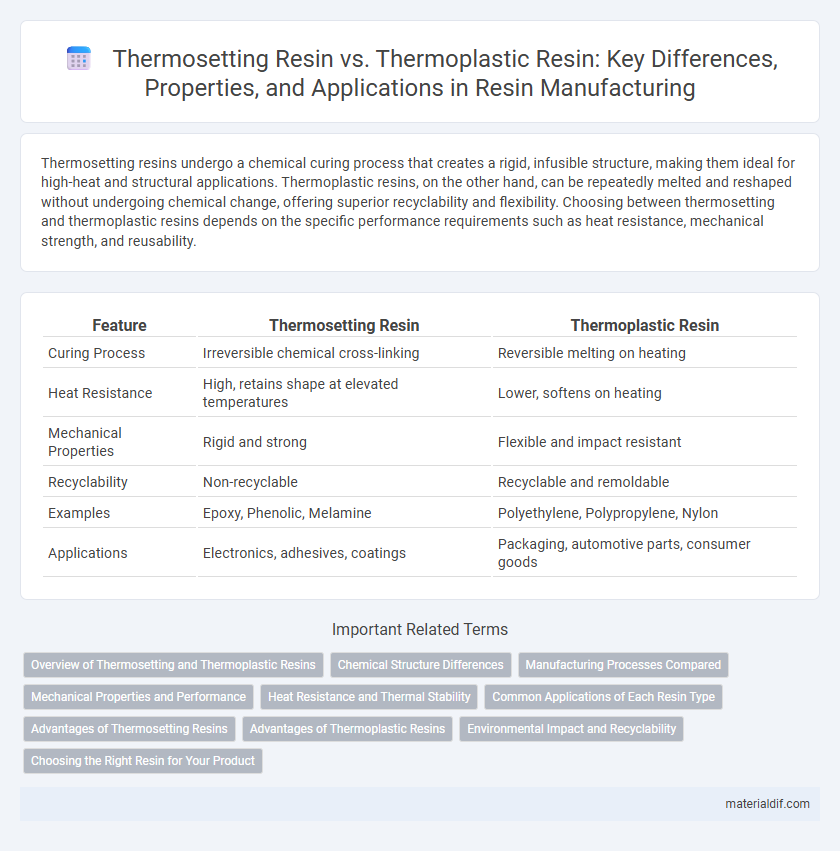

Thermosetting resins undergo a chemical curing process that creates a rigid, infusible structure, making them ideal for high-heat and structural applications. Thermoplastic resins, on the other hand, can be repeatedly melted and reshaped without undergoing chemical change, offering superior recyclability and flexibility. Choosing between thermosetting and thermoplastic resins depends on the specific performance requirements such as heat resistance, mechanical strength, and reusability.

Table of Comparison

| Feature | Thermosetting Resin | Thermoplastic Resin |

|---|---|---|

| Curing Process | Irreversible chemical cross-linking | Reversible melting on heating |

| Heat Resistance | High, retains shape at elevated temperatures | Lower, softens on heating |

| Mechanical Properties | Rigid and strong | Flexible and impact resistant |

| Recyclability | Non-recyclable | Recyclable and remoldable |

| Examples | Epoxy, Phenolic, Melamine | Polyethylene, Polypropylene, Nylon |

| Applications | Electronics, adhesives, coatings | Packaging, automotive parts, consumer goods |

Overview of Thermosetting and Thermoplastic Resins

Thermosetting resins, such as epoxy, phenolic, and melamine, undergo irreversible chemical curing, creating a rigid, heat-resistant structure ideal for high-strength applications. Thermoplastic resins, including polyethylene, polypropylene, and polystyrene, soften when heated and solidify upon cooling, enabling recyclability and ease of molding. The key distinction lies in the permanent cross-linked network of thermosetting resins versus the reversible physical changes in thermoplastics.

