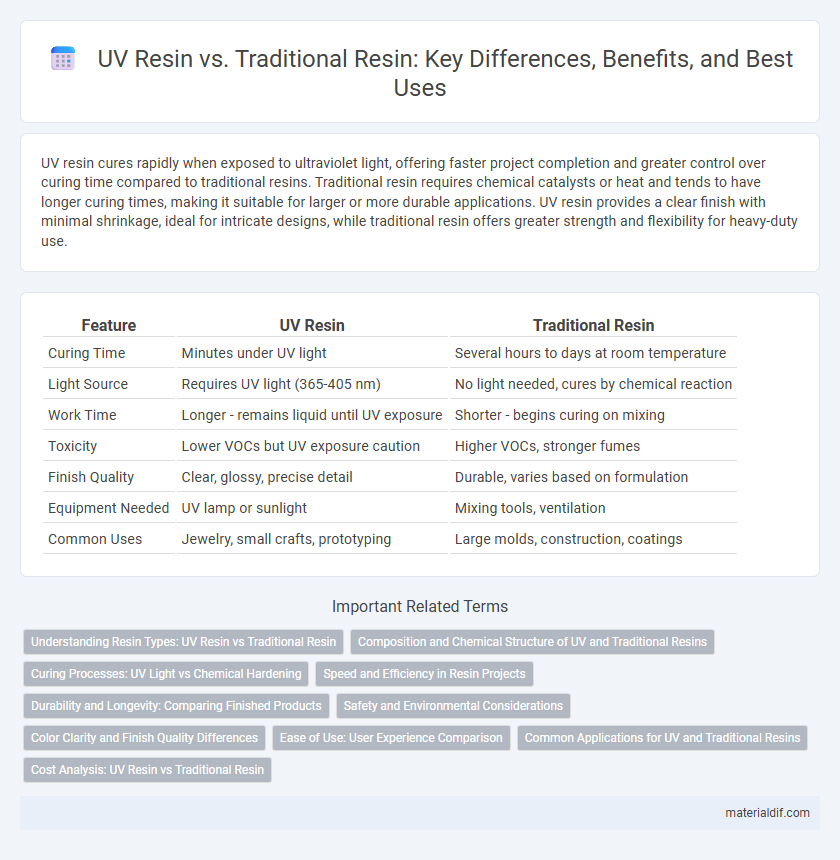

UV resin cures rapidly when exposed to ultraviolet light, offering faster project completion and greater control over curing time compared to traditional resins. Traditional resin requires chemical catalysts or heat and tends to have longer curing times, making it suitable for larger or more durable applications. UV resin provides a clear finish with minimal shrinkage, ideal for intricate designs, while traditional resin offers greater strength and flexibility for heavy-duty use.

Table of Comparison

| Feature | UV Resin | Traditional Resin |

|---|---|---|

| Curing Time | Minutes under UV light | Several hours to days at room temperature |

| Light Source | Requires UV light (365-405 nm) | No light needed, cures by chemical reaction |

| Work Time | Longer - remains liquid until UV exposure | Shorter - begins curing on mixing |

| Toxicity | Lower VOCs but UV exposure caution | Higher VOCs, stronger fumes |

| Finish Quality | Clear, glossy, precise detail | Durable, varies based on formulation |

| Equipment Needed | UV lamp or sunlight | Mixing tools, ventilation |

| Common Uses | Jewelry, small crafts, prototyping | Large molds, construction, coatings |

Understanding Resin Types: UV Resin vs Traditional Resin

UV resin cures quickly under ultraviolet light, offering precision and reduced curing time ideal for small-scale projects and intricate details. Traditional resin relies on chemical curing agents, typically requiring longer curing periods and providing robust strength for larger molds and applications. Selecting between UV and traditional resin depends on project size, detail complexity, and desired curing speed.

