High-viscosity resin offers superior structural strength and is ideal for applications requiring robust, durable finishes, while low-viscosity resin excels in intricate molds and detailed casting due to its easy flow and quick curing properties. Selecting between the two depends on project demands, as high-viscosity resins provide enhanced mechanical performance, whereas low-viscosity variants allow for precision and fine detail work. Both resins offer unique advantages that cater to specific industrial and artistic needs, optimizing results based on viscosity-driven characteristics.

Table of Comparison

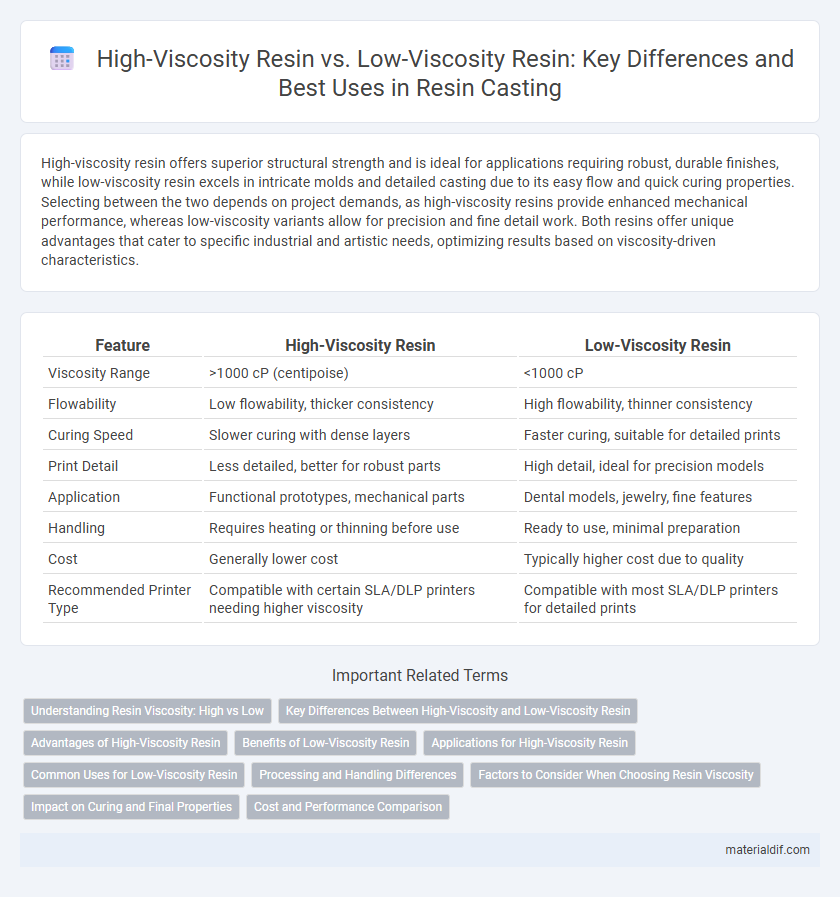

| Feature | High-Viscosity Resin | Low-Viscosity Resin |

|---|---|---|

| Viscosity Range | >1000 cP (centipoise) | <1000 cP |

| Flowability | Low flowability, thicker consistency | High flowability, thinner consistency |

| Curing Speed | Slower curing with dense layers | Faster curing, suitable for detailed prints |

| Print Detail | Less detailed, better for robust parts | High detail, ideal for precision models |

| Application | Functional prototypes, mechanical parts | Dental models, jewelry, fine features |

| Handling | Requires heating or thinning before use | Ready to use, minimal preparation |

| Cost | Generally lower cost | Typically higher cost due to quality |

| Recommended Printer Type | Compatible with certain SLA/DLP printers needing higher viscosity | Compatible with most SLA/DLP printers for detailed prints |

Understanding Resin Viscosity: High vs Low

High-viscosity resin offers greater thickness and slower flow, making it ideal for detailed sculpting and ensuring minimal sagging in vertical applications. Low-viscosity resin flows more easily, providing better penetration into intricate molds and faster curing times for efficient production. Selecting the appropriate resin viscosity depends on the specific requirements of the project, such as precision, curing speed, and mold complexity.

