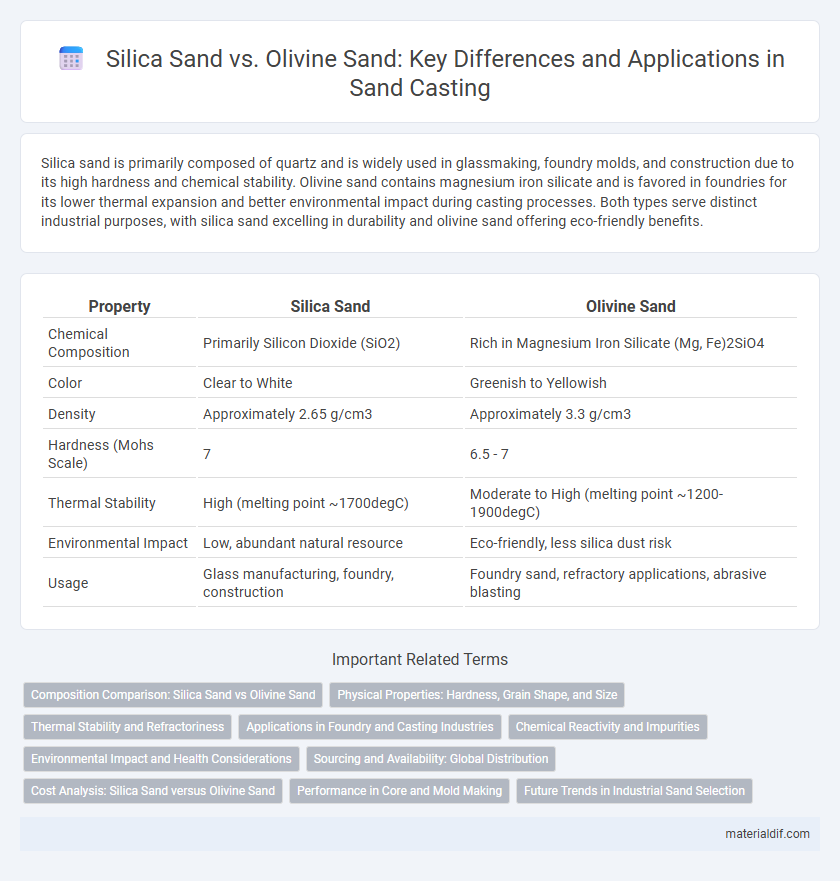

Silica sand is primarily composed of quartz and is widely used in glassmaking, foundry molds, and construction due to its high hardness and chemical stability. Olivine sand contains magnesium iron silicate and is favored in foundries for its lower thermal expansion and better environmental impact during casting processes. Both types serve distinct industrial purposes, with silica sand excelling in durability and olivine sand offering eco-friendly benefits.

Table of Comparison

| Property | Silica Sand | Olivine Sand |

|---|---|---|

| Chemical Composition | Primarily Silicon Dioxide (SiO2) | Rich in Magnesium Iron Silicate (Mg, Fe)2SiO4 |

| Color | Clear to White | Greenish to Yellowish |

| Density | Approximately 2.65 g/cm3 | Approximately 3.3 g/cm3 |

| Hardness (Mohs Scale) | 7 | 6.5 - 7 |

| Thermal Stability | High (melting point ~1700degC) | Moderate to High (melting point ~1200-1900degC) |

| Environmental Impact | Low, abundant natural resource | Eco-friendly, less silica dust risk |

| Usage | Glass manufacturing, foundry, construction | Foundry sand, refractory applications, abrasive blasting |

Composition Comparison: Silica Sand vs Olivine Sand

Silica sand primarily consists of silicon dioxide (SiO2) with a high purity level, making it ideal for glassmaking and industrial applications requiring chemical stability. Olivine sand is rich in magnesium iron silicate ((Mg, Fe)2SiO4), offering greater density and higher melting points, suitable for foundry use and refractory materials. The compositional differences influence their physical properties, with silica sand exhibiting higher hardness and olivine sand providing enhanced thermal resistance.

