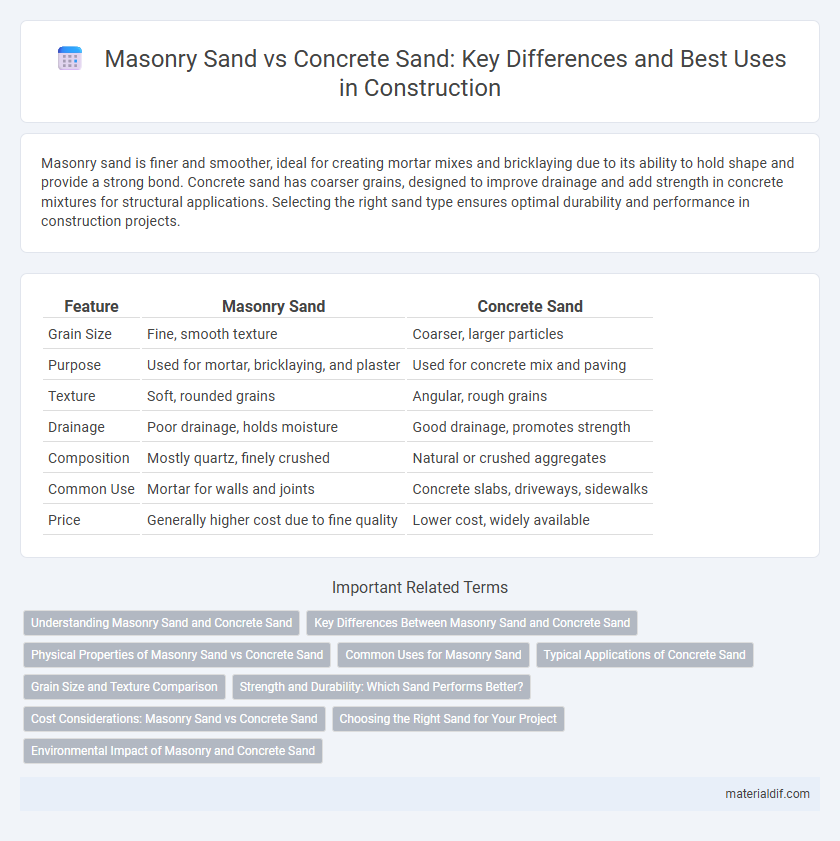

Masonry sand is finer and smoother, ideal for creating mortar mixes and bricklaying due to its ability to hold shape and provide a strong bond. Concrete sand has coarser grains, designed to improve drainage and add strength in concrete mixtures for structural applications. Selecting the right sand type ensures optimal durability and performance in construction projects.

Table of Comparison

| Feature | Masonry Sand | Concrete Sand |

|---|---|---|

| Grain Size | Fine, smooth texture | Coarser, larger particles |

| Purpose | Used for mortar, bricklaying, and plaster | Used for concrete mix and paving |

| Texture | Soft, rounded grains | Angular, rough grains |

| Drainage | Poor drainage, holds moisture | Good drainage, promotes strength |

| Composition | Mostly quartz, finely crushed | Natural or crushed aggregates |

| Common Use | Mortar for walls and joints | Concrete slabs, driveways, sidewalks |

| Price | Generally higher cost due to fine quality | Lower cost, widely available |

Understanding Masonry Sand and Concrete Sand

Masonry sand and concrete sand differ primarily in grain size and texture, with masonry sand featuring fine, smooth grains ideal for mixing mortar in bricklaying and plastering, while concrete sand contains coarser, angular particles designed to provide strength and stability in concrete mixes. Masonry sand's uniformity and softness improve workability and adherence in masonry applications, whereas concrete sand's roughness enhances the bonding and compressive strength required for structural components. Understanding these distinctions is vital for selecting the right sand to ensure durability, finish quality, and performance in construction projects.

