Laminating resin provides excellent adhesion and clarity, making it ideal for hand lay-up and brush applications in composite construction. Infusion resin offers superior flow characteristics and low viscosity, ensuring even fiber wet-out and strong, void-free laminates in vacuum-assisted resin transfer molding (VARTM). Choosing between laminating and infusion resin depends on the specific manufacturing process and performance requirements of the composite part.

Table of Comparison

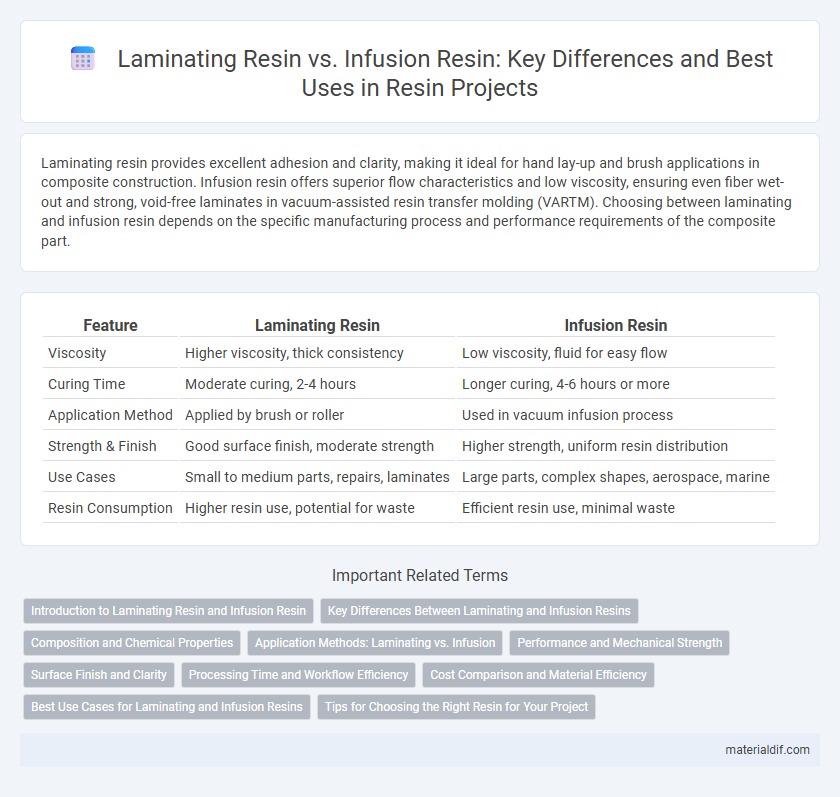

| Feature | Laminating Resin | Infusion Resin |

|---|---|---|

| Viscosity | Higher viscosity, thick consistency | Low viscosity, fluid for easy flow |

| Curing Time | Moderate curing, 2-4 hours | Longer curing, 4-6 hours or more |

| Application Method | Applied by brush or roller | Used in vacuum infusion process |

| Strength & Finish | Good surface finish, moderate strength | Higher strength, uniform resin distribution |

| Use Cases | Small to medium parts, repairs, laminates | Large parts, complex shapes, aerospace, marine |

| Resin Consumption | Higher resin use, potential for waste | Efficient resin use, minimal waste |

Introduction to Laminating Resin and Infusion Resin

Laminating resin is a polyester or epoxy-based material designed for hand lay-up and wet lay-up techniques, providing strong adhesion and durability in composite manufacturing. Infusion resin, typically epoxy or polyester, is formulated for vacuum infusion processes, offering low viscosity to thoroughly saturate fiber reinforcements and reduce voids. Both resins play crucial roles in producing lightweight, high-strength composite structures used in marine, automotive, and aerospace industries.

Key Differences Between Laminating and Infusion Resins

Laminating resin, typically polyester or epoxy-based, is designed for manual application through layering with fiberglass cloth, offering ease of use and faster curing times for small-scale projects. Infusion resin, usually a low-viscosity epoxy, enables vacuum-assisted resin transfer, providing superior fiber wet-out, reduced voids, and stronger, lighter composite parts for industrial applications. The key differences lie in application methods, resin viscosity, cure control, and resultant composite quality, with infusion resin favored for high-performance and large-scale manufacturing.