Physical Properties: Hardness, Grain Shape, and Size

Silica sand features a hardness of 7 on the Mohs scale, with angular to sub-angular grain shapes and a grain size typically ranging from 0.02 to 2 millimeters. Olivine sand exhibits a slightly lower hardness of 6.5 to 7, with more rounded grain shapes and a grain size commonly between 0.1 and 1.5 millimeters. The differences in hardness and grain morphology influence their suitability for various industrial applications, such as foundry casting and abrasive blasting.

Thermal Stability and Refractoriness

Silica sand exhibits high thermal stability with a melting point around 1713degC, making it suitable for applications requiring strong refractoriness. Olivine sand offers enhanced thermal shock resistance and maintains stability at temperatures up to approximately 1890degC, which is beneficial in foundry and refractory processes. The choice between silica and olivine sand depends on the specific thermal demands and the need for resistance to thermal degradation during high-temperature operations.

Applications in Foundry and Casting Industries

Silica sand is widely used in foundry and casting industries due to its high melting point and chemical stability, making it ideal for mold and core production in metal casting. Olivine sand is preferred for applications requiring faster cooling and less thermal expansion, improving casting accuracy and surface finish, especially for non-ferrous metals. Both sands contribute to precise mold formation, but silica's widespread availability and cost-effectiveness make it dominant, while olivine is valuable for specialized or environmentally sensitive foundry processes.

Chemical Reactivity and Impurities

Silica sand primarily consists of quartz (SiO2) with low chemical reactivity but can contain iron oxide impurities that may affect its purity and performance in industrial applications. Olivine sand, composed mainly of magnesium iron silicate ((Mg,Fe)2SiO4), exhibits higher chemical reactivity due to its inherent metal content, making it suitable for applications requiring rapid energy transfer or corrosion resistance. The impurity profile in olivine, often including magnesium and iron oxides, enhances its chemical activity compared to the more inert silica sand.

Environmental Impact and Health Considerations

Silica sand extraction often leads to significant environmental disruption, including habitat destruction and increased dust emissions containing crystalline silica, a known respiratory hazard causing silicosis. In contrast, olivine sand mining tends to have a lower environmental footprint and releases fewer harmful particulates, making it a safer alternative for workers' respiratory health. The reduced health risks and environmental benefits of olivine sand make it preferable for industries focused on sustainability and occupational safety.

Sourcing and Availability: Global Distribution

Silica sand is globally abundant, with major deposits found in the United States, Australia, Brazil, and India, making it readily accessible for industrial use. Olivine sand, sourced primarily from volcanic regions such as Norway, New Zealand, and the U.S. state of Hawaii, has a more limited yet strategically important distribution linked to unique geological formations. The widespread availability of silica sand contrasts with olivine sand's localized sourcing, impacting supply chain dynamics and application suitability.

Cost Analysis: Silica Sand versus Olivine Sand

Silica sand is generally more cost-effective than olivine sand due to its abundant availability and lower extraction expenses, making it a preferred choice in industries like glass manufacturing and foundry casting. Olivine sand, while pricier, offers superior thermal resistance and environmental benefits such as lower emissions, justifying its higher cost for specialized applications like refractory linings and metalcasting. Overall, the cost analysis favors silica sand for budget-sensitive projects, whereas olivine sand's premium pricing aligns with performance-driven requirements.

Performance in Core and Mold Making

Silica sand offers high thermal stability and fine particle size, making it ideal for precision core and mold making in foundries, but it can lead to higher binder consumption and potential defects due to its smooth surface. Olivine sand provides excellent refractoriness and better thermal conductivity, reducing casting defects and improving surface finish while being more environmentally friendly due to lower crystalline silica content. Performance comparison shows olivine sand excels in molding processes requiring higher strength and durability but silica sand remains preferred for applications demanding finer detail and dimensional accuracy.

Future Trends in Industrial Sand Selection

Silica sand remains dominant in industrial applications due to its high purity and consistent grain size, but increasing environmental regulations and sustainability concerns drive the shift toward olivine sand as a greener alternative. Olivine sand offers superior abrasion resistance and lower CO2 emissions during processing, making it attractive for foundries and hydraulic fracturing industries. Advances in mining technology and resource availability will further influence the future balance between silica and olivine sand in industrial sand selection.

Silica sand vs Olivine sand Infographic

materialdif.com

materialdif.com