Key Differences Between Masonry Sand and Concrete Sand

Masonry sand is finer and smoother, designed for mortar mixtures used in bricklaying and blockwork, while concrete sand is coarser with a rough texture ideal for mixing with cement in concrete slabs and driveways. Masonry sand's grain size typically ranges from 0.1 to 0.3 mm, promoting better adhesion in masonry applications, whereas concrete sand features larger particles around 0.5 to 1 mm for stronger structural integrity. The distinct particle size and texture influence their respective roles in construction, with masonry sand providing workability and precision and concrete sand enhancing compressive strength.

Physical Properties of Masonry Sand vs Concrete Sand

Masonry sand features fine, rounded grains that enhance smoothness and workability, making it ideal for bricklaying and block work, while concrete sand consists of coarser, angular particles that provide superior strength and stability in concrete mixes. The particle size distribution in masonry sand typically ranges from 0.15 to 0.6 mm, promoting ease of spreading and finishing, whereas concrete sand particles vary between 0.6 to 2 mm to improve compaction and load-bearing capacity. Moisture content and grading also differ, with masonry sand often exhibiting lower fines content to prevent shrinkage cracks, contrasted by concrete sand's higher angularity that increases interlocking within the mix.

Common Uses for Masonry Sand

Masonry sand is primarily used in mortar mixes for bricklaying, block laying, and stonework due to its fine texture that allows for strong adhesion and smooth finishes. It is ideal for creating joints and filling gaps between bricks, providing stability and an attractive appearance to masonry projects. Unlike concrete sand, masonry sand is not typically used for structural concrete but excels in applications requiring careful detail and ease of shaping.

Typical Applications of Concrete Sand

Concrete sand is primarily used in the construction industry for creating durable concrete mixes essential for building foundations, sidewalks, and driveways. Its angular texture enhances the strength and stability of concrete structures by improving the bond between cement and aggregates. Common applications also include road base layers, drainage systems, and as a key component in mortar mixes.

Grain Size and Texture Comparison

Masonry sand features finer grains with a smooth, rounded texture, making it ideal for mortar mixes that require better workability and finish. Concrete sand consists of coarser, more angular particles that enhance strength and interlocking in concrete mixes. The grain size of masonry sand typically ranges from 0.1 to 0.5 mm, while concrete sand ranges from 0.5 to 2.0 mm, directly influencing the texture and performance in construction applications.

Strength and Durability: Which Sand Performs Better?

Masonry sand, characterized by its fine texture and smooth grains, enhances the workability and finish of mortar but provides moderate strength and durability. Concrete sand, with coarser particles and angular granules, improves the compressive strength and structural integrity of concrete mixes. For applications demanding higher strength and long-lasting durability, concrete sand generally outperforms masonry sand due to its superior bonding and load-bearing capacity.

Cost Considerations: Masonry Sand vs Concrete Sand

Masonry sand typically costs more per cubic yard compared to concrete sand due to its finer texture and cleaner composition, which makes it ideal for mortar mixes and detailed brickwork. Concrete sand, being coarser and less processed, is generally more affordable and suited for structural applications like concrete slabs and foundations. Budget planning should consider the specific use-case since choosing masonry sand for concrete mixes can increase material expenses without significant performance benefits.

Choosing the Right Sand for Your Project

Masonry sand features fine, smooth grains ideal for mixing mortar to create strong, workable joints, while concrete sand has coarser particles suited for providing structural strength and drainage in concrete mixes. Choosing the right sand depends on the project's requirements: masonry sand enhances bond and finish in bricklaying, whereas concrete sand ensures durability and stability in foundations and slabs. Assessing grain size and texture helps optimize material performance and achieve the desired construction results.

Environmental Impact of Masonry and Concrete Sand

Masonry sand typically undergoes less processing and extraction, resulting in a lower environmental footprint compared to concrete sand, which often requires more intense mining and washing. Concrete sand production generates higher levels of sediment runoff and water contamination risks due to its finer grains and extensive washing processes. Sustainable practices in sourcing and recycling both types of sand can significantly reduce their environmental impacts, promoting eco-friendly construction methods.

Masonry Sand vs Concrete Sand Infographic

materialdif.com

materialdif.com