Heat-cure resin offers superior strength and durability due to its polymerization process at elevated temperatures, making it ideal for long-lasting dental restorations and prosthetics. Room temperature-cure resin provides convenience and faster application without the need for specialized equipment, but it typically has lower mechanical properties and longer setting times compared to heat-cure alternatives. Choosing between these resins depends on the specific clinical requirements, balancing factors like strength, cure time, and equipment availability.

Table of Comparison

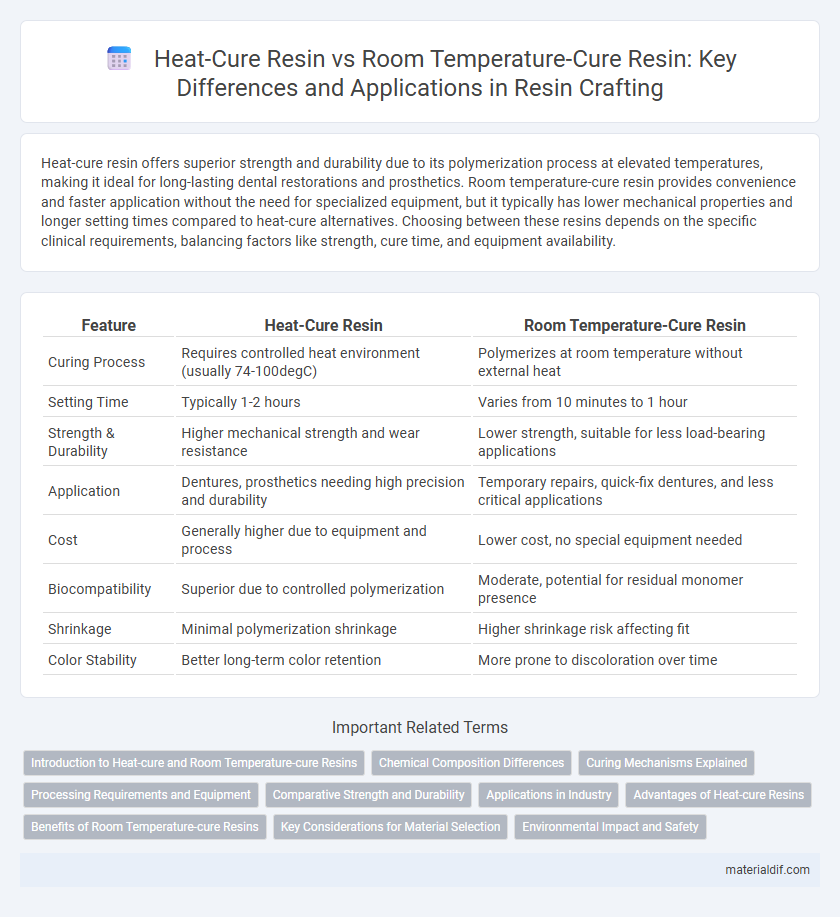

| Feature | Heat-Cure Resin | Room Temperature-Cure Resin |

|---|---|---|

| Curing Process | Requires controlled heat environment (usually 74-100degC) | Polymerizes at room temperature without external heat |

| Setting Time | Typically 1-2 hours | Varies from 10 minutes to 1 hour |

| Strength & Durability | Higher mechanical strength and wear resistance | Lower strength, suitable for less load-bearing applications |

| Application | Dentures, prosthetics needing high precision and durability | Temporary repairs, quick-fix dentures, and less critical applications |

| Cost | Generally higher due to equipment and process | Lower cost, no special equipment needed |

| Biocompatibility | Superior due to controlled polymerization | Moderate, potential for residual monomer presence |

| Shrinkage | Minimal polymerization shrinkage | Higher shrinkage risk affecting fit |

| Color Stability | Better long-term color retention | More prone to discoloration over time |

Introduction to Heat-cure and Room Temperature-cure Resins

Heat-cure resin polymerizes through the application of controlled high temperatures, resulting in enhanced mechanical strength and reduced porosity compared to other curing methods. Room temperature-cure resin solidifies at ambient conditions using chemical catalysts, offering convenience and ease of use but generally lower dimensional stability and durability. Both types of resins have specific applications in dentistry and industrial processes, depending on the balance required between processing time and material properties.

