Cationic resins carry positively charged functional groups that attract and exchange negatively charged ions, making them ideal for removing anions like sulfate and nitrate from solutions. Anionic resins, by contrast, have negatively charged sites that preferentially bind and replace cations such as calcium, magnesium, and heavy metals. Selecting between cationic and anionic resins depends on the specific ionic contaminants targeted for removal in water treatment or chemical processing applications.

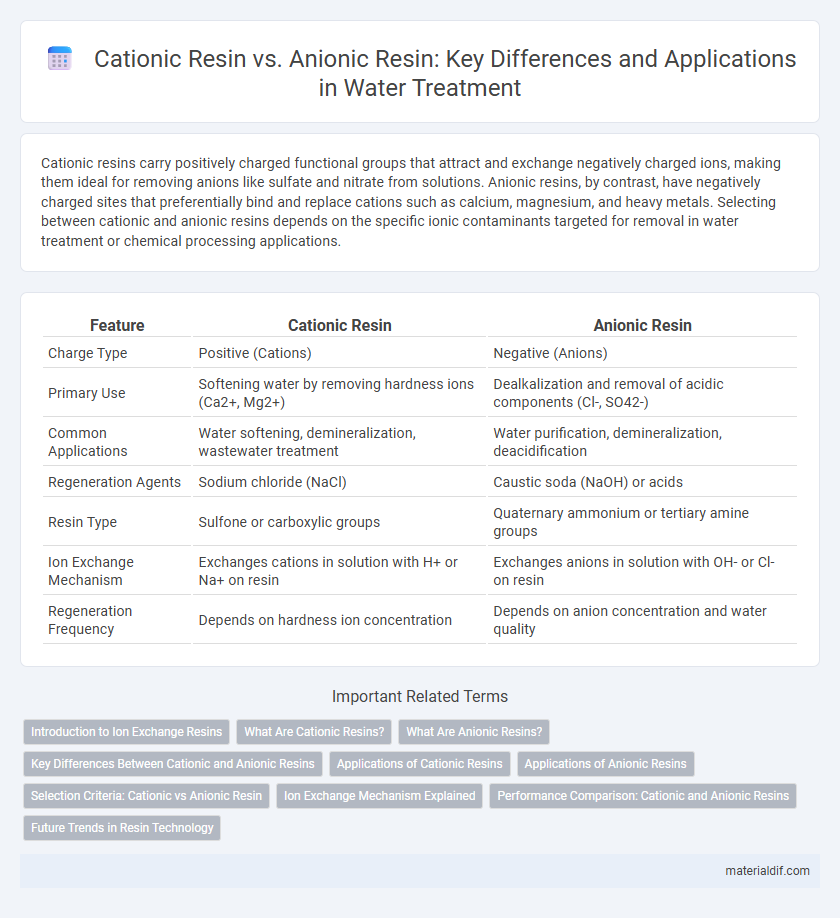

Table of Comparison

| Feature | Cationic Resin | Anionic Resin |

|---|---|---|

| Charge Type | Positive (Cations) | Negative (Anions) |

| Primary Use | Softening water by removing hardness ions (Ca2+, Mg2+) | Dealkalization and removal of acidic components (Cl-, SO42-) |

| Common Applications | Water softening, demineralization, wastewater treatment | Water purification, demineralization, deacidification |

| Regeneration Agents | Sodium chloride (NaCl) | Caustic soda (NaOH) or acids |

| Resin Type | Sulfone or carboxylic groups | Quaternary ammonium or tertiary amine groups |

| Ion Exchange Mechanism | Exchanges cations in solution with H+ or Na+ on resin | Exchanges anions in solution with OH- or Cl- on resin |

| Regeneration Frequency | Depends on hardness ion concentration | Depends on anion concentration and water quality |

Introduction to Ion Exchange Resins

Ion exchange resins are synthetic polymers used to exchange specific ions within a solution, enabling purification, separation, and decontamination processes. Cationic resins exchange positively charged ions like calcium and magnesium, commonly used in water softening, while anionic resins target negatively charged ions such as chloride and sulfate, essential for removing contaminants and organic acids. The choice between cationic and anionic resins depends on the specific ion removal requirements and the chemical nature of the treated solution.

What Are Cationic Resins?

