UV resin cures quickly under ultraviolet light, offering faster project completion and a smoother finish compared to standard epoxy. Standard epoxy requires longer curing times and often provides greater durability and chemical resistance for heavy-duty applications. Choosing between UV resin and epoxy depends on the desired curing speed, surface finish, and application strength needed for the project.

Table of Comparison

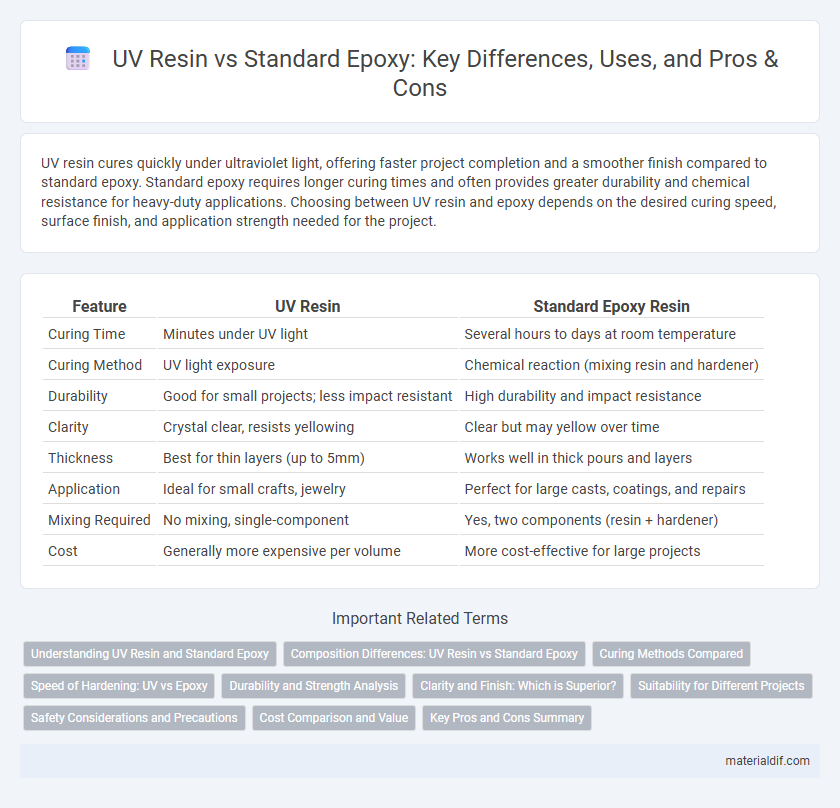

| Feature | UV Resin | Standard Epoxy Resin |

|---|---|---|

| Curing Time | Minutes under UV light | Several hours to days at room temperature |

| Curing Method | UV light exposure | Chemical reaction (mixing resin and hardener) |

| Durability | Good for small projects; less impact resistant | High durability and impact resistance |

| Clarity | Crystal clear, resists yellowing | Clear but may yellow over time |

| Thickness | Best for thin layers (up to 5mm) | Works well in thick pours and layers |

| Application | Ideal for small crafts, jewelry | Perfect for large casts, coatings, and repairs |

| Mixing Required | No mixing, single-component | Yes, two components (resin + hardener) |

| Cost | Generally more expensive per volume | More cost-effective for large projects |

Understanding UV Resin and Standard Epoxy

UV resin cures quickly under ultraviolet light, offering a fast, clear finish ideal for small crafts and jewelry. Standard epoxy resin requires mixing resin and hardener, curing over several hours, and provides a strong, durable surface suited for coatings and large projects. Understanding the differences in curing time, application, and durability helps select the right resin for specific crafting needs.

Composition Differences: UV Resin vs Standard Epoxy

UV resin contains photoinitiators that enable rapid curing when exposed to ultraviolet light, whereas standard epoxy resin relies on a chemical catalyst and hardener mixture to initiate a slower curing process. The formula of UV resin typically includes acrylates or methacrylates, providing flexibility and quick hardening, while epoxy resins are composed of epoxy oligomers and polyamine hardeners that yield a stronger, more durable finish. These compositional differences influence their application suitability, with UV resin favored for fast, detailed crafts and standard epoxy preferred for structural or heavy-duty coatings.

Curing Methods Compared

UV resin cures rapidly when exposed to ultraviolet light, typically hardening within minutes, making it ideal for quick projects and detailed work. Standard epoxy resin cures through a chemical reaction between resin and hardener, requiring several hours to days to fully set, offering greater depth and strength for larger applications. UV resin's curing process can be precisely controlled with light exposure, while standard epoxy's curing time depends on temperature and mixing ratios.

Speed of Hardening: UV vs Epoxy

UV resin hardens significantly faster than standard epoxy resin, typically curing within minutes under a UV light source. Standard epoxy resin requires a longer curing time, often ranging from several hours to days depending on the formulation and environmental conditions. The rapid curing of UV resin makes it ideal for quick projects and detailed work, while epoxy's slower hardening allows for deeper pours and more working time.

Durability and Strength Analysis

UV resin cures rapidly under ultraviolet light, resulting in a hard, durable surface with excellent resistance to yellowing and cracking, making it ideal for small projects and detailed work. Standard epoxy resin offers superior strength and long-term durability, with higher impact resistance and better adhesion to various substrates, suitable for heavy-duty applications and structural uses. While UV resin provides convenience and quick curing, epoxy resin outperforms in strength and durability for demanding environments.

Clarity and Finish: Which is Superior?

UV resin offers superior clarity with its crystal-clear finish and minimal yellowing over time, making it ideal for detailed art and jewelry projects requiring a flawless, glass-like appearance. Standard epoxy can achieve a durable, glossy finish but often exhibits slight ambering as it ages, which may affect clarity in transparent applications. For projects prioritizing long-term brilliance and sharp detail, UV resin outperforms standard epoxy in maintaining pristine optical clarity and a smooth surface finish.

Suitability for Different Projects

UV resin cures rapidly under UV light, making it ideal for small-scale projects like jewelry, embellishments, and repairs requiring quick turnaround. Standard epoxy resin offers longer working time and superior strength, preferred for larger applications such as countertops, river tables, and deep molds. Selecting between UV resin and epoxy depends on project size, curing time needs, and desired durability.

Safety Considerations and Precautions

UV resin cures quickly under ultraviolet light, reducing the risk of prolonged exposure to uncured chemicals, but it may emit stronger fumes requiring proper ventilation and protective masks. Standard epoxy resin typically takes hours to cure and often contains bisphenol A (BPA) and volatile organic compounds (VOCs), necessitating gloves and respirators due to potential skin irritation and inhalation hazards. Both types require working in well-ventilated spaces, using nitrile gloves, and avoiding direct skin contact to minimize allergic reactions and long-term health effects.

Cost Comparison and Value

UV resin typically costs more per ounce than standard epoxy but cures significantly faster, offering greater efficiency for small projects and rapid prototyping. Standard epoxy resins provide a lower price point with longer curing times, better suited for larger applications where time is less critical. Evaluating value involves balancing upfront material costs against labor time savings and desired project turnaround.

Key Pros and Cons Summary

UV resin cures rapidly under ultraviolet light, enabling quick project completion with minimal waiting time and excellent detail preservation; however, it often has limited depth per layer and can yellow over time. Standard epoxy resin offers superior durability, chemical resistance, and a longer working time for large pours, but requires hours to days to fully cure and may involve mixing inaccuracies. Choosing between UV resin and standard epoxy depends on project size, curing speed requirements, and long-term finish quality.

UV Resin vs Standard Epoxy Infographic

materialdif.com

materialdif.com