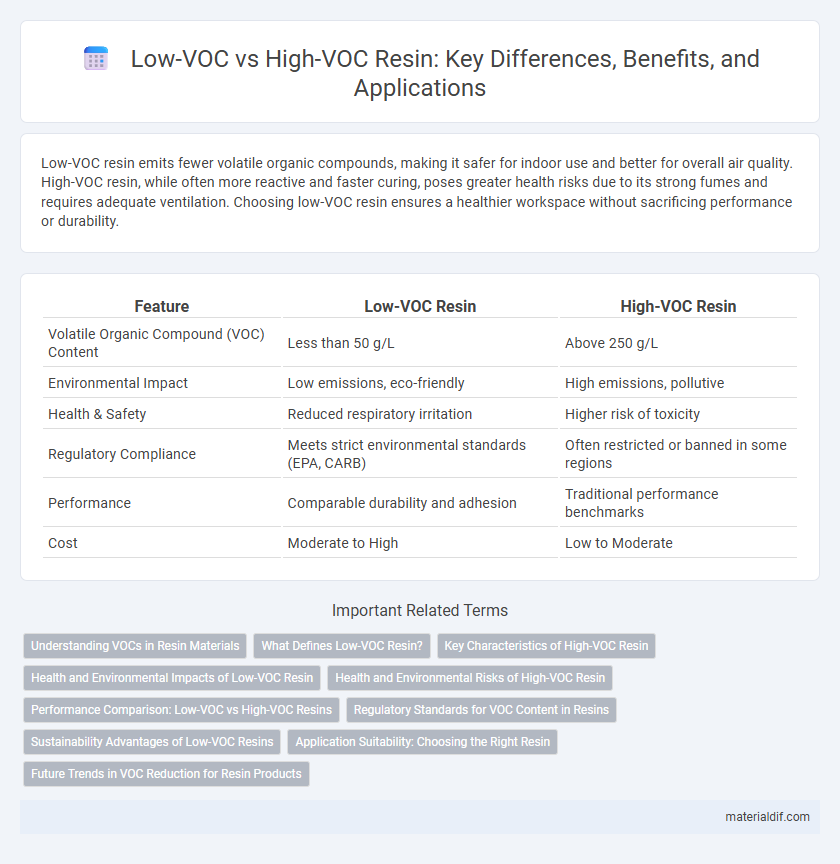

Low-VOC resin emits fewer volatile organic compounds, making it safer for indoor use and better for overall air quality. High-VOC resin, while often more reactive and faster curing, poses greater health risks due to its strong fumes and requires adequate ventilation. Choosing low-VOC resin ensures a healthier workspace without sacrificing performance or durability.

Table of Comparison

| Feature | Low-VOC Resin | High-VOC Resin |

|---|---|---|

| Volatile Organic Compound (VOC) Content | Less than 50 g/L | Above 250 g/L |

| Environmental Impact | Low emissions, eco-friendly | High emissions, pollutive |

| Health & Safety | Reduced respiratory irritation | Higher risk of toxicity |

| Regulatory Compliance | Meets strict environmental standards (EPA, CARB) | Often restricted or banned in some regions |

| Performance | Comparable durability and adhesion | Traditional performance benchmarks |

| Cost | Moderate to High | Low to Moderate |

Understanding VOCs in Resin Materials

Low-VOC resin contains significantly reduced levels of volatile organic compounds, which minimizes harmful emissions during curing and usage, promoting healthier indoor air quality and environmental safety. High-VOC resin releases a greater concentration of volatile organic compounds, contributing to stronger odors and increased health risks such as respiratory irritation and long-term exposure hazards. Understanding the chemical composition and emission profiles of VOCs in resin materials is essential for selecting products that meet regulatory standards and user safety preferences.

What Defines Low-VOC Resin?

Low-VOC resin is defined by its reduced emission of volatile organic compounds during curing and use, resulting in lower indoor air pollution and better environmental safety compared to high-VOC resin. It typically contains less than 0.5% VOC content by weight, meeting stringent regulatory standards such as those set by the EPA and California Air Resources Board (CARB). Low-VOC resins are favored in applications requiring enhanced air quality, including indoor coatings, adhesives, and composite materials.

Key Characteristics of High-VOC Resin

High-VOC resin contains volatile organic compounds exceeding 5% by weight, which contribute to stronger odors and increased emissions during curing. Its key characteristics include faster curing times and enhanced adhesive strength, making it suitable for industrial applications requiring quick set times. However, the higher VOC content poses environmental and health risks, necessitating proper ventilation and safety measures during use.

Health and Environmental Impacts of Low-VOC Resin

Low-VOC resin significantly reduces the emission of harmful volatile organic compounds, improving indoor air quality and minimizing respiratory health risks. This resin type contributes to lower environmental pollution by decreasing the release of toxic chemicals that can form ground-level ozone and smog. Choosing low-VOC resin supports sustainable manufacturing practices and aligns with strict regulatory standards aimed at protecting ecosystems and public health.

Health and Environmental Risks of High-VOC Resin

High-VOC resin emits significant levels of volatile organic compounds, which contribute to indoor air pollution and pose respiratory health risks such as asthma and lung irritation. Prolonged exposure to these toxic emissions can lead to chronic health issues and exacerbate cardiovascular problems. Environmentally, high-VOC resin accelerates smog formation and increases greenhouse gas contributions, intensifying air quality degradation and climate change effects.

Performance Comparison: Low-VOC vs High-VOC Resins

Low-VOC resins typically exhibit reduced emissions of volatile organic compounds, contributing to improved indoor air quality without significantly compromising curing time and mechanical strength compared to high-VOC resins. High-VOC resins often provide faster curing rates and higher adhesion properties, making them suitable for industrial applications where rapid processing is essential. However, low-VOC resins demonstrate enhanced environmental compliance and lower toxicity, aligning with stricter regulatory standards while maintaining competitive durability and flexibility.

Regulatory Standards for VOC Content in Resins

Low-VOC resins comply with stringent regulatory standards set by agencies such as the EPA and CARB, which limit volatile organic compound content to reduce environmental and health impacts. High-VOC resins often exceed these limits, leading to increased emissions and stricter usage restrictions in many regions. Compliance with VOC regulations drives the demand for low-VOC resin formulations in applications like coatings, adhesives, and composites.

Sustainability Advantages of Low-VOC Resins

Low-VOC resin significantly reduces harmful emissions, promoting better indoor air quality and minimizing environmental pollution during production and application. Its sustainable composition often involves bio-based or recycled materials, enhancing resource efficiency and lowering carbon footprints compared to high-VOC alternatives. Regulatory compliance with stringent environmental standards further supports the adoption of low-VOC resins in eco-conscious manufacturing and construction projects.

Application Suitability: Choosing the Right Resin

Low-VOC resin is ideal for indoor applications or environments requiring minimal chemical emissions, ensuring better air quality and safety. High-VOC resin is suited for industrial or outdoor uses where rapid curing and strong adhesion are prioritized over emission concerns. Selecting the right resin depends on balancing application-specific performance needs with environmental and health considerations.

Future Trends in VOC Reduction for Resin Products

Low-VOC resin formulations are rapidly advancing, driven by stricter environmental regulations and growing consumer demand for eco-friendly materials in construction and manufacturing. Innovative catalyst technologies and bio-based feedstocks are emerging to further reduce VOC emissions while maintaining resin performance and durability. Future trends indicate a shift towards ultra-low and zero-VOC resin products, promoting healthier indoor air quality and minimizing environmental impact across various industrial applications.

Low-VOC Resin vs High-VOC Resin Infographic

materialdif.com

materialdif.com