Cationic resins are polymer materials with positively charged functional groups designed to attract and exchange negatively charged ions or anions in water treatment and purification processes. These resins are commonly used for softening hard water by replacing calcium and magnesium ions with sodium or hydrogen ions through ion exchange mechanisms. Their efficiency in removing anions like nitrates, sulfates, and organic acids makes cationic resins essential in applications ranging from industrial wastewater treatment to household water softening systems.

What Are Anionic Resins?

Anionic resins are synthetic polymers containing negatively charged functional groups that attract and exchange positively charged ions (cations) in water treatment and purification processes. These resins are widely used for water softening, metal recovery, and deionization by selectively binding to cations such as calcium, magnesium, and heavy metals. Their high ion-exchange capacity and stability make anionic resins essential for industrial applications requiring efficient removal of undesirable cations from aqueous solutions.

Key Differences Between Cationic and Anionic Resins

Cationic resins contain positively charged functional groups that attract and exchange negatively charged ions, making them ideal for applications like water softening and heavy metal removal. Anionic resins have negatively charged functional groups, which enable them to capture and exchange positively charged ions, commonly used for nitrate removal and deacidification processes. Key differences include their charge type, targeted ion species, and specific applications in ion exchange and purification systems.

Applications of Cationic Resins

Cationic resins are primarily used in water treatment processes to remove hardness ions like calcium and magnesium by exchanging them with sodium ions, enhancing water quality for industrial and residential use. These resins are also essential in the purification of pharmaceuticals and food products, where they selectively bind with negatively charged impurities, improving product safety and efficacy. In the paper and textile industries, cationic resins facilitate dye fixation and improve the retention of additives, contributing to better product durability and appearance.

Applications of Anionic Resins

Anionic resins are widely used in water treatment processes, particularly for deionization and softening applications where they effectively remove negatively charged ions like sulfate, nitrate, and bicarbonate. These resins play a crucial role in industrial wastewater treatment, pharmaceutical purification, and food and beverage processing by selectively adsorbing anions to improve water quality. Their application extends to the regeneration of catalysts and separation processes in chemical manufacturing, highlighting their versatility in removing contaminants and purifying solutions.

Selection Criteria: Cationic vs Anionic Resin

Selection criteria for cationic versus anionic resin primarily depend on the type of ionic contaminants targeted for removal; cationic resins are optimal for eliminating positively charged ions such as calcium, magnesium, and heavy metals, while anionic resins effectively remove negatively charged ions like chloride, sulfate, and nitrate. Water pH, resin capacity, and regeneration efficiency also play crucial roles in determining the appropriate resin type for processes like water softening, deionization, or wastewater treatment. Understanding the specific ionic composition and treatment goals ensures accurate resin selection, maximizing purification efficiency and operational lifespan.

Ion Exchange Mechanism Explained

Cationic resins operate through ion exchange by replacing positively charged ions in a solution with hydrogen or sodium ions attached to sulfonic acid groups on the resin matrix. Anionic resins function by exchanging negatively charged ions in the solution with hydroxide ions bound to quaternary ammonium groups on the resin surface. The ion exchange mechanism in both resins involves reversible adsorption and desorption processes, enabling selective removal or recovery of specific ions based on charge type and affinity.

Performance Comparison: Cationic and Anionic Resins

Cationic resins exhibit superior performance in removing negatively charged contaminants such as heavy metals and organic acids due to their positively charged functional groups, making them highly effective in water softening and purification processes. Anionic resins, possessing negatively charged sites, excel in capturing positively charged ions like ammonia and certain heavy metals, often demonstrating higher selectivity in alkaline conditions. The choice between cationic and anionic resins depends on the specific application requirements, including ion exchange capacity, regeneration efficiency, and the nature of target ions in the treatment system.

Future Trends in Resin Technology

Future trends in resin technology emphasize enhancing the selectivity and capacity of cationic and anionic resins through advanced functional group modifications and nano-scale structural engineering. Innovations in hybrid resin systems integrate both cationic and anionic properties to optimize ion exchange efficiency for water treatment and industrial applications. Research focuses on increasing resin durability and regeneration cycles, driven by demands for sustainable and cost-effective ion exchange solutions.

Cationic Resin vs Anionic Resin Infographic

materialdif.com

materialdif.com