Bisphenol A resin offers excellent mechanical strength and chemical resistance, making it ideal for applications requiring durability and toughness. Novolac resin, characterized by its superior heat resistance and thermal stability, is commonly used in electrical insulation and high-temperature settings. Choosing between Bisphenol A and Novolac resins depends on the specific performance requirements, such as temperature tolerance versus mechanical robustness.

Table of Comparison

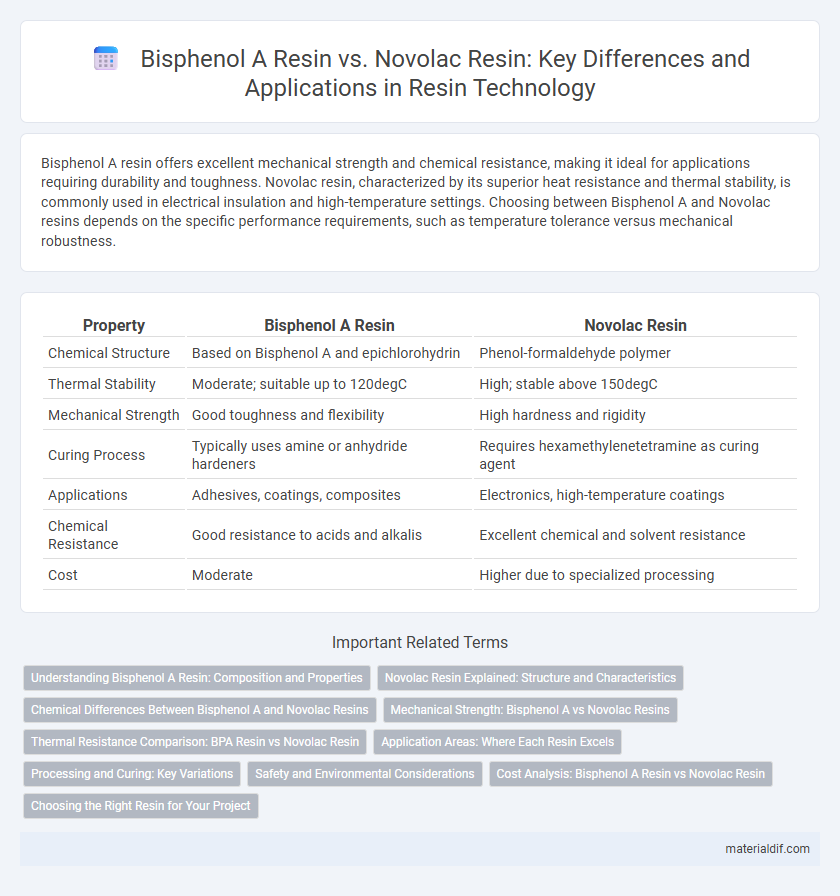

| Property | Bisphenol A Resin | Novolac Resin |

|---|---|---|

| Chemical Structure | Based on Bisphenol A and epichlorohydrin | Phenol-formaldehyde polymer |

| Thermal Stability | Moderate; suitable up to 120degC | High; stable above 150degC |

| Mechanical Strength | Good toughness and flexibility | High hardness and rigidity |

| Curing Process | Typically uses amine or anhydride hardeners | Requires hexamethylenetetramine as curing agent |

| Applications | Adhesives, coatings, composites | Electronics, high-temperature coatings |

| Chemical Resistance | Good resistance to acids and alkalis | Excellent chemical and solvent resistance |

| Cost | Moderate | Higher due to specialized processing |

Understanding Bisphenol A Resin: Composition and Properties

Bisphenol A resin, a thermoplastic polymer formed from the condensation of bisphenol A and epichlorohydrin, exhibits high mechanical strength and excellent chemical resistance. This resin features a rigid aromatic backbone that contributes to its thermal stability and durability, making it suitable for coatings, adhesives, and electronic components. Compared to novolac resin, which is a phenol-formaldehyde-based thermoset with superior heat resistance, bisphenol A resin offers enhanced flexibility and clarity but generally lower thermal resistance.

Novolac Resin Explained: Structure and Characteristics

Novolac resin is a thermosetting phenolic resin formed by the acid-catalyzed reaction of phenol with formaldehyde, resulting in a linear polymer with methylol groups that require curing agents such as hexamethylenetetramine for cross-linking. Its structure grants high thermal stability, chemical resistance, and mechanical strength, making it ideal for applications like coatings, adhesives, and composites. Unlike Bisphenol A resin, which is a thermoplastic epoxy resin with flexible ether linkages, Novolac resin offers superior heat resistance and dimensional stability in demanding industrial environments.