Chemical Structure Differences

Thermosetting resins have a highly cross-linked chemical structure formed through irreversible curing processes, creating a rigid three-dimensional network that provides superior heat resistance and mechanical strength. In contrast, thermoplastic resins consist of linear or branched polymer chains without cross-linking, allowing them to be melted and reshaped multiple times due to weaker intermolecular forces. The fundamental difference lies in the presence of covalent cross-links in thermosetting resins versus the absence of such bonds in thermoplastic resins, resulting in distinct thermal and mechanical properties.

Manufacturing Processes Compared

Thermosetting resins undergo irreversible curing through heat or chemical reactions, forming a rigid, cross-linked structure ideal for high-strength, heat-resistant applications. Thermoplastic resins soften when heated and harden upon cooling, allowing for repeated melting and reshaping, which facilitates easier manufacturing processes such as extrusion, injection molding, and thermoforming. Manufacturing thermosets typically requires longer curing times and mold tooling to achieve final properties, while thermoplastics enable faster production cycles and recyclability due to their reversible melting behavior.

Mechanical Properties and Performance

Thermosetting resins exhibit superior mechanical properties such as higher tensile strength, rigidity, and heat resistance compared to thermoplastic resins, making them ideal for applications requiring dimensional stability under stress. Thermoplastic resins offer greater flexibility, impact resistance, and ease of reshaping, enabling repeated thermal processing without significant degradation. The choice between thermosetting and thermoplastic resins depends on performance demands like load-bearing capacity, thermal stability, and recyclability in specific engineering applications.

Heat Resistance and Thermal Stability

Thermosetting resins exhibit superior heat resistance and thermal stability compared to thermoplastic resins, maintaining structural integrity at temperatures above 200degC due to their cross-linked polymer chains. Thermoplastic resins soften and melt when exposed to high heat, typically above 100-250degC, limiting their use in high-temperature applications. The irreversible curing process of thermosetting resins contributes to their excellent thermal stability, making them ideal for automotive, aerospace, and electrical insulation components.

Common Applications of Each Resin Type

Thermosetting resins are widely used in applications requiring high thermal stability and chemical resistance, such as in electrical insulation, aerospace components, and adhesives. Thermoplastic resins find common usage in automotive parts, packaging, and consumer goods due to their ability to be reshaped and recycled. Each resin type's unique molecular structure dictates its suitability for specific industries and performance requirements.

Advantages of Thermosetting Resins

Thermosetting resins offer superior chemical resistance, mechanical strength, and thermal stability compared to thermoplastic resins, making them ideal for high-performance applications such as aerospace and electronics. Their irreversible curing process creates a robust, cross-linked structure that maintains integrity under heat and pressure. This durability ensures long-term reliability and resistance to deformation in demanding environments.

Advantages of Thermoplastic Resins

Thermoplastic resins offer exceptional versatility due to their ability to be repeatedly melted and reshaped without significant chemical alteration, enabling efficient recycling and cost savings in manufacturing. They exhibit superior impact resistance and flexibility compared to thermosetting resins, making them ideal for applications requiring durability and repeated stress. The ease of processing thermoplastic resins also allows for faster production cycles and complex design integration, enhancing overall material performance in automotive, packaging, and consumer electronics industries.

Environmental Impact and Recyclability

Thermosetting resins form irreversible chemical bonds upon curing, making them difficult to recycle and often leading to landfill disposal, which contributes to environmental concerns. Thermoplastic resins, in contrast, can be melted and reshaped multiple times, offering superior recyclability and reducing waste accumulation. The choice between these resins significantly influences environmental sustainability, with thermoplastics generally favored for their lower ecological footprint and enhanced circular economy potential.

Choosing the Right Resin for Your Product

Thermosetting resin offers superior heat resistance and structural stability, making it ideal for applications requiring durable, high-performance materials such as automotive parts and electronics. Thermoplastic resin provides flexibility and recyclability, suitable for products needing repeated shaping and molding like packaging and consumer goods. Selecting the right resin depends on factors like mechanical strength, thermal properties, and end-use environment to ensure optimal product performance and longevity.

Thermosetting Resin vs Thermoplastic Resin Infographic

materialdif.com

materialdif.com