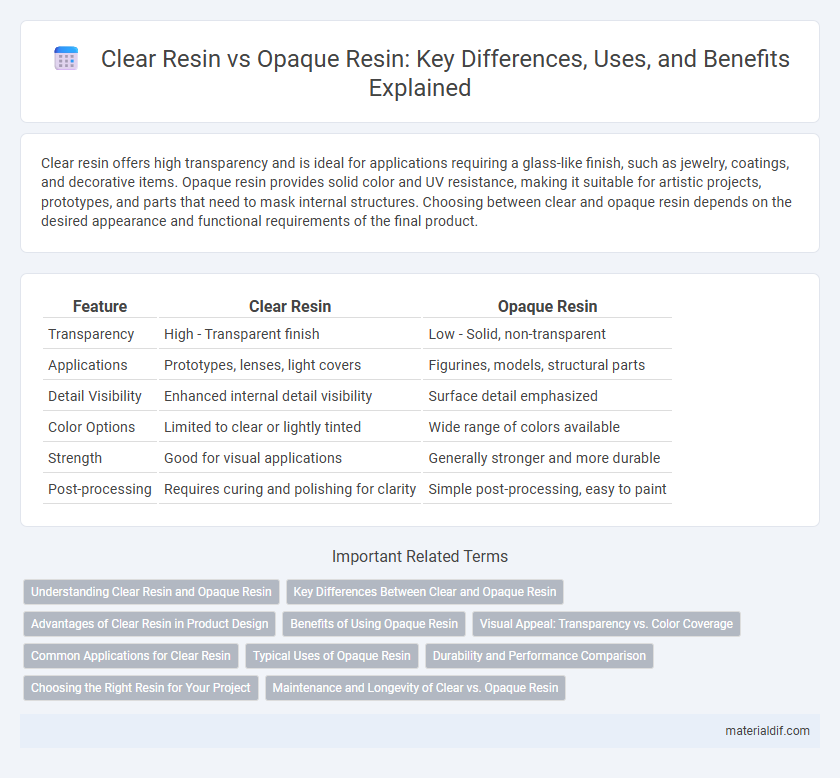

Clear resin offers high transparency and is ideal for applications requiring a glass-like finish, such as jewelry, coatings, and decorative items. Opaque resin provides solid color and UV resistance, making it suitable for artistic projects, prototypes, and parts that need to mask internal structures. Choosing between clear and opaque resin depends on the desired appearance and functional requirements of the final product.

Table of Comparison

| Feature | Clear Resin | Opaque Resin |

|---|---|---|

| Transparency | High - Transparent finish | Low - Solid, non-transparent |

| Applications | Prototypes, lenses, light covers | Figurines, models, structural parts |

| Detail Visibility | Enhanced internal detail visibility | Surface detail emphasized |

| Color Options | Limited to clear or lightly tinted | Wide range of colors available |

| Strength | Good for visual applications | Generally stronger and more durable |

| Post-processing | Requires curing and polishing for clarity | Simple post-processing, easy to paint |

Understanding Clear Resin and Opaque Resin

Clear resin offers transparency and high light transmission, making it ideal for applications requiring visual clarity such as jewelry, lenses, and display cases. Opaque resin provides solid coloration and better UV resistance, often used for parts requiring color consistency and durability like architectural models and figurines. Understanding the differences in clarity, light diffusion, and application suitability is crucial for selecting the right resin type for specific project needs.

Key Differences Between Clear and Opaque Resin

Clear resin offers high transparency, making it ideal for projects requiring light transmission and detailed visibility, while opaque resin provides solid color and hides internal structures, enhancing surface finish and consistency. Clear resin typically cures to a glossy, glass-like finish but can be prone to yellowing over time, whereas opaque resin maintains stable coloration with minimal light penetration and better UV resistance. Differences in formulation affect curing times, mechanical strength, and applications, with clear resin favored in jewelry and artistic pieces, and opaque resin preferred for prototyping and functional parts.

Advantages of Clear Resin in Product Design

Clear resin offers superior transparency, enabling intricate product details and internal components to be visibly showcased, enhancing aesthetic appeal and user understanding. Its optical clarity supports precise color customization, allowing designers to achieve vibrant, lifelike finishes unattainable with opaque resin. Additionally, clear resin facilitates lighting effects and transparency-based functionalities, expanding creative possibilities in innovative product design.

Benefits of Using Opaque Resin

Opaque resin offers superior UV resistance compared to clear resin, making it ideal for outdoor applications where prolonged sunlight exposure is expected. Its ability to hide imperfections and provide consistent color coverage enhances aesthetic quality in manufacturing and artistic projects. Opaque resin also improves material strength and durability, ensuring longer-lasting finished products in various industrial uses.

Visual Appeal: Transparency vs. Color Coverage

Clear resin offers superior transparency, allowing light to pass through and showcasing intricate details or embedded objects with vibrant clarity. Opaque resin, on the other hand, provides consistent color coverage that hides imperfections and creates bold, solid finishes ideal for decorative or artistic applications. Choosing between clear and opaque resin depends on whether the project prioritizes light transmission and depth or uniformity and vivid pigmentation.

Common Applications for Clear Resin

Clear resin is widely used in applications requiring transparency and optical clarity such as jewelry making, decorative objects, and protective coatings. It is favored for creating lenses, light covers, and artistic projects that showcase embedded materials with minimal distortion. Industries like electronics and automotive also utilize clear resin for encapsulating components and producing clear parts.

Typical Uses of Opaque Resin

Opaque resin is commonly used in applications requiring color precision and surface coverage, such as automotive parts, decorative items, and packaging materials. Its ability to mask underlying surfaces makes it ideal for creating solid-colored objects, toys, and household goods. Opaque resin also provides better UV resistance and durability, enhancing the longevity of outdoor products and industrial components.

Durability and Performance Comparison

Clear resin offers superior optical clarity and UV resistance, making it ideal for applications requiring transparency and long-term color stability. Opaque resin generally provides enhanced impact resistance and better concealment of defects, improving durability in rugged or load-bearing environments. Performance varies by resin formulation, with clear resin excelling in aesthetic applications and opaque resin favored for structural strength and wear resistance.

Choosing the Right Resin for Your Project

Clear resin offers high transparency and is ideal for projects requiring a glass-like finish or encapsulation of objects, while opaque resin provides solid color and better UV resistance for vibrant, durable finishes. When choosing the right resin, consider the project's aesthetic goals, light exposure, and desired durability. Clear resin suits artistic applications like jewelry and coatings, whereas opaque resin excels in decorative items and prototypes needing consistent color.

Maintenance and Longevity of Clear vs. Opaque Resin

Clear resin requires more meticulous maintenance to prevent yellowing and cloudiness caused by UV exposure and dust buildup, often needing regular polishing or UV protection coatings. Opaque resin typically offers greater longevity with less frequent upkeep since its solid pigments mask surface imperfections and discoloration. Both types benefit from proper cleaning and storage, but clear resin demands more attentive care to preserve its transparency over time.

Clear Resin vs Opaque Resin Infographic

materialdif.com

materialdif.com