Chemical Differences Between Bisphenol A and Novolac Resins

Bisphenol A resin is a thermoplastic polymer formed by the condensation of bisphenol A with epichlorohydrin, characterized by its rigid aromatic backbone and hydroxyl groups that provide chemical resistance and mechanical strength. Novolac resin, created through the acid-catalyzed polymerization of phenol with formaldehyde, is a thermosetting phenolic resin with a high cross-link density, offering superior thermal stability and chemical resistance compared to Bisphenol A resin. The key chemical difference lies in Bisphenol A resin's epoxy functionality allowing for curing with amines or anhydrides, whereas Novolac resin requires curing agents like hexamethylenetetramine to form a three-dimensional network.

Mechanical Strength: Bisphenol A vs Novolac Resins

Bisphenol A resin exhibits high mechanical strength due to its rigid aromatic backbone and strong intermolecular hydrogen bonding, making it resistant to deformation under stress. Novolac resin also offers excellent mechanical properties, with enhanced thermal stability and hardness derived from its phenolic structure and dense cross-linking network. Compared to Bisphenol A resin, Novolac resin typically provides superior resistance to mechanical wear and impact, making it ideal for heavy-duty applications.

Thermal Resistance Comparison: BPA Resin vs Novolac Resin

Bisphenol A (BPA) resin exhibits moderate thermal resistance, withstanding temperatures up to approximately 120-150degC before degradation, making it suitable for general-purpose applications. Novolac resin offers superior thermal resistance, maintaining stability at temperatures exceeding 200degC due to its highly cross-linked phenolic structure. This enhanced heat tolerance makes Novolac resin preferable in high-temperature environments such as industrial molding and electronics manufacturing.

Application Areas: Where Each Resin Excels

Bisphenol A resin is widely used in electronics, automotive components, and coatings due to its excellent mechanical strength, chemical resistance, and thermal stability. Novolac resin excels in high-temperature applications such as adhesives, molding compounds, and corrosion-resistant coatings, benefiting industries like aerospace, electrical insulation, and heavy machinery. The choice between Bisphenol A and Novolac resins depends on specific performance requirements, with Bisphenol A favored for structural durability and Novolac preferred for thermal resistance and chemical durability.

Processing and Curing: Key Variations

Bisphenol A resin cures through a condensation reaction with formaldehyde, requiring higher temperatures and longer times, making it suitable for molding and casting applications. Novolac resin, a phenol-formaldehyde resin, demands a curing agent like hexamethylenetetramine to initiate crosslinking, enabling precise control over curing conditions and resulting in superior thermal stability. Processing Bisphenol A resin often involves thermoplastic behavior, while Novolac resin behaves as a thermoset, impacting their respective processing methodologies and final product durability.

Safety and Environmental Considerations

Bisphenol A resin poses significant health risks due to its potential endocrine-disrupting effects, leading to strict regulatory restrictions in many countries, while Novolac resin is generally regarded as safer with lower toxicity. Novolac resins exhibit better chemical stability and resistance to environmental degradation, resulting in fewer harmful emissions during use and disposal compared to Bisphenol A-based resins. The production and disposal processes of Novolac resins also generate less hazardous waste, making them a more environmentally sustainable choice in industrial applications.

Cost Analysis: Bisphenol A Resin vs Novolac Resin

Bisphenol A resin generally offers lower production costs compared to novolac resin due to its simpler synthesis and higher availability of raw materials. Novolac resin, while more expensive, provides superior thermal stability and chemical resistance, often justifying its cost in high-performance applications. The overall cost analysis highlights bisphenol A resin as a cost-effective choice for large-scale manufacturing, whereas novolac resin is preferred when performance requirements outweigh budget constraints.

Choosing the Right Resin for Your Project

Bisphenol A resin offers excellent mechanical strength, chemical resistance, and durability, making it ideal for applications requiring high impact resistance and thermal stability. Novolac resin provides superior chemical resistance and heat stability, especially in harsh environments, making it suitable for coatings, adhesives, and electronic insulation. Selecting the right resin depends on project requirements such as temperature tolerance, chemical exposure, and mechanical demands, with Bisphenol A resin preferred for structural uses and Novolac resin favored for high-performance chemical resistance.

Bisphenol A resin vs Novolac resin Infographic

materialdif.com

materialdif.com