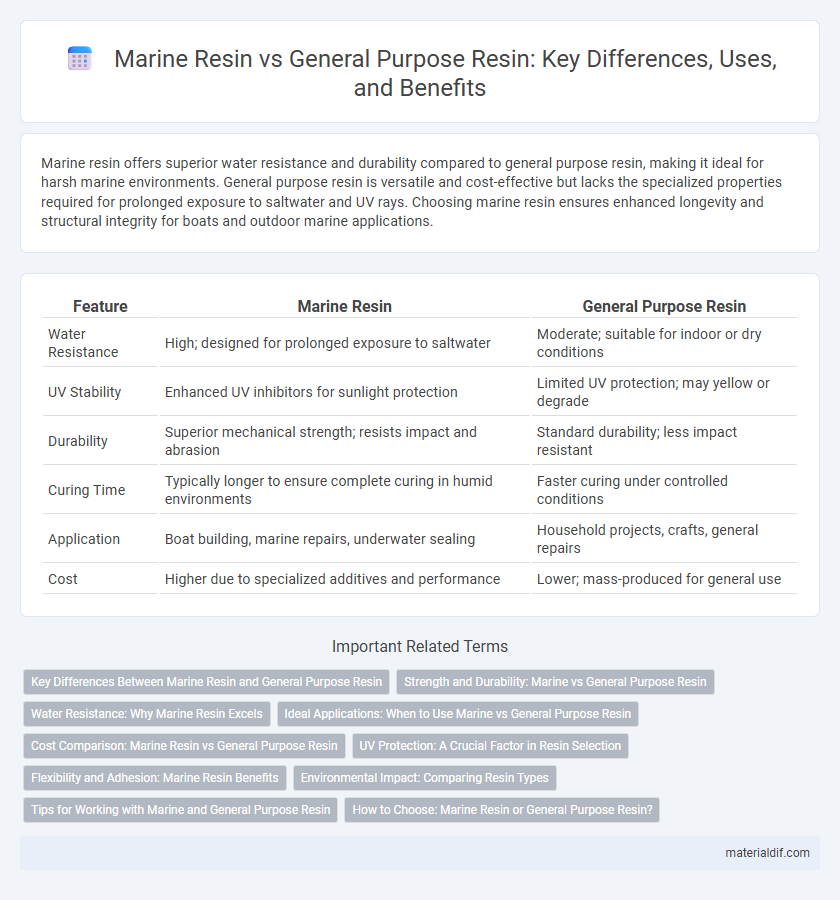

Marine resin offers superior water resistance and durability compared to general purpose resin, making it ideal for harsh marine environments. General purpose resin is versatile and cost-effective but lacks the specialized properties required for prolonged exposure to saltwater and UV rays. Choosing marine resin ensures enhanced longevity and structural integrity for boats and outdoor marine applications.

Table of Comparison

| Feature | Marine Resin | General Purpose Resin |

|---|---|---|

| Water Resistance | High; designed for prolonged exposure to saltwater | Moderate; suitable for indoor or dry conditions |

| UV Stability | Enhanced UV inhibitors for sunlight protection | Limited UV protection; may yellow or degrade |

| Durability | Superior mechanical strength; resists impact and abrasion | Standard durability; less impact resistant |

| Curing Time | Typically longer to ensure complete curing in humid environments | Faster curing under controlled conditions |

| Application | Boat building, marine repairs, underwater sealing | Household projects, crafts, general repairs |

| Cost | Higher due to specialized additives and performance | Lower; mass-produced for general use |

Key Differences Between Marine Resin and General Purpose Resin

Marine resin is specifically formulated to withstand harsh aquatic environments, offering superior water resistance, UV stability, and flexibility compared to general purpose resin. General purpose resin is designed for a wide range of applications but lacks the enhanced durability and corrosion resistance required for prolonged marine exposure. The key differences lie in marine resin's chemical additives and curing agents that prevent degradation from saltwater, moisture, and sunlight, ensuring longevity in marine vessels, while general purpose resin prioritizes versatility over specialized protection.

Strength and Durability: Marine vs General Purpose Resin

Marine resin offers superior strength and durability compared to general purpose resin, specifically formulated to withstand harsh marine environments, including saltwater exposure and constant moisture. Its enhanced resistance to UV degradation, osmotic blistering, and hydrolysis ensures long-lasting performance in boats and marine structures. General purpose resin, while versatile, lacks the specialized additives and formulations that provide the critical toughness and longevity required for marine applications.

Water Resistance: Why Marine Resin Excels

Marine resin offers superior water resistance compared to general-purpose resin due to its specially formulated epoxy compounds designed to withstand prolonged exposure to moisture and saltwater. Its enhanced durability and resistance to hydrolysis prevent degradation, ensuring long-lasting protection in marine environments. This makes marine resin the optimal choice for boat building, repairs, and underwater applications where water resistance is critical.

Ideal Applications: When to Use Marine vs General Purpose Resin

Marine resin is specifically formulated for harsh, saline environments, making it ideal for boat building, repair, and other marine applications requiring high water resistance and durability. General purpose resin suits everyday projects like household repairs, crafting, and light structural bonding where exposure to moisture and extreme conditions is minimal. Choosing marine resin ensures superior performance in aquatic settings, while general purpose resin offers cost-effective versatility for standard uses.

Cost Comparison: Marine Resin vs General Purpose Resin

Marine resin typically costs 20-30% more than general purpose resin due to its enhanced properties like superior water resistance and UV stability, which are critical for marine applications. General purpose resin is less expensive but lacks the specialized durability required for prolonged exposure to harsh marine environments. The higher initial investment in marine resin often results in longer-term savings by reducing maintenance and replacement costs in seawater conditions.

UV Protection: A Crucial Factor in Resin Selection

Marine resin offers superior UV protection compared to general purpose resin, making it ideal for prolonged exposure to sunlight and harsh marine environments. Its enhanced ultraviolet inhibitors prevent yellowing and degradation, ensuring longer-lasting clarity and structural integrity. In contrast, general purpose resin may deteriorate faster under UV rays, leading to diminished durability and compromised aesthetic appeal over time.

Flexibility and Adhesion: Marine Resin Benefits

Marine resin offers superior flexibility and adhesion compared to general purpose resin, making it ideal for harsh aquatic environments. Its formulation accommodates structural movements and resists cracking under stress, enhancing durability in marine applications. Enhanced adhesion properties ensure strong bonding to diverse substrates such as wood, fiberglass, and metal, preventing water infiltration and prolonging the lifespan of marine structures.

Environmental Impact: Comparing Resin Types

Marine resin is formulated with higher durability and resistance to saltwater corrosion, reducing the frequency of repairs and replacements, which lowers overall environmental waste. General purpose resin often requires more frequent maintenance and replacements due to lower resilience in harsh marine