Sub-angular sand grains have sharp edges and irregular shapes, resulting in higher friction and better interlocking, which enhances soil stability and drainage. Rounded sand grains are smoother and more uniform, promoting easier compaction and better flow but offering less mechanical interlock. Understanding the difference between sub-angular and rounded sand is crucial for applications in construction, landscaping, and filtration systems.

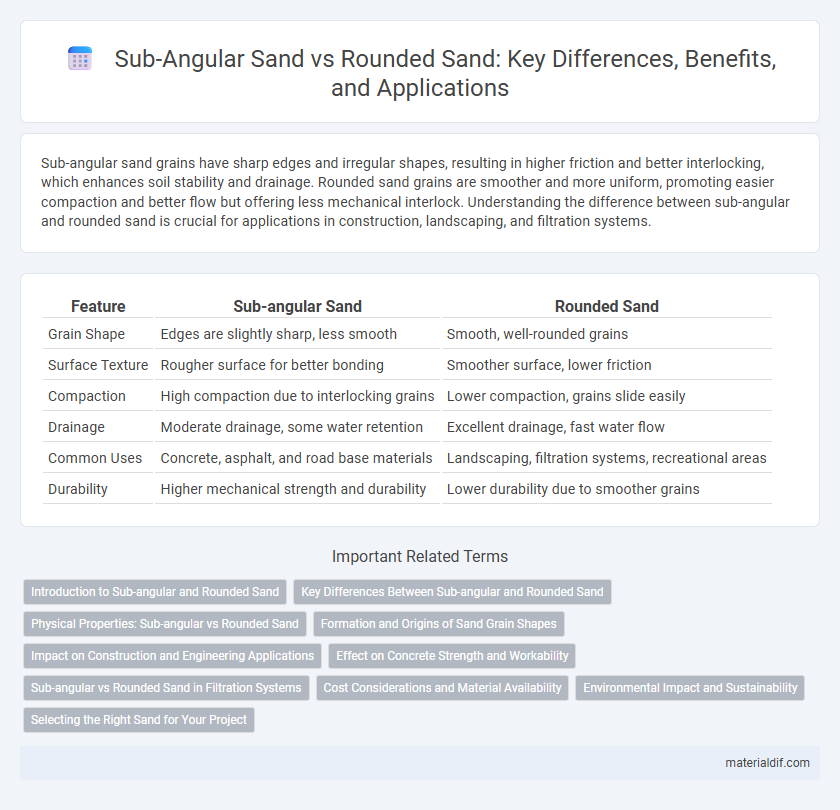

Table of Comparison

| Feature | Sub-angular Sand | Rounded Sand |

|---|---|---|

| Grain Shape | Edges are slightly sharp, less smooth | Smooth, well-rounded grains |

| Surface Texture | Rougher surface for better bonding | Smoother surface, lower friction |

| Compaction | High compaction due to interlocking grains | Lower compaction, grains slide easily |

| Drainage | Moderate drainage, some water retention | Excellent drainage, fast water flow |

| Common Uses | Concrete, asphalt, and road base materials | Landscaping, filtration systems, recreational areas |

| Durability | Higher mechanical strength and durability | Lower durability due to smoother grains |

Introduction to Sub-angular and Rounded Sand

Sub-angular sand particles exhibit edges that are partially worn and less sharp compared to angular sand, resulting from moderate weathering and transport processes. Rounded sand grains show smooth, well-rounded edges caused by extensive abrasion during transportation, indicating longer travel distances or prolonged mechanical weathering. These differences in grain shape significantly influence soil permeability, compaction, and stability in geotechnical applications.

Key Differences Between Sub-angular and Rounded Sand

Sub-angular sand grains possess slightly sharp edges and irregular shapes, resulting in higher friction and better interlocking compared to rounded sand grains, which are smooth and spherical due to prolonged weathering. Rounded sand exhibits lower surface area and reduced friction, enhancing drainage and compaction but offering less stability in construction applications. Understanding these differences is crucial for selecting appropriate sand types in engineering, where sub-angular sand improves structural strength, while rounded sand favors permeability and ease of movement.

Physical Properties: Sub-angular vs Rounded Sand

Sub-angular sand particles exhibit sharper edges and less surface smoothness compared to rounded sand, resulting in higher shear strength and improved interlocking within mixtures. Rounded sand particles possess smoother surfaces and more uniform shapes, leading to better flowability but reduced friction and lower load-bearing capacity. The physical properties of sub-angular sand make it preferable for construction applications requiring stability, while rounded sand is often chosen for aesthetic or drainage purposes.

Formation and Origins of Sand Grain Shapes

Sub-angular sand grains form primarily through limited transport and mechanical weathering, preserving their sharper edges and corners due to minimal abrasion. Rounded sand grains develop from prolonged transportation by wind, water, or ice, where continuous collisions and friction cause the grain edges to smooth and become more spherical. The degree of rounding directly reflects the energy and duration of the sedimentary environment, with river sands often being more rounded than desert or glacial sands.

Impact on Construction and Engineering Applications

Sub-angular sand, characterized by its irregular and angular grains, provides superior interlocking and stability, making it ideal for load-bearing applications in construction such as concrete and road base materials. Rounded sand grains, with their smooth and spherical shapes, offer better workability and drainage but lower shear strength, which may reduce their effectiveness in foundational engineering projects. The choice between sub-angular and rounded sand directly impacts compaction, strength, and durability, influencing the performance and longevity of construction structures.

Effect on Concrete Strength and Workability

Sub-angular sand particles enhance concrete strength due to better interlocking and increased surface area for cement paste adhesion, resulting in denser, more durable mixes. Rounded sand improves workability by reducing internal friction, allowing easier mixing and placement but may slightly reduce overall compressive strength. Balancing sub-angular and rounded sand particles optimizes both the strength and workability of concrete for specific construction needs.

Sub-angular vs Rounded Sand in Filtration Systems

Sub-angular sand particles exhibit sharper edges and less uniformity compared to rounded sand, influencing filtration efficiency in filtration systems. Sub-angular sand enhances mechanical filtration by creating tighter void spaces that trap smaller particulates, while rounded sand offers lower resistance and higher flow rates due to smoother surfaces. Selecting between sub-angular and rounded sand depends on balancing filtration precision and hydraulic conductivity requirements in water treatment applications.

Cost Considerations and Material Availability

Sub-angular sand generally costs less due to its abundant supply in natural deposits, making it a budget-friendly choice for large construction projects. Rounded sand, often sourced from riverbeds or beaches, usually commands a higher price because of its limited availability and additional processing requirements. Material availability heavily influences project budgets, with sub-angular sand preferred in regions where rounded sand is scarce or expensive.

Environmental Impact and Sustainability

Sub-angular sand, with its irregular particle shapes, offers better interlocking and stability in construction applications, reducing the need for additional binding agents that can harm the environment. Rounded sand particles, shaped by natural weathering, often require higher amounts of cement or additives to achieve similar strength, increasing carbon emissions during production. Choosing sub-angular sand promotes sustainability by minimizing material waste and lowering the ecological footprint of building projects.

Selecting the Right Sand for Your Project

Choosing between sub-angular sand and rounded sand depends on the specific requirements of your construction or landscaping project. Sub-angular sand, characterized by its sharp edges and irregular shapes, provides superior compaction and bonding strength, making it ideal for concrete mixes and structural applications. Rounded sand, with its smooth and spherical grains, offers better drainage and workability, suitable for plastering and filtration systems.

Sub-angular Sand vs Rounded Sand Infographic

materialdif.com

materialdif.com