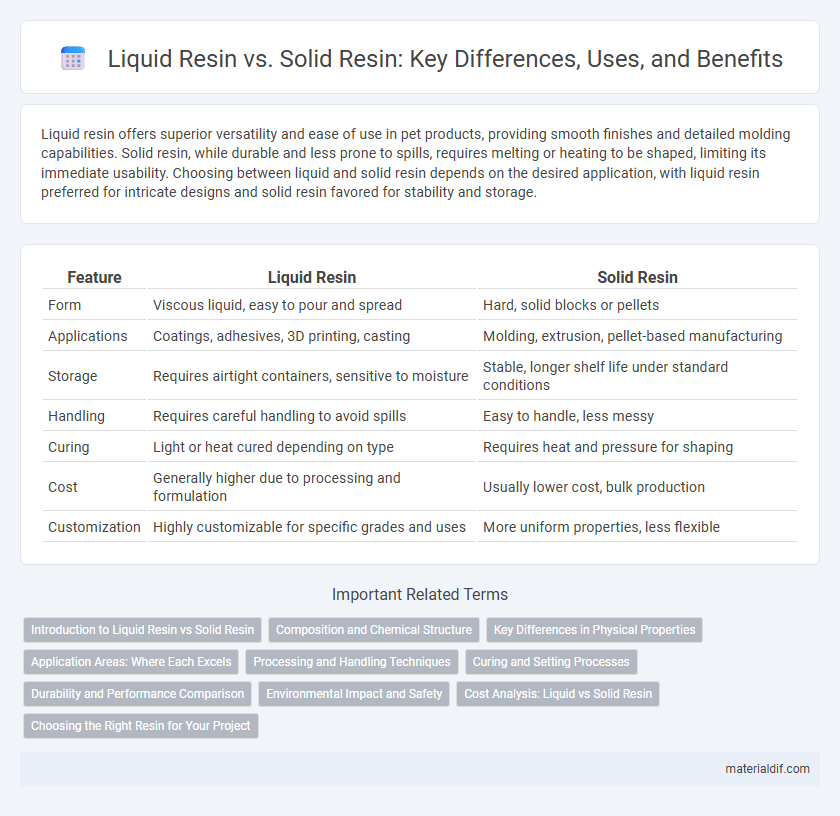

Liquid resin offers superior versatility and ease of use in pet products, providing smooth finishes and detailed molding capabilities. Solid resin, while durable and less prone to spills, requires melting or heating to be shaped, limiting its immediate usability. Choosing between liquid and solid resin depends on the desired application, with liquid resin preferred for intricate designs and solid resin favored for stability and storage.

Table of Comparison

| Feature | Liquid Resin | Solid Resin |

|---|---|---|

| Form | Viscous liquid, easy to pour and spread | Hard, solid blocks or pellets |

| Applications | Coatings, adhesives, 3D printing, casting | Molding, extrusion, pellet-based manufacturing |

| Storage | Requires airtight containers, sensitive to moisture | Stable, longer shelf life under standard conditions |

| Handling | Requires careful handling to avoid spills | Easy to handle, less messy |

| Curing | Light or heat cured depending on type | Requires heat and pressure for shaping |

| Cost | Generally higher due to processing and formulation | Usually lower cost, bulk production |

| Customization | Highly customizable for specific grades and uses | More uniform properties, less flexible |

Introduction to Liquid Resin vs Solid Resin

Liquid resin offers enhanced versatility and ease of application compared to solid resin, making it ideal for various casting and coating processes. Solid resin, typically supplied in pellets or blocks, requires melting before use and provides greater stability during storage and transport. Selecting between liquid and solid resin depends on the specific manufacturing requirements, curing methods, and desired end-product properties.

Composition and Chemical Structure

Liquid resin consists primarily of low-viscosity monomers and oligomers that polymerize upon curing, allowing for easy flow and precise molding. Solid resin, often in pellet or powder form, contains pre-polymerized or partially polymerized compounds with a more stable chemical structure, resulting in higher melting points and different processing requirements. The difference in composition and chemical structure between liquid and solid resins directly affects their application methods, curing behavior, and final material properties.

Key Differences in Physical Properties

Liquid resin exhibits low viscosity and fluidity, allowing easy molding and penetration into intricate molds, while solid resin maintains a rigid, stable form with high density and hardness. Liquid resin typically cures through polymerization triggered by heat or UV light, transitioning from a liquid to a solid state, whereas solid resin is pre-hardened and requires melting or reshaping under specific conditions. These physical property differences determine their applications in industries such as coatings, adhesives, and 3D printing, where flowability and hardness are critical factors.

Application Areas: Where Each Excels

Liquid resin excels in applications requiring intricate detailing and smooth finishes, such as jewelry making, dental molds, and custom prototypes due to its low viscosity and ability to capture fine features. Solid resin is preferred in structural uses like furniture, flooring, and industrial composites where durability, rigidity, and ease of handling are critical. Both types serve distinct roles across industries, with liquid resin favored for precision and aesthetics, and solid resin for strength and longevity.

Processing and Handling Techniques

Liquid resin offers ease of application through pouring or brushing, enabling seamless filling of molds and detailed surface finishes, while requiring controlled curing conditions such as temperature and humidity to avoid defects. Solid resin, often supplied as pellets or sheets, necessitates melting or dissolving before use, demanding precise temperature control in processing equipment like extruders or presses to achieve uniform flow and prevent degradation. Handling liquid resin requires careful management of viscosity and pot life, whereas solid resin handling focuses on storage stability and accurate dosing for consistent processing outcomes.

Curing and Setting Processes

Liquid resin cures through a chemical reaction initiated by heat, UV light, or catalysts, allowing for precise control over setting times and resulting in a smooth, durable finish. Solid resin typically requires melting and subsequent cooling to harden, which can lead to longer setting times and possible inconsistencies in texture. Understanding the distinct curing and setting processes of liquid versus solid resin is essential for selecting the right material for applications such as coatings, adhesives, or 3D printing.

Durability and Performance Comparison

Liquid resin exhibits superior durability in applications requiring flexibility and impact resistance, making it ideal for coatings and adhesives. Solid resin offers enhanced structural performance with higher strength and rigidity, suitable for molded parts and high-load components. Performance varies with application type, where liquid resin ensures better shock absorption, while solid resin withstands greater mechanical stress.

Environmental Impact and Safety

Liquid resin typically poses higher environmental risks due to volatile organic compounds (VOCs) emissions and potential skin and respiratory irritation during handling. Solid resin, being more stable and less prone to off-gassing, offers improved safety and reduced ecological footprint by minimizing hazardous chemical exposure. Proper disposal methods for both forms are essential to prevent soil and water contamination, with solid resin generally easier to manage safely.

Cost Analysis: Liquid vs Solid Resin

Liquid resin typically offers a lower upfront cost compared to solid resin, making it a more budget-friendly option for large-scale or continuous applications. Solid resin often incurs higher initial expenses due to processing and packaging, but it can reduce waste and storage costs, resulting in long-term savings. Analyzing factors such as application volume, storage requirements, and material efficiency is critical for an accurate cost comparison between liquid and solid resin formats.

Choosing the Right Resin for Your Project

Liquid resin offers superior detail and smooth finishes, making it ideal for intricate molds and delicate art projects, while solid resin provides greater durability and ease of handling for larger or structural applications. Consider factors such as curing time, application method, and desired end-use when choosing between liquid and solid resin to ensure optimal performance. Selecting the appropriate resin type enhances the longevity, appearance, and functionality of your project.

Liquid Resin vs Solid Resin Infographic

materialdif.com

materialdif.com