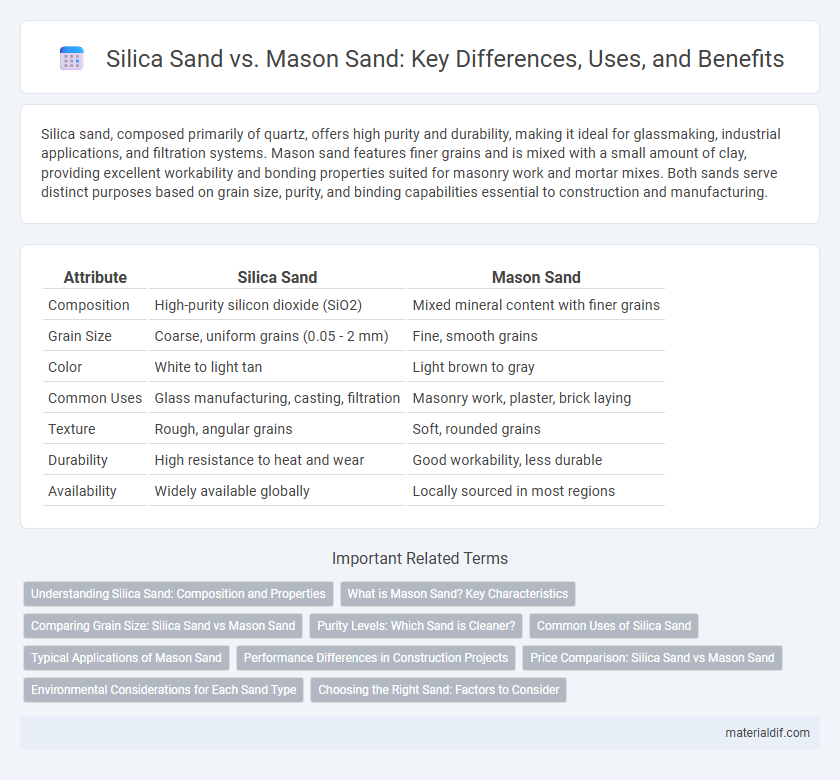

Silica sand, composed primarily of quartz, offers high purity and durability, making it ideal for glassmaking, industrial applications, and filtration systems. Mason sand features finer grains and is mixed with a small amount of clay, providing excellent workability and bonding properties suited for masonry work and mortar mixes. Both sands serve distinct purposes based on grain size, purity, and binding capabilities essential to construction and manufacturing.

Table of Comparison

| Attribute | Silica Sand | Mason Sand |

|---|---|---|

| Composition | High-purity silicon dioxide (SiO2) | Mixed mineral content with finer grains |

| Grain Size | Coarse, uniform grains (0.05 - 2 mm) | Fine, smooth grains |

| Color | White to light tan | Light brown to gray |

| Common Uses | Glass manufacturing, casting, filtration | Masonry work, plaster, brick laying |

| Texture | Rough, angular grains | Soft, rounded grains |

| Durability | High resistance to heat and wear | Good workability, less durable |

| Availability | Widely available globally | Locally sourced in most regions |

Understanding Silica Sand: Composition and Properties

Silica sand primarily consists of quartz (SiO2) particles, which are angular and have a high silica content typically above 95%, making it highly durable and chemically inert. Mason sand, often composed of finer grains with more impurities and lower silica content, is softer and smoother, suited for masonry and plastering applications. The high purity and hardness of silica sand contribute to its widespread use in industrial processes like glassmaking and foundry casting, while mason sand's texture enhances workability in construction.

What is Mason Sand? Key Characteristics

Mason sand is a finely ground, clean, and well-graded sand primarily used for masonry work, plastering, and concrete finishing. Its key characteristics include a smooth texture, angular grains that provide excellent bonding properties, and minimal clay or silt content to ensure durability and ease of mixing. Compared to silica sand, mason sand has finer particles and is specifically tailored for construction applications requiring strong adhesion and a polished surface.

Comparing Grain Size: Silica Sand vs Mason Sand

Silica sand typically features uniform, coarse grains ranging from 0.02 to 2 millimeters in diameter, making it ideal for industrial uses like glassmaking and filtration. Mason sand, in contrast, has finer, more rounded grains usually measured between 0.1 and 0.5 millimeters, which improves workability and compaction in masonry and concrete applications. The distinct grain size of silica sand provides greater strength and durability, while mason sand's finer texture enhances smooth finishes and ease of mixing.

Purity Levels: Which Sand is Cleaner?

Silica sand contains a high percentage of silicon dioxide (SiO2), often exceeding 95%, making it much purer than mason sand, which typically includes various minerals and impurities like clay and silt. The high purity levels of silica sand result in a cleaner, more uniform material ideal for industrial applications such as glassmaking and filtration. In contrast, mason sand's lower purity makes it better suited for masonry work where binding strength and texture are prioritized over cleanliness.

Common Uses of Silica Sand

Silica sand is predominantly used in industrial applications such as glass manufacturing, foundry casting, and hydraulic fracturing due to its high purity and uniform grain size. Its chemical inertness and durability make it ideal for use in water filtration systems and concrete production, enhancing structural integrity. Mason sand, in contrast, is mainly utilized for masonry work and landscaping because of its finer texture and softer composition.

Typical Applications of Mason Sand

Mason sand is commonly used in masonry work, providing a smooth finish for mortar and concrete applications due to its fine texture and uniform grain size. It is ideal for bricklaying, plastering, and stucco work where a clean, workable consistency is essential for strong bonding. Unlike coarser silica sand, mason sand enhances the aesthetic appeal and durability of masonry structures by reducing voids and improving compaction.

Performance Differences in Construction Projects

Silica sand exhibits higher purity with a greater percentage of silicon dioxide (SiO2), enhancing strength and durability in concrete mixes, making it ideal for structural applications. Mason sand has finer grains and rounded particles, providing better workability and smoothness for mortar and plaster but lower compressive strength compared to silica sand. Projects requiring high-performance concrete benefit from silica sand's superior bonding properties, whereas masonry work prioritizes mason sand's ease of application and finish quality.

Price Comparison: Silica Sand vs Mason Sand

Silica sand typically costs more than mason sand due to its higher purity and specialized industrial uses, with prices ranging from $30 to $60 per ton compared to mason sand's $20 to $40 per ton. The cost difference reflects silica sand's demand in manufacturing glass, foundry molds, and hydraulic fracturing, whereas mason sand is primarily used for mortar and concrete work. Variations in regional availability and quality grades also influence the pricing between silica sand and mason sand.

Environmental Considerations for Each Sand Type

Silica sand, primarily composed of quartz, poses environmental concerns due to its mining process, which can lead to habitat disruption and respiratory health risks from fine silica dust. Mason sand, often sourced from natural riverbeds, generally has a lower concentration of crystalline silica, reducing respiratory hazards but potentially causing greater ecological impact through waterway disturbances. Choosing between silica and mason sand requires balancing occupational safety and ecosystem preservation depending on project requirements.

Choosing the Right Sand: Factors to Consider

Silica sand, composed primarily of quartz, offers high purity and consistent grain size, making it ideal for glassmaking, industrial uses, and construction requiring durability. Mason sand, characterized by its fine, smooth texture and natural color variations, is preferred for masonry work, bricklaying, and plastering due to its excellent workability and bonding properties. When choosing between silica sand and mason sand, consider factors such as grain size, purity, application requirements, and environmental conditions to ensure optimal strength, finish, and performance in the intended project.

Silica sand vs Mason sand Infographic

materialdif.com

materialdif.com