Green sand, a mixture of sand, clay, water, and additives, is primarily used for creating molds in metal casting due to its excellent moisture retention and flexibility. Core sand, on the other hand, is specially formulated to form the internal cavities or cores of a casting, offering high strength and heat resistance to withstand molten metal. While green sand molds shape the external surfaces, core sand ensures precise internal geometries within the cast metal.

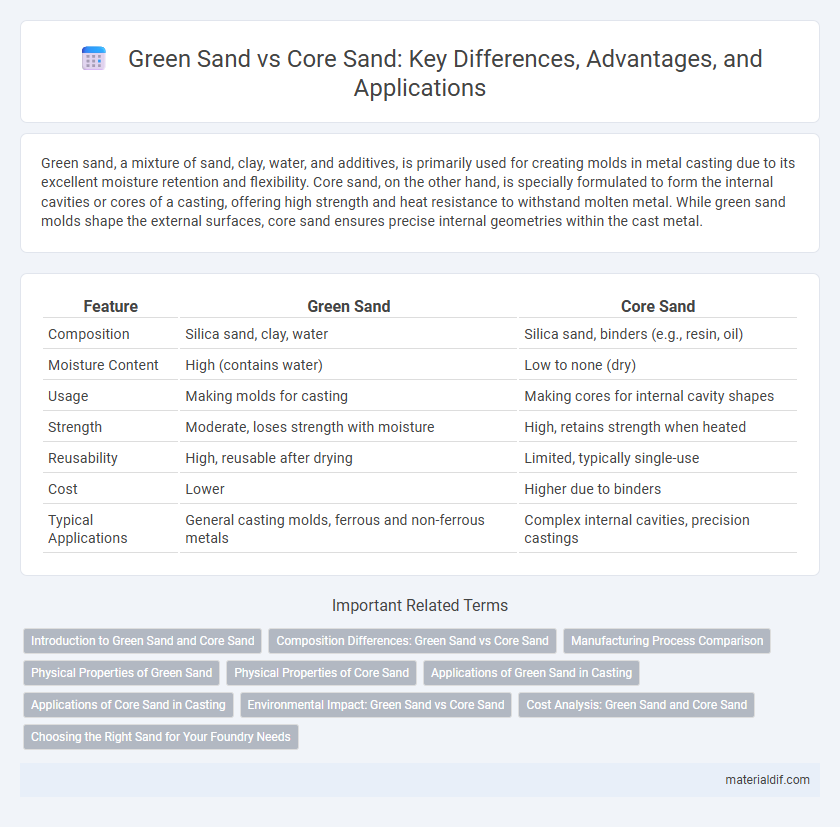

Table of Comparison

| Feature | Green Sand | Core Sand |

|---|---|---|

| Composition | Silica sand, clay, water | Silica sand, binders (e.g., resin, oil) |

| Moisture Content | High (contains water) | Low to none (dry) |

| Usage | Making molds for casting | Making cores for internal cavity shapes |

| Strength | Moderate, loses strength with moisture | High, retains strength when heated |

| Reusability | High, reusable after drying | Limited, typically single-use |

| Cost | Lower | Higher due to binders |

| Typical Applications | General casting molds, ferrous and non-ferrous metals | Complex internal cavities, precision castings |

Introduction to Green Sand and Core Sand

Green sand, composed of silica sand, clay, water, and other additives, is widely used in metal casting due to its high permeability and excellent moldability. Core sand, typically coated with a binder such as resin or oil, is designed to create precise internal cavities in castings and withstand higher temperatures than green sand. Both sands play crucial roles in the foundry process, with green sand forming the main mold structure and core sand forming the detailed internal features.

Composition Differences: Green Sand vs Core Sand

Green sand primarily consists of silica sand, clay, water, and additives providing moisture that enables molding by maintaining cohesion during casting. Core sand, however, is a mixture of silica sand and a binder such as resin or oil, designed to withstand higher temperatures and hold intricate shapes without moisture. The fundamental composition difference lies in green sand's water-based clay binder compared to core sand's chemically bonded binders, optimizing them for different roles in metal casting processes.

Manufacturing Process Comparison

Green sand manufacturing involves mixing silica sand with clay, water, and additives to create a moldable material used in casting, while core sand production incorporates resin binders to form strong, precise cores. The core sand process requires controlled curing methods such as heating or chemical hardening to achieve the necessary strength and dimensional accuracy. Green sand molds are reusable and prepared through simple mixing and molding, whereas core sand involves more complex handling to maintain core structure during metal pouring.

Physical Properties of Green Sand

Green sand exhibits high moisture content, typically around 4-8%, which enhances its plasticity and compactability, crucial for mold making in foundries. Its grain size distribution and clay content contribute to excellent permeability and surface finish, while maintaining sufficient strength to withstand metal casting pressures. Unlike core sand, green sand's physical properties allow for easy reclaiming and reuse, making it economically advantageous for mass production.

Physical Properties of Core Sand

Core sand exhibits exceptional permeability and low clay content, ensuring effective gas escape during casting and minimizing defects. Its high refractoriness withstands extreme temperatures without degrading, essential for maintaining mold integrity. The fine grain size and uniformity of core sand contribute to precise mold shaping and smooth casting surfaces.

Applications of Green Sand in Casting

Green sand, composed of silica sand, clay, water, and additives, is primarily used in molding for metal casting due to its excellent collapsibility and reusability. It is widely applied in automotive engine blocks, pipe fittings, and valve castings where the sand's moisture content aids in bearing the mold's shape and withstanding high temperatures during metal pouring. The ease of molding and cost-effectiveness make green sand ideal for producing complex, large-scale components in foundries.

Applications of Core Sand in Casting

Core sand, used primarily in metal casting, forms the internal cavities of molds, enabling the creation of complex shapes and hollow sections in castings. Its composition, typically a mixture of silica sand, bentonite, and water, ensures high strength and refractoriness to withstand molten metal temperatures. Core sand applications are essential in producing engine blocks, pump housings, and intricate valve components where precise internal geometries are required.

Environmental Impact: Green Sand vs Core Sand

Green sand, composed of natural sand, clay, water, and additives, offers a more environmentally friendly option due to its recyclability and lower emissions during the casting process. Core sand, typically bonded with chemical binders, can create hazardous waste and emissions, leading to greater environmental pollution and disposal challenges. Recycling green sand reduces the need for raw materials, whereas discarded core sand often requires special handling to minimize ecological impact.

Cost Analysis: Green Sand and Core Sand

Green sand typically incurs lower costs due to its reusable nature and the abundance of raw materials like silica sand, clay, and water, making it economically favorable for large-scale casting processes. Core sand, often made from chemically bonded sand mixtures such as resin-coated or oil-bonded sands, demands higher expenses because of specialized binders and additional curing steps, increasing material and processing costs. The overall cost analysis favors green sand for standard castings, while core sand justifies its premium price in applications requiring complex internal geometries or enhanced dimensional accuracy.

Choosing the Right Sand for Your Foundry Needs

Green sand offers excellent moldability and moisture retention, making it ideal for creating complex casting shapes with good surface finish. Core sand, on the other hand, is specially mixed for high strength and heat resistance to form internal cavities and intricate cores inside castings. Selecting the right sand depends on the foundry's requirements for dimensional accuracy, thermal stability, and ease of reclamation in production processes.

Green sand vs Core sand Infographic

materialdif.com

materialdif.com