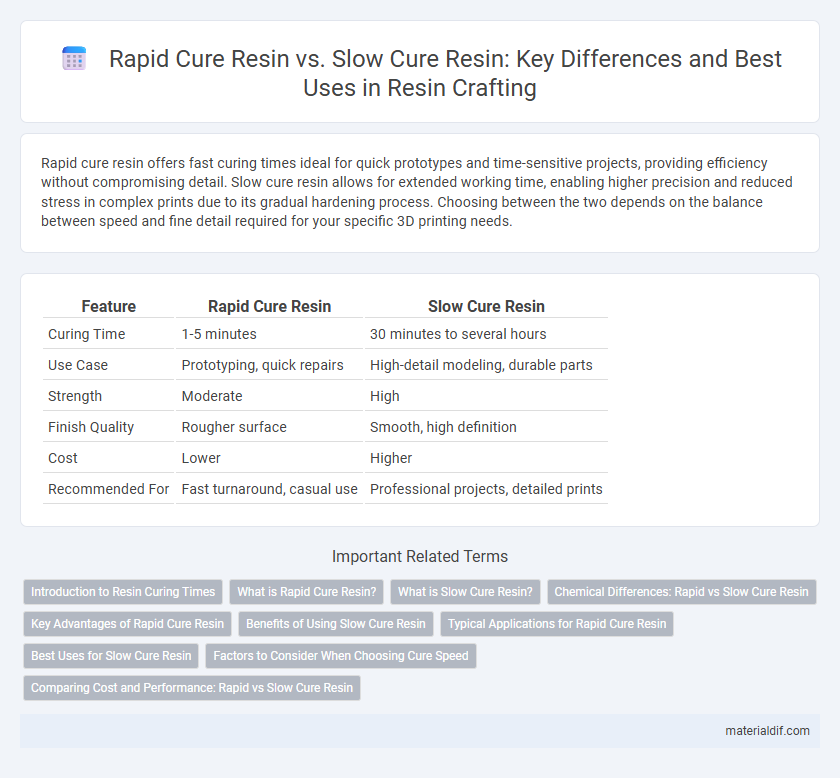

Rapid cure resin offers fast curing times ideal for quick prototypes and time-sensitive projects, providing efficiency without compromising detail. Slow cure resin allows for extended working time, enabling higher precision and reduced stress in complex prints due to its gradual hardening process. Choosing between the two depends on the balance between speed and fine detail required for your specific 3D printing needs.

Table of Comparison

| Feature | Rapid Cure Resin | Slow Cure Resin |

|---|---|---|

| Curing Time | 1-5 minutes | 30 minutes to several hours |

| Use Case | Prototyping, quick repairs | High-detail modeling, durable parts |

| Strength | Moderate | High |

| Finish Quality | Rougher surface | Smooth, high definition |

| Cost | Lower | Higher |

| Recommended For | Fast turnaround, casual use | Professional projects, detailed prints |

Introduction to Resin Curing Times

Rapid cure resin solidifies within minutes, making it ideal for projects requiring quick turnaround and minimal wait time. Slow cure resin, on the other hand, can take several hours to fully harden, allowing for better bubble release and enhanced clarity. Understanding the differences in curing times helps optimize resin application for specific crafting or industrial needs.

What is Rapid Cure Resin?

Rapid Cure Resin is a type of photo-reactive material designed to harden quickly when exposed to UV or visible light sources, making it ideal for fast prototyping and rapid manufacturing. This resin typically has a lower viscosity and optimized photoinitiators that accelerate polymerization, reducing curing time from hours to minutes. Its applications span from dental restorations to detailed 3D printing, where speed and precision are critical.

What is Slow Cure Resin?

Slow cure resin is a type of epoxy resin known for its extended curing time, allowing more working time before hardening. This resin is ideal for complex projects that require precise application and adjustment, as it reduces the risk of bubbles and imperfections. Its longer curing process enhances durability and strength, making it suitable for casting, embedding, and detailed art creations.

Chemical Differences: Rapid vs Slow Cure Resin

Rapid cure resin undergoes a faster polymerization process due to higher concentrations of initiators and accelerators, resulting in a shorter pot life but quicker solidification. Slow cure resin contains lower levels of these reactive components, allowing extended working time and gradual cross-linking that enhances mechanical properties and reduces internal stresses. The chemical formulation differences between rapid and slow cure resins directly influence their viscosity, heat generation, and final material strength.

Key Advantages of Rapid Cure Resin

Rapid cure resin offers significant advantages including faster production times, enabling manufacturers to reduce overall project turnaround and increase efficiency. Its quick hardening process allows for rapid prototyping and accelerated repair workflows, minimizing downtime in critical applications. Moreover, rapid cure resins often result in improved energy savings due to shorter curing cycles, supporting more sustainable manufacturing practices.

Benefits of Using Slow Cure Resin

Slow cure resin offers enhanced control over curing time, allowing for precise adjustments to achieve optimal hardness and finish. This resin type reduces the risk of cracks and stress during the curing process, improving the durability and longevity of the final product. Its extended working time benefits complex casting projects, ensuring detailed and high-quality results with minimal defects.

Typical Applications for Rapid Cure Resin

Rapid cure resin is primarily used in applications demanding quick turnaround times such as prototyping, emergency repairs, and fast-paced manufacturing processes. It is ideal for producing small batches of parts, dental molds, and jewelry casting where reducing wait time enhances productivity. Typical industries leveraging rapid cure resin include automotive, aerospace, and consumer electronics for rapid functional testing and product development.

Best Uses for Slow Cure Resin

Slow cure resin is ideal for applications requiring extended working time and precise detail, such as intricate jewelry making and complex mold casting. Its longer curing period allows for better handling and bubble release, ensuring a smoother finish and fewer defects. Slow cure resin is preferred in projects where durability and clarity are critical, making it suitable for high-quality art pieces and prototyping.

Factors to Consider When Choosing Cure Speed

When selecting between rapid cure resin and slow cure resin, consider factors such as application complexity, required mechanical properties, and working time availability. Rapid cure resin offers faster hardening, ideal for quick turnarounds but may sacrifice some strength or finish quality compared to slow cure resin. Slow cure resin provides extended working time for detailed, high-precision projects and typically results in superior durability and surface smoothness.

Comparing Cost and Performance: Rapid vs Slow Cure Resin

Rapid cure resin typically costs more due to its advanced chemical formulation that enables faster hardening times, reducing production cycles and labor expenses. Slow cure resin, though less expensive upfront, often provides superior mechanical properties and durability, making it ideal for applications requiring enhanced strength and heat resistance. Evaluating cost against performance depends on the specific project's priorities, where rapid cure benefits high throughput and slow cure ensures long-term reliability.

Rapid Cure Resin vs Slow Cure Resin Infographic

materialdif.com

materialdif.com