Masonry sand is coarse and angular, making it ideal for concrete mixes and bricklaying due to its strong binding properties and durability. Plastering sand is finer and smoother, providing a sleek finish that enhances the application of plaster and improving workability on walls. Choosing the right type of sand ensures optimal strength and surface quality in construction projects.

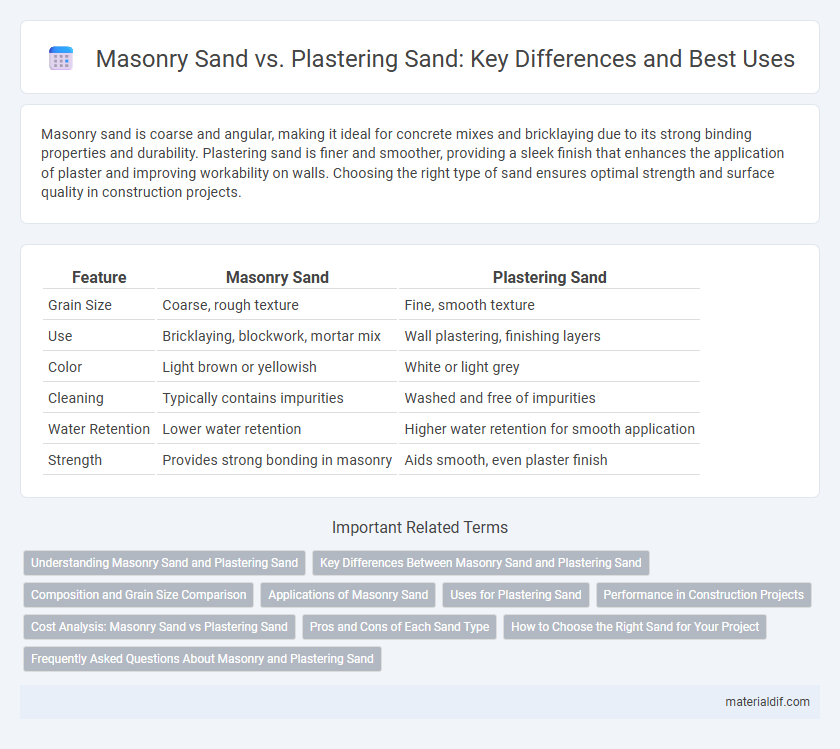

Table of Comparison

| Feature | Masonry Sand | Plastering Sand |

|---|---|---|

| Grain Size | Coarse, rough texture | Fine, smooth texture |

| Use | Bricklaying, blockwork, mortar mix | Wall plastering, finishing layers |

| Color | Light brown or yellowish | White or light grey |

| Cleaning | Typically contains impurities | Washed and free of impurities |

| Water Retention | Lower water retention | Higher water retention for smooth application |

| Strength | Provides strong bonding in masonry | Aids smooth, even plaster finish |

Understanding Masonry Sand and Plastering Sand

Masonry sand features angular grains ideal for concrete blocks, bricks, and mortar, providing strong bonding and durability in construction. Plastering sand consists of fine, smooth particles essential for creating smooth plaster finishes and preventing cracks on walls. Selecting the right sand type enhances structural integrity and surface quality in building projects.

Key Differences Between Masonry Sand and Plastering Sand

Masonry sand features coarse, rounded grains ideal for mixing with cement and creating strong, durable structures like brickwork and concrete blocks. Plastering sand contains finer, smooth particles that provide a softer texture perfect for achieving smooth, crack-resistant plaster finishes on walls. The key difference lies in grain size and texture, influencing their suitability for strength-focused masonry or finish-oriented plastering applications.

Composition and Grain Size Comparison

Masonry sand typically consists of coarse grains ranging from 0.5 to 2 mm, composed mainly of quartz and silica, providing excellent strength for bricklaying and mortar mixing. Plastering sand features finer grains, generally between 0.1 to 0.5 mm, with a higher proportion of silt and clay, resulting in a smoother texture ideal for plaster application and finishing. The grain size and mineral composition differences directly impact the workability and bonding properties in construction tasks.

Applications of Masonry Sand

Masonry sand is primarily used in construction for creating durable mortar mixes that bond bricks, blocks, and stones. Its fine texture enhances workability and strength in masonry projects, making it ideal for laying walls, piers, and other structural elements. Unlike plastering sand, masonry sand supports load-bearing applications due to its consistent grain size and cleanliness.

Uses for Plastering Sand

Plastering sand is finely graded and free from impurities, making it ideal for smooth rendering and plaster coats on walls and ceilings. Its consistent texture ensures better adhesion and a flawless finish in plaster applications. Unlike masonry sand, which is coarser and suited for concrete and bricklaying, plastering sand enhances workability and durability in plaster mixes.

Performance in Construction Projects

Masonry sand features coarse, angular particles that enhance bonding strength and compaction in bricklaying and blockwork, ensuring structural durability. Plastering sand contains finer, smoother particles that provide a consistent finish and superior workability for even and crack-resistant plaster surfaces. Selecting the appropriate sand type directly impacts construction performance, influencing adhesion, surface texture, and long-term stability of masonry and plastering applications.

Cost Analysis: Masonry Sand vs Plastering Sand

Masonry sand typically costs more than plastering sand due to its finer grain size and higher purity, which are essential for structural strength in bricklaying. Plastering sand, being coarser and less processed, is generally cheaper and used primarily for plaster mixes where smooth finish is crucial but tensile strength is less critical. Comparing prices, masonry sand can range from $25 to $50 per ton, whereas plastering sand often falls between $15 to $35 per ton, reflecting differences in processing and application requirements.

Pros and Cons of Each Sand Type

Masonry sand offers a coarse texture ideal for strong bonding in bricklaying and concrete mixing, providing durability but potentially causing rough finishes unsuitable for delicate plastering. Plastering sand has a fine, smooth grain that ensures a sleek, even surface perfect for wall finishes but lacks the strength required for structural applications. Choosing between masonry and plastering sand depends on the balance between surface smoothness and material strength needed for the specific construction task.

How to Choose the Right Sand for Your Project

Masonry sand features coarser grains ideal for mixing with cement to create strong, durable concrete blocks and bricks, while plastering sand has finer particles that provide a smooth finish for wall surfaces. Selecting the right sand depends on the project's requirements: use masonry sand for structural strength and plastering sand for aesthetic, even coatings. Testing sand grain size and cleanliness ensures optimal bonding and longevity in construction tasks.

Frequently Asked Questions About Masonry and Plastering Sand

Masonry sand is coarser and ideal for bricklaying, providing strong adhesion and durability, while plastering sand is finer for smooth wall finishes and easier application. Both sands originate from riverbeds but vary in grain size and cleanliness, affecting their suitability for specific construction tasks. Common questions often address differences in texture, appropriate mixing ratios, and compatibility with cement or lime for optimal results.

Masonry Sand vs Plastering Sand Infographic

materialdif.com

materialdif.com