Composition and Chemical Structure of UV and Traditional Resins

UV resin consists primarily of oligomers and monomers such as acrylates and methacrylates that polymerize instantly under ultraviolet light due to photoinitiators, enabling rapid curing. Traditional resin, often epoxy-based or polyester, involves a two-component chemical reaction between resin and hardener that cures via a slower, heat- or time-dependent polymerization process. The chemical structure of UV resin is designed for fast cross-linking with reactive double bonds, while traditional resins form three-dimensional networks through exothermic curing reactions, resulting in differences in mechanical properties and application methods.

Curing Processes: UV Light vs Chemical Hardening

UV resin cures quickly under UV light, enabling precise control over curing time and reducing overall project duration. Traditional resin relies on chemical hardening through a catalyst or hardener, which requires longer curing periods and can be affected by temperature and humidity variations. UV curing offers faster processing speeds and less environmental sensitivity compared to the slower, variable chemical hardening method of traditional resin.

Speed and Efficiency in Resin Projects

UV resin cures within minutes under UV light, significantly accelerating project completion compared to traditional resin, which requires several hours to days to fully harden through chemical reaction. This rapid curing process enhances efficiency by allowing for quick layering and reduced waiting times, ideal for time-sensitive and intricate resin projects. Traditional resin, while slower, offers longer working time for detailed adjustments but compromises overall speed and productivity.

Durability and Longevity: Comparing Finished Products

UV resin cures quickly under ultraviolet light, resulting in finished products with superior durability and resistance to yellowing compared to traditional resin, which cures more slowly through chemical reactions. Traditional resin often offers greater flexibility and impact resistance but may be more prone to cracking or degradation over time when exposed to UV light and environmental factors. Overall, UV resin products tend to maintain their clarity and structural integrity longer, making them ideal for applications requiring long-lasting, robust finishes.

Safety and Environmental Considerations

UV resin cures quickly under ultraviolet light, reducing exposure to harmful fumes compared to traditional resin that often requires longer curing times and emits stronger volatile organic compounds (VOCs). UV resin formulations tend to contain fewer harmful chemicals, making them safer to handle with minimal protective gear, whereas traditional resins often demand extensive safety measures such as gloves, masks, and adequate ventilation. Environmentally, UV resins generate less waste due to faster curing and reduced chemical runoff, while traditional resins pose greater environmental risks through higher VOC emissions and non-biodegradable waste.

Color Clarity and Finish Quality Differences

UV resin cures rapidly under ultraviolet light, offering superior color clarity and a crystal-clear finish compared to traditional resin, which often has a slight yellow tint and requires longer curing times. The fast curing process in UV resin minimizes bubbles and imperfections, resulting in a smoother, glossier surface ideal for detailed crafts and jewelry. Traditional resin, while versatile, may produce a less transparent finish and requires careful mixing and curing conditions to achieve comparable clarity and finish quality.

Ease of Use: User Experience Comparison

UV resin offers a significantly faster curing process, hardening within minutes under UV light, which enhances user convenience and reduces wait times compared to traditional resin that can take hours to cure. Its low viscosity allows for easier application and less mess, improving precision in detailed projects. Traditional resin requires careful mixing and longer curing periods, which may lead to increased complexity and user errors during handling.

Common Applications for UV and Traditional Resins

UV resin is ideal for small-scale crafts, jewelry making, and rapid prototyping due to its quick curing time under ultraviolet light. Traditional resin excels in large-scale projects such as boat building, countertop fabrication, and casting complex molds because of its longer working time and superior strength. Both resins are widely used in art, industrial applications, and DIY projects, chosen based on curing speed, durability, and application size requirements.

Cost Analysis: UV Resin vs Traditional Resin

UV resin typically incurs higher initial costs due to the requirement of specialized curing lamps and equipment, while traditional resin remains more affordable for large-scale projects with its simpler application process. Despite a higher price per ounce, UV resin offers faster curing times, reducing overall labor expenses compared to the longer curing cycle of traditional resin. When analyzing the total cost of ownership, traditional resin often proves more cost-effective for bulk applications, whereas UV resin excels in precision work with smaller quantities.

UV Resin vs Traditional Resin Infographic

materialdif.com

materialdif.com