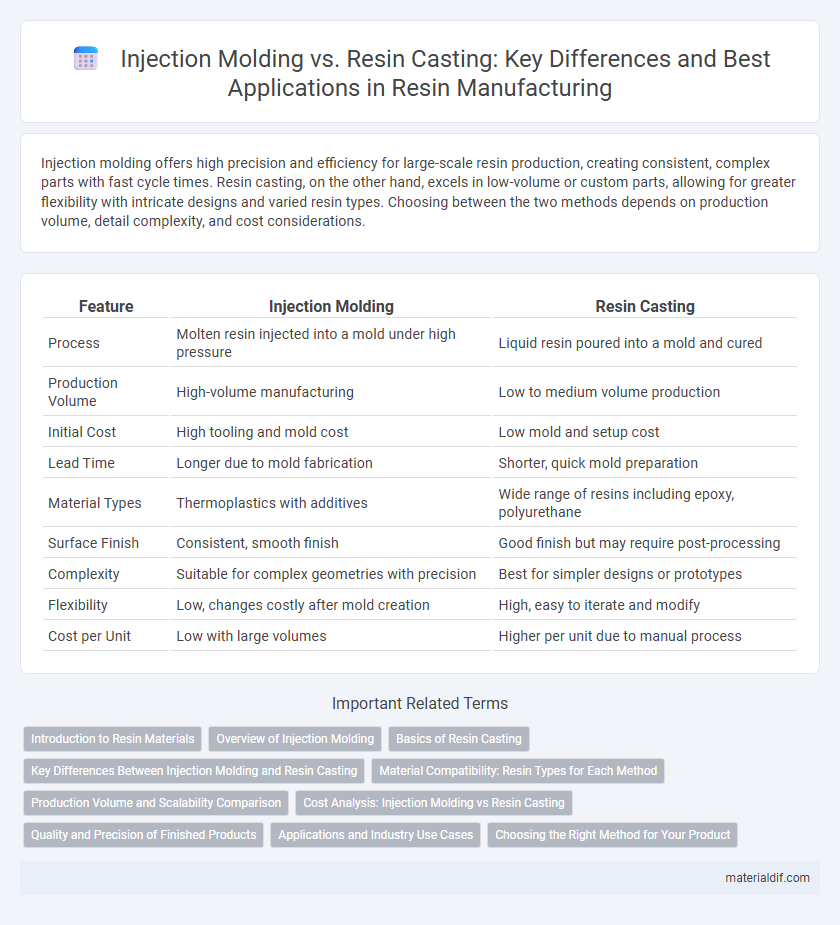

Injection molding offers high precision and efficiency for large-scale resin production, creating consistent, complex parts with fast cycle times. Resin casting, on the other hand, excels in low-volume or custom parts, allowing for greater flexibility with intricate designs and varied resin types. Choosing between the two methods depends on production volume, detail complexity, and cost considerations.

Table of Comparison

| Feature | Injection Molding | Resin Casting |

|---|---|---|

| Process | Molten resin injected into a mold under high pressure | Liquid resin poured into a mold and cured |

| Production Volume | High-volume manufacturing | Low to medium volume production |

| Initial Cost | High tooling and mold cost | Low mold and setup cost |

| Lead Time | Longer due to mold fabrication | Shorter, quick mold preparation |

| Material Types | Thermoplastics with additives | Wide range of resins including epoxy, polyurethane |

| Surface Finish | Consistent, smooth finish | Good finish but may require post-processing |

| Complexity | Suitable for complex geometries with precision | Best for simpler designs or prototypes |

| Flexibility | Low, changes costly after mold creation | High, easy to iterate and modify |

| Cost per Unit | Low with large volumes | Higher per unit due to manual process |

Introduction to Resin Materials

Resin materials used in injection molding typically include thermoplastics like ABS, polycarbonate, and nylon, offering high precision and durability for mass production. Resin casting favors thermosetting resins such as polyurethane, epoxy, and silicone, providing flexibility and ease for prototyping and small batch fabrication. Understanding the chemical properties and curing processes of these resins is essential for selecting the right method based on application requirements and production volume.

