Pigmented resin offers vibrant, solid colors ideal for creating opaque, detailed models, enhancing visual impact without additional painting. Clear resin enables transparency and light diffusion, perfect for parts requiring see-through effects or internal detail visibility. Choosing between pigmented and clear resin depends on the desired aesthetic and functional properties of the final 3D printed object.

Table of Comparison

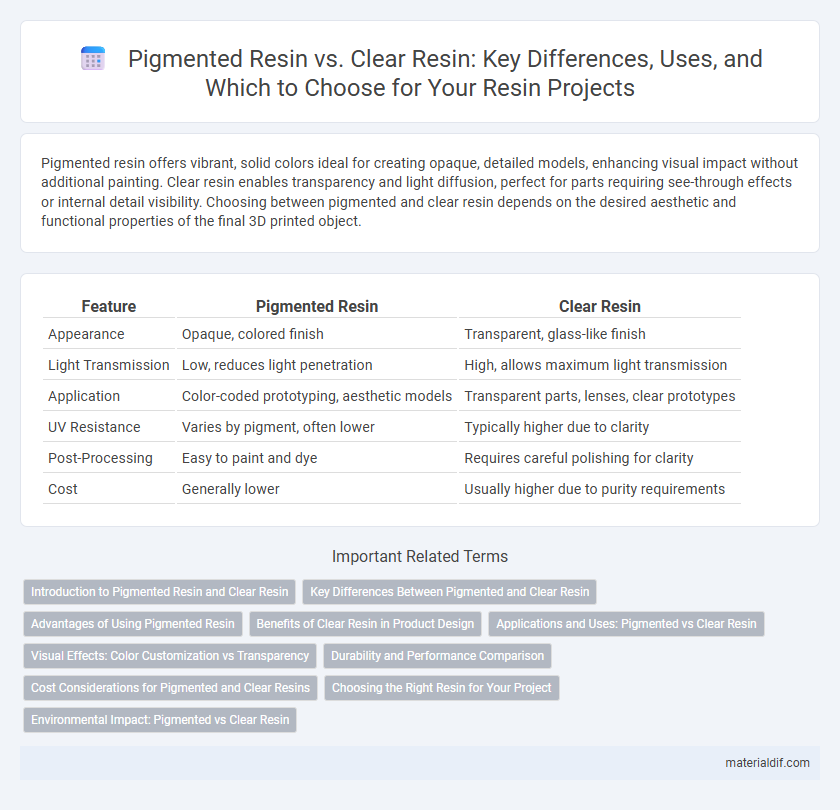

| Feature | Pigmented Resin | Clear Resin |

|---|---|---|

| Appearance | Opaque, colored finish | Transparent, glass-like finish |

| Light Transmission | Low, reduces light penetration | High, allows maximum light transmission |

| Application | Color-coded prototyping, aesthetic models | Transparent parts, lenses, clear prototypes |

| UV Resistance | Varies by pigment, often lower | Typically higher due to clarity |

| Post-Processing | Easy to paint and dye | Requires careful polishing for clarity |

| Cost | Generally lower | Usually higher due to purity requirements |

Introduction to Pigmented Resin and Clear Resin

Pigmented resin contains added colorants that provide opacity and vibrant hues, making it ideal for decorative applications and parts requiring color consistency. Clear resin offers transparency, allowing light to pass through, which is perfect for creating see-through prototypes, jewelry, and optical components. Both types are used in 3D printing and casting, with choice dependent on whether color vibrancy or translucency is desired.

Key Differences Between Pigmented and Clear Resin

Pigmented resin contains color additives that provide opacity and vibrancy, making it ideal for decorative projects and color-specific applications, whereas clear resin offers transparency and clarity, allowing underlying materials or inclusions to remain visible. The chemical composition of pigmented resin often includes color pigments or dyes that may slightly affect curing time and hardness, unlike clear resin which cures to a pristine, glass-like finish. Clear resin is preferable for encapsulation and artistic uses where visibility is essential, while pigmented resin excels in coloring effects and masking surfaces.

Advantages of Using Pigmented Resin

Pigmented resin offers enhanced UV resistance, reducing yellowing and degradation over time compared to clear resin, making it ideal for outdoor applications. It provides excellent opacity and color consistency, which improves aesthetic appeal and allows for precise color matching in manufacturing. Furthermore, pigmented resin can mask imperfections and contaminants within the material, resulting in a higher-quality final product.

Benefits of Clear Resin in Product Design

Clear resin offers exceptional transparency that allows designers to showcase intricate internal details and achieve a sleek, modern aesthetic in product design. Its ability to transmit light enhances visual depth and realism, making it ideal for prototypes, decorative items, and transparent components. Furthermore, clear resin provides versatility in finishing options, enabling customization with dyes or coatings while maintaining clarity and durability.

Applications and Uses: Pigmented vs Clear Resin

Pigmented resin is ideal for applications requiring vibrant colors and opacity, such as decorative objects, automotive parts, and consumer electronics housings, where color consistency and UV resistance are critical. Clear resin is preferred for uses demanding transparency and light transmission, including optical lenses, medical devices, and prototyping of clear components, offering excellent clarity and high detail resolution. Both types are used in 3D printing, but pigmented resin excels in aesthetic-focused products, while clear resin is chosen for functional prototypes needing visual inspection.

Visual Effects: Color Customization vs Transparency

Pigmented resin offers extensive color customization, enabling precise visual effects and vibrant, opaque finishes ideal for artistic or decorative projects. Clear resin provides unparalleled transparency, showcasing embedded objects or layers with crystal-clear clarity and depth, making it perfect for jewelry or resin art where light transmission enhances the design. Choosing between pigmented and clear resin depends on whether color vibrancy or optical transparency is prioritized for the final visual impact.

Durability and Performance Comparison

Pigmented resin offers enhanced UV resistance and scratch durability compared to clear resin, making it ideal for outdoor applications and products requiring long-term performance. Clear resin, while providing superior optical clarity and aesthetic appeal, tends to be more susceptible to yellowing and surface wear over time. Choosing between pigmented and clear resin depends on whether durability against environmental factors or transparent finish is the primary performance requirement.

Cost Considerations for Pigmented and Clear Resins

Pigmented resin typically costs more than clear resin due to the additional manufacturing processes and raw materials required for color formulation and consistency. Clear resin offers a more economical option for projects where transparency is desired, reducing expenses related to pigments and color additives. Budget planning should account for the cost differences, especially in large-scale or color-critical resin applications.

Choosing the Right Resin for Your Project

Pigmented resin offers vibrant, customizable colors ideal for artistic projects requiring specific hues or opacity, while clear resin provides transparency, perfect for encapsulating objects or achieving a glass-like finish. Selecting the right resin depends on the desired aesthetic and functional properties, such as UV resistance, curing time, and durability. Understanding the project's requirements ensures optimal material performance and the best visual outcome.

Environmental Impact: Pigmented vs Clear Resin

Pigmented resin often contains additional colorants and additives that can increase its environmental footprint compared to clear resin, which typically has fewer chemical components. The production and disposal of pigmented resin may contribute to higher levels of toxic waste and microplastic pollution due to the presence of synthetic dyes. Clear resin, while still impactful, generally exhibits a lower environmental impact because it requires fewer processing steps and contains fewer potentially harmful substances.

Pigmented Resin vs Clear Resin Infographic

materialdif.com

materialdif.com