Chemical Composition Differences

Heat-cure resin typically contains initiators such as benzoyl peroxide that require elevated temperatures to activate polymerization, resulting in a densely cross-linked polymer network. Room temperature-cure resin often uses tertiary amines as activators combined with benzoyl peroxide, allowing polymerization at ambient temperatures but producing a polymer with lower cross-link density. These chemical composition differences directly influence mechanical properties, curing time, and biocompatibility of the resin materials.

Curing Mechanisms Explained

Heat-cure resin relies on elevated temperatures to initiate polymerization through free radical mechanisms, resulting in a more complete and controlled curing process that enhances mechanical properties. Room temperature-cure resin undergoes polymerization via chemical activators or catalysts that trigger curing at ambient conditions, often involving a redox reaction for efficient hardening without heat. Understanding these distinct curing mechanisms helps optimize resin selection based on application requirements, balancing cure time, strength, and processing conditions.

Processing Requirements and Equipment

Heat-cure resin demands specialized ovens or curing units capable of maintaining elevated temperatures typically between 120degC and 160degC, ensuring precise thermal control for optimal polymerization. In contrast, room temperature-cure resin requires only ambient environmental conditions, eliminating the need for costly heating equipment and reducing energy consumption. While heat-curing accelerates strength development and chemical resistance through controlled thermal activation, room temperature curing relies on chemical initiators or catalysts to initiate polymerization, allowing simpler processing setups but longer curing times.

Comparative Strength and Durability

Heat-cure resin exhibits superior strength and enhanced durability compared to room temperature-cure resin, making it the preferred choice for applications demanding long-lasting performance. The elevated curing temperature promotes a more complete polymerization process, resulting in a denser and more resilient material structure. Room temperature-cure resin, although convenient, typically offers lower mechanical strength and is more susceptible to wear and degradation over time.

Applications in Industry

Heat-cure resin is widely used in dental prosthetics and aerospace industries due to its superior mechanical strength and thermal stability. Room temperature-cure resin finds applications in automotive repairs and small-scale manufacturing where quick setting without specialized equipment is required. Both types offer unique benefits based on curing methods, influencing their selection in industrial applications.

Advantages of Heat-cure Resins

Heat-cure resins offer superior mechanical strength and enhanced durability compared to room temperature-cure resins, making them ideal for long-lasting dental prosthetics and industrial applications. The polymerization process under elevated temperatures results in improved cross-linking, which reduces residual monomer content and increases resistance to wear and chemical degradation. These properties ensure heat-cure resins provide better biocompatibility and dimensional stability in high-stress environments.

Benefits of Room Temperature-cure Resins

Room temperature-cure resins offer significant advantages including ease of use without the need for specialized heating equipment, reducing energy consumption and operational costs. These resins provide faster curing times in ambient conditions, enabling quicker production cycles and enhanced workflow efficiency. Their low thermal stress during curing minimizes the risk of deformation or damage to delicate substrates, making them ideal for applications in electronics and fine art restoration.

Key Considerations for Material Selection

Heat-cure resin offers superior mechanical strength and wear resistance compared to room temperature-cure resin, making it ideal for long-term and high-stress dental or prototyping applications. Room temperature-cure resin provides convenience and faster processing times without requiring specialized equipment, suitable for quick repairs and low-load components. Material selection should prioritize the balance between required durability, curing time, and equipment availability to optimize performance and cost-effectiveness.

Environmental Impact and Safety

Heat-cure resin typically requires higher energy consumption during polymerization, increasing its environmental footprint compared to room temperature-cure resin, which cures without external heating and thus conserves energy. Room temperature-cure resins often release fewer volatile organic compounds (VOCs), reducing airborne toxic exposure and enhancing user safety. However, heat-cure resins generally offer improved physical properties and lower residual monomer content, potentially minimizing prolonged chemical exposure risks.

Heat-cure Resin vs Room Temperature-cure Resin Infographic

materialdif.com

materialdif.com