moderate detail requirements. Choosing the right sand depends on factors like casting complexity, production volume, cost constraints, and environmental impact.

Resin-coated sand vs Green sand Infographic

materialdif.com

materialdif.com