Overview of Injection Molding

Injection molding is a manufacturing process that involves injecting molten resin into a precision-engineered steel mold, allowing for high-volume production of consistent and complex plastic parts. This method offers rapid cycle times, superior surface finish, and excellent dimensional accuracy, making it ideal for mass production in automotive, medical, and consumer electronics industries. The upfront tooling cost is higher compared to resin casting, but injection molding delivers greater repeatability and lower per-unit cost at scale.

Basics of Resin Casting

Resin casting involves pouring liquid resin into a mold where it hardens into a solid form, enabling the creation of highly detailed and complex shapes with minimal tooling costs. This process is ideal for small production runs and prototyping, as it allows for easy customization and rapid iteration without the need for expensive injection molding machinery. Resin casting typically uses silicone molds that capture fine surface details and offer flexibility in producing intricate designs compared to the rigid metal molds in injection molding.

Key Differences Between Injection Molding and Resin Casting

Injection molding involves forcing molten resin into a mold under high pressure, enabling rapid production of complex, high-volume parts with excellent dimensional accuracy. Resin casting uses liquid resin poured into a mold and cured at room temperature or with mild heat, ideal for low-volume, detailed prototypes or small batches with flexible material options. Key differences include injection molding's high upfront tooling costs and faster cycle times versus resin casting's lower setup costs and slower, artisanal process suited for customization.

Material Compatibility: Resin Types for Each Method

Injection molding typically uses thermoplastic resins such as ABS, polypropylene, and nylon, which offer excellent flow properties and high durability suitable for mass production. Resin casting is compatible with thermosetting resins like epoxy, polyurethane, and silicone, which allow for intricate detail and are ideal for low-volume or prototype parts. The choice between these methods depends on the resin's chemical composition, curing process, and desired mechanical properties of the final product.

Production Volume and Scalability Comparison

Injection molding excels in high production volumes due to its automated process and durable molds, enabling consistent part replication with minimal cycle time. Resin casting offers flexibility and lower setup costs, making it ideal for small-batch or prototype production but struggles to scale efficiently beyond low to medium volumes. Scalability in injection molding surpasses resin casting as the cost per unit decreases dramatically with volume increases, while resin casting's manual nature limits its efficiency for mass production.

Cost Analysis: Injection Molding vs Resin Casting

Injection molding involves high initial costs due to expensive mold fabrication but offers significantly lower per-unit expenses for large production volumes, making it ideal for mass manufacturing. Resin casting has minimal upfront expenditures with simple mold creation, which suits low-volume runs or prototypes but results in higher per-part costs when scaled. Evaluating cost efficiency depends on the production quantity, where injection molding is more economical beyond a certain volume threshold compared to resin casting.

Quality and Precision of Finished Products

Injection molding offers superior quality and precision through consistent cavity filling and controlled cooling, resulting in uniform resin parts with tight tolerances and smooth surface finishes. Resin casting, while versatile for low-volume production and intricate designs, typically yields parts with more variability in surface texture and dimensional accuracy due to manual mold-making and curing processes. For applications demanding high repeatability and exact specifications, injection molding is the preferred method to achieve optimal resin product quality and precision.

Applications and Industry Use Cases

Injection molding excels in high-volume production of precise, durable resin parts used extensively in automotive, electronics, and consumer goods industries. Resin casting offers flexibility for low-volume, complex prototypes and custom parts, favored in aerospace, jewelry, and art applications. Both methods cater to distinct industrial needs, with injection molding driving mass production efficiency and resin casting supporting specialized, intricate designs.

Choosing the Right Method for Your Product

Injection molding offers high precision and scalability, ideal for large production runs requiring consistent quality and intricate details. Resin casting provides greater flexibility and lower setup costs, making it suitable for small batches, prototypes, and custom designs. Evaluating production volume, budget constraints, and desired material properties is essential for selecting the most efficient manufacturing method for your resin product.

Injection Molding vs Resin Casting Infographic

materialdif.com

materialdif.com