Key Differences Between High-Viscosity and Low-Viscosity Resin

High-viscosity resin exhibits a thicker consistency, resulting in slower flow rates and longer curing times, which provide enhanced structural strength and reduced shrinkage in applications such as 3D printing and casting. Low-viscosity resin, in contrast, flows more easily, allowing for finer detail capture, faster curing, and better penetration into molds or substrates, ideal for intricate designs and thin layers. The choice between high-viscosity and low-viscosity resin depends on the specific application requirements, including desired surface finish, mechanical properties, and processing speed.

Advantages of High-Viscosity Resin

High-viscosity resin offers superior mechanical strength and enhanced dimensional stability, making it ideal for applications requiring robust and durable materials. Its thicker consistency improves adhesion and reduces the risk of sagging or dripping during curing, leading to better surface finish and precision. This type of resin also provides greater resistance to deformation under stress, enhancing the longevity of the final product.

Benefits of Low-Viscosity Resin

Low-viscosity resin offers superior flowability, ensuring more precise and detailed filling of molds, which enhances the quality of intricate castings. This resin type reduces air bubble entrapment, resulting in smoother, defect-free surfaces ideal for high-precision applications. Its efficient wetting properties also improve adhesion to various substrates, making it a preferred choice for coatings, adhesives, and composite manufacturing.

Applications for High-Viscosity Resin

High-viscosity resin offers superior strength and durability, making it ideal for applications in structural adhesives, heavy-duty coatings, and composite materials used in automotive and aerospace industries. Its thicker consistency allows for better gap filling and enhanced bonding on rough or porous surfaces compared to low-viscosity resin. These properties ensure long-lasting performance in demanding environments, such as marine repairs and industrial equipment manufacturing.

Common Uses for Low-Viscosity Resin

Low-viscosity resin is ideal for applications requiring superior flow and deep penetration, such as in composite manufacturing, laminating, and coating processes. Its thin consistency allows for better wetting of fibers, making it popular in fiberglass and carbon fiber production for aerospace and automotive industries. This type of resin also excels in casting and molding projects where detail reproduction and minimal air entrapment are critical.

Processing and Handling Differences

High-viscosity resin demands higher temperatures and extended mixing times for proper flow, often requiring specialized equipment for efficient processing. Low-viscosity resin offers easier handling with faster curing times and better penetration into molds or substrates, reducing processing complexity. Differences in viscosity directly impact the choice of dispensing methods, mold release times, and final surface finish quality.

Factors to Consider When Choosing Resin Viscosity

Choosing between high-viscosity resin and low-viscosity resin depends on factors such as application type, curing time, and surface finish requirements. High-viscosity resin offers better gap-filling capabilities and is ideal for projects requiring thicker layers, whereas low-viscosity resin ensures easier flow and faster curing, suitable for detailed work and thin coatings. Consideration of working temperature, mixing ratios, and equipment compatibility also plays a critical role in selecting the appropriate resin viscosity.

Impact on Curing and Final Properties

High-viscosity resin exhibits slower curing times due to reduced molecular mobility, resulting in denser cross-linking and enhanced mechanical strength in the final product. Low-viscosity resin promotes faster curing through improved flow and better filler dispersion, yielding smoother surface finish and increased dimensional accuracy. The choice between high and low viscosity directly influences thermal stability, hardness, and overall durability of the cured resin composite.

Cost and Performance Comparison

High-viscosity resin generally incurs higher costs due to its formulation requiring more complex additives and processing methods, impacting overall production expenses. Performance-wise, high-viscosity resins offer superior mechanical strength and durability, making them ideal for applications demanding robust structural integrity. Low-viscosity resins are more cost-effective and facilitate easier molding and faster curing times, but they may compromise on mechanical performance and long-term stability.

High-Viscosity Resin vs Low-Viscosity Resin Infographic

materialdif.com

materialdif.com