Sharp sand features coarse, angular grains that provide excellent drainage and stability, making it ideal for concrete mixes and paving. Soft sand has finer, smoother particles that are better suited for plastering and masonry work, offering a softer texture and easier workability. Choosing between sharp and soft sand depends on the construction purpose, ensuring optimal strength and finish quality.

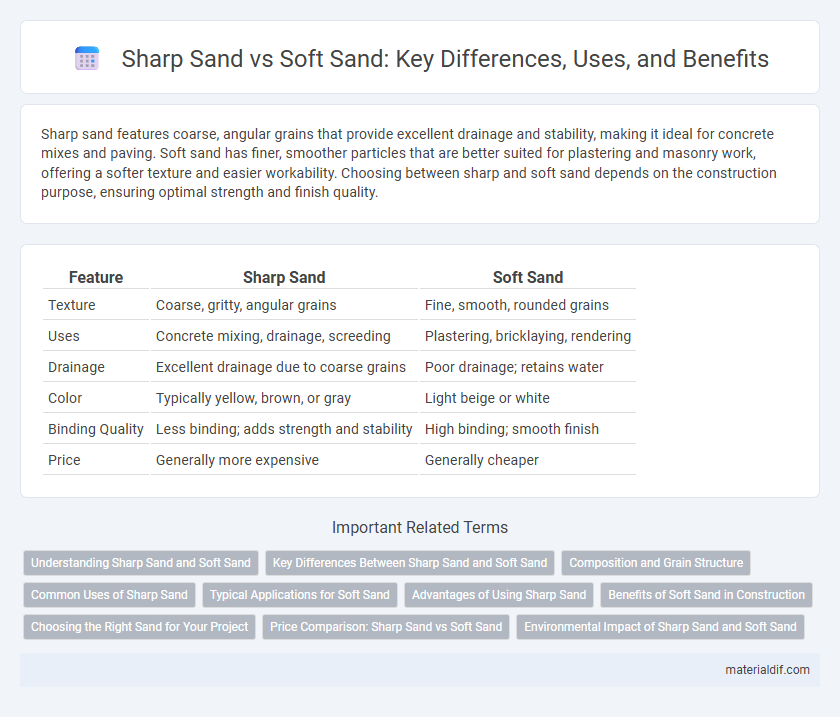

Table of Comparison

| Feature | Sharp Sand | Soft Sand |

|---|---|---|

| Texture | Coarse, gritty, angular grains | Fine, smooth, rounded grains |

| Uses | Concrete mixing, drainage, screeding | Plastering, bricklaying, rendering |

| Drainage | Excellent drainage due to coarse grains | Poor drainage; retains water |

| Color | Typically yellow, brown, or gray | Light beige or white |

| Binding Quality | Less binding; adds strength and stability | High binding; smooth finish |

| Price | Generally more expensive | Generally cheaper |

Understanding Sharp Sand and Soft Sand

Sharp sand, also known as coarse sand, features angular grains that provide excellent drainage and strong binding properties, making it ideal for concrete mixes and paving. Soft sand, characterized by its fine, smooth particles, is commonly used in plastering and mortar due to its workability and smooth finish. Selecting the right sand type depends on construction needs, with sharp sand offering strength and durability, while soft sand ensures ease of application and surface smoothness.

Key Differences Between Sharp Sand and Soft Sand

Sharp sand features coarse, angular grains ideal for concrete and paving due to its strong bonding properties, whereas soft sand consists of finer, smoother particles suited for plastering and rendering to achieve a smooth finish. Sharp sand ensures durability and structural integrity in construction, while soft sand enhances workability and surface smoothness. Understanding these distinctions helps optimize material choice for specific building applications.

Composition and Grain Structure

Sharp sand features coarse, angular grains composed mainly of quartz and silica, providing excellent drainage and strong bonding in construction applications. Soft sand contains finer, rounded grains with a higher clay and silt content, making it ideal for plastering due to its smooth texture and workability. The distinct grain structure and mineral composition of sharp and soft sand determine their suitability for different building purposes.

Common Uses of Sharp Sand

Sharp sand, also known as coarse sand or grit sand, is commonly used in construction for creating strong concrete mixes and durable mortar due to its angular grains that enhance bonding strength. It is ideal for laying paving slabs, blocks, and bricks, providing excellent drainage properties and preventing cracking in solid surfaces. Sharp sand is preferred in concrete flooring, screeding, and for mixing with cement in heavy-duty applications where high structural integrity is required.

Typical Applications for Soft Sand

Soft sand is primarily used in plastering work and bricklaying due to its fine grain size and smooth texture, which ensures a better finish and easier workability. It is ideal for making mortar that requires a smooth surface and strong adhesion, commonly applied in internal wall rendering and pointed brick joints. Typical applications also include mixing with cement for rendering and internal plaster where a soft, workable consistency is essential.

Advantages of Using Sharp Sand

Sharp sand offers superior drainage and strength compared to soft sand, making it ideal for concrete mixing and paving applications. Its angular grains create better interlocking, enhancing structural stability and reducing the risk of cracking. Using sharp sand improves the durability and longevity of construction projects, especially in heavy-duty environments.

Benefits of Soft Sand in Construction

Soft sand enhances construction quality by providing better workability and smoother finishes in plastering and rendering applications. Its fine texture increases bonding strength with cement, resulting in more durable and crack-resistant surfaces. Using soft sand reduces the risk of voids and improves the overall aesthetic of masonry and concrete structures.

Choosing the Right Sand for Your Project

Sharp sand, characterized by its coarse texture and angular grains, provides excellent drainage and strength, making it ideal for concrete mixes, paving, and rendering. Soft sand, with its fine, smooth particles, enhances workability and finish quality, suitable for plastering and bricklaying where a softer finish is desired. Selecting the right type depends on the specific project requirements, soil stability, and desired structural durability.

Price Comparison: Sharp Sand vs Soft Sand

Sharp sand typically costs more than soft sand due to its coarser texture and suitability for concrete and construction purposes. Soft sand, favored for plastering and bricklaying, is generally more affordable because of its finer grains and ease of extraction. Price variations depend on local availability, with sharp sand averaging around $40 to $60 per cubic yard and soft sand ranging from $30 to $50 per cubic yard.

Environmental Impact of Sharp Sand and Soft Sand

Sharp sand, commonly used in construction and concrete production, has a higher environmental impact due to the intensive quarrying processes that disrupt ecosystems and increase carbon emissions. Soft sand, often sourced from riverbeds or coastal areas, can lead to erosion and habitat loss, affecting aquatic life and water quality. Sustainable sand extraction practices and regulations are essential to minimize these environmental damages for both types of sand.

Sharp sand vs Soft sand Infographic

materialdif.com

materialdif.com