Composition and Chemical Properties

Laminating resin typically consists of polyester or vinyl ester polymers with moderate viscosity, enabling easy application with brushes or rollers, and it cures through a free-radical polymerization mechanism initiated by benzoyl peroxide. Infusion resin, often epoxy-based, has lower viscosity for better fiber wetting and improved mechanical properties, curing via a chemical reaction between epoxy groups and hardeners like amines. The chemical structure of infusion resin allows higher resistance to moisture and heat, whereas laminating resin's composition offers faster curing times and simpler processing for general composite fabrication.

Application Methods: Laminating vs. Infusion

Laminating resin is applied by hand-laying resin onto dry reinforcement materials using brushes or rollers, making it suitable for smaller or more intricate projects with precise control. Infusion resin is used in vacuum infusion processes where resin is drawn into the fibers under vacuum pressure, ensuring thorough saturation and reducing voids for larger, high-performance composites. The infusion method offers improved fiber-to-resin ratios and enhanced structural integrity compared to manual laminating techniques.

Performance and Mechanical Strength

Laminating resin typically offers high mechanical strength and excellent adhesion properties, making it ideal for applications requiring robust structural integrity and durability. Infusion resin, on the other hand, provides superior performance in achieving a high fiber-to-resin ratio and enhanced laminate quality due to its low viscosity, resulting in lighter and stronger composite parts. Both resins deliver strong mechanical performance, but infusion resin excels in producing consistent void-free laminates with improved strength-to-weight ratios.

Surface Finish and Clarity

Laminating resin offers a high-gloss surface finish with excellent clarity, making it ideal for visible, decorative applications where aesthetics are crucial. Infusion resin, by contrast, often yields a more uniform and bubble-free surface due to controlled vacuum processes, enhancing clarity and smoothness in structural composite manufacturing. Selecting between laminating and infusion resin depends on balancing surface finish quality with processing requirements for optimal clarity and performance.

Processing Time and Workflow Efficiency

Laminating resin offers faster curing times, enabling quicker layer application which enhances workflow efficiency for projects requiring rapid turnaround. Infusion resin, while typically slower to cure, provides superior fiber wet-out and reduced voids, optimizing structural integrity but demanding more extended processing times. Selecting between laminating and infusion resins depends on balancing the need for processing speed against the desired mechanical performance and production workflow.

Cost Comparison and Material Efficiency

Laminating resin generally costs less upfront but requires more material and labor due to higher resin consumption and potential waste during hand lay-up processes. Infusion resin, while initially pricier, offers superior material efficiency by optimizing resin usage through vacuum infusion, reducing excess resin and improving fiber-to-resin ratios. The cost difference balances out over time as infusion resin minimizes waste and labor expenses, making it a cost-effective choice for high-quality composite production.

Best Use Cases for Laminating and Infusion Resins

Laminating resin is best suited for hand lay-up and spray-up techniques in applications requiring strong adhesion and high mechanical strength, such as marine hulls and automotive body panels. Infusion resin excels in vacuum-assisted resin transfer molding (VARTM), enabling precise control over resin flow and minimizing voids, making it ideal for large structures like wind turbine blades and aerospace components. Both resins serve distinct purposes, with laminating resin prioritizing ease of use and rapid curing, while infusion resin offers superior fiber wet-out and reduced emissions.

Tips for Choosing the Right Resin for Your Project

Laminating resin offers superior viscosity control and is ideal for hand lay-up techniques, providing excellent wet-out for fabrics and smooth finishes, while infusion resin is low-viscosity, designed for vacuum infusion processes to ensure thorough fiber saturation and reduced voids. Choose laminating resin for projects requiring precise layering and surface quality, and opt for infusion resin when seeking high strength-to-weight ratios and consistent resin distribution in complex molds. Consider project size, desired mechanical properties, curing time, and compatibility with reinforcement materials to select the resin that maximizes performance and efficiency.

Laminating Resin vs Infusion Resin Infographic

materialdif.com

materialdif.com