Laminating resin is designed for impregnating fibers and creating composite materials with high strength and durability, making it ideal for structural applications. Coating resin, on the other hand, is formulated to provide a smooth, protective surface finish that enhances gloss and resistance to environmental damage. Choosing between laminating and coating resin depends on whether the priority is structural reinforcement or surface protection.

Table of Comparison

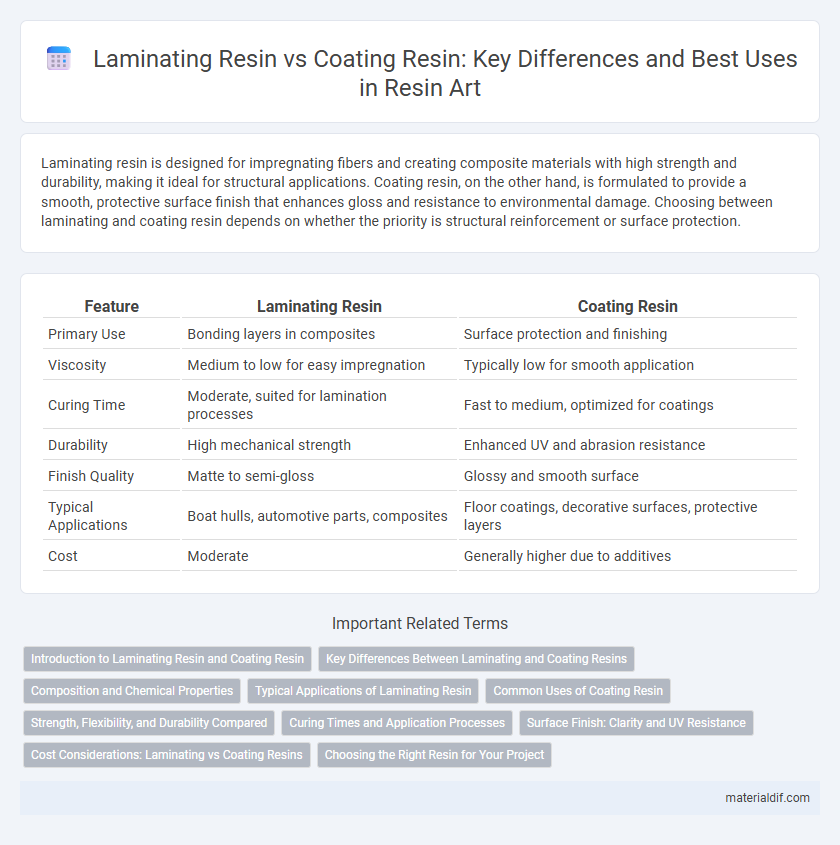

| Feature | Laminating Resin | Coating Resin |

|---|---|---|

| Primary Use | Bonding layers in composites | Surface protection and finishing |

| Viscosity | Medium to low for easy impregnation | Typically low for smooth application |

| Curing Time | Moderate, suited for lamination processes | Fast to medium, optimized for coatings |

| Durability | High mechanical strength | Enhanced UV and abrasion resistance |

| Finish Quality | Matte to semi-gloss | Glossy and smooth surface |

| Typical Applications | Boat hulls, automotive parts, composites | Floor coatings, decorative surfaces, protective layers |

| Cost | Moderate | Generally higher due to additives |

Introduction to Laminating Resin and Coating Resin

Laminating resin, primarily composed of polyester or epoxy, is designed to bond layers of fiberglass, wood, or fabric in composite materials, providing structural strength and durability. Coating resin, often polyurethane or epoxy-based, serves as a protective surface layer, offering resistance to moisture, UV rays, and abrasion while enhancing gloss and smoothness. Both resin types differ in viscosity, curing time, and mechanical properties tailored to specific applications in manufacturing and repair processes.

Key Differences Between Laminating and Coating Resins

Laminating resin is designed for bonding and sealing layers of composite materials, offering high mechanical strength and excellent adhesion to fabrics such as fiberglass or carbon fiber. Coating resin primarily serves as a protective layer, providing chemical resistance, UV stability, and a smooth finish on surfaces without the need for structural strength. The key differences lie in laminating resins' focus on structural integrity and load-bearing capacity, while coating resins emphasize surface protection and aesthetic enhancement.

Composition and Chemical Properties

Laminating resin typically consists of polyester or epoxy bases designed for high strength, offering excellent adhesion and chemical resistance ideal for structural applications. Coating resin, often made from polyurethane or acrylic compounds, emphasizes flexibility and UV resistance to provide durable surface protection. The chemical properties of laminating resins favor rigidity and toughness, whereas coating resins prioritize elasticity and environmental durability.

Typical Applications of Laminating Resin

Laminating resin is typically used in the production of composite materials, including fiberglass-reinforced plastics for automotive, marine, and construction industries. It provides excellent adhesion and mechanical strength, making it ideal for creating structural components and layers in boat hulls, wind turbine blades, and sports equipment. This type of resin offers enhanced durability and resistance to environmental factors, ensuring long-lasting performance in demanding applications.

Common Uses of Coating Resin

Coating resin is primarily used to create protective and decorative surfaces on wood, metal, and concrete, enhancing resistance to moisture, abrasion, and UV damage. It is common in flooring, boat decks, automotive finishes, and artwork to provide a clear, glossy, and durable finish. Unlike laminating resin, which is designed for structural composites, coating resin excels as a surface layer for sealing and aesthetic enhancement.

Strength, Flexibility, and Durability Compared

Laminating resin offers superior strength and toughness, making it ideal for structural applications requiring high load-bearing capacity, while coating resin provides enhanced flexibility and abrasion resistance suitable for protective surface finishes. Durability in laminating resin is generally higher due to its thicker, reinforced layers that withstand mechanical stresses, whereas coating resin excels in weather resistance and chemical protection. Choosing between the two depends on specific project requirements for mechanical performance versus surface protection.

Curing Times and Application Processes

Laminating resin typically features longer curing times, ranging from several hours to overnight, which allows for better adhesion and layering in composite materials like fiberglass or carbon fiber. Coating resin cures more rapidly, often within 30 minutes to a few hours, making it ideal for surface finishing and protective coatings on wood, metal, or concrete. Application processes differ as laminating resin is applied in multiple layers with fabric reinforcement, while coating resin is spread thinly to create a smooth, durable surface.

Surface Finish: Clarity and UV Resistance

Laminating resin offers superior clarity with a smooth, high-gloss surface ideal for embedding and preserving objects, maintaining its transparency over time. Coating resin, formulated for enhanced UV resistance, protects surfaces from yellowing and degradation under prolonged sun exposure. Both resins provide durable finishes, but coating resin excels in outdoor applications requiring sustained aesthetic integrity.

Cost Considerations: Laminating vs Coating Resins

Laminating resin generally incurs higher costs due to its thicker application and superior mechanical properties required for structural integrity. Coating resin tends to be more affordable as it is applied in thinner layers primarily for surface protection and aesthetic enhancement. Budget planning should account for the intended use, volume needed, and performance expectations when choosing between laminating and coating resins.

Choosing the Right Resin for Your Project

Laminating resin offers superior strength and flexibility, making it ideal for composite structures requiring durability and impact resistance. Coating resin provides a smooth, glossy finish with excellent UV protection, perfect for surface sealing and aesthetic enhancement. Selecting the right resin depends on whether structural integrity or surface appearance is the priority in your project.

Laminating Resin vs Coating Resin Infographic

materialdif.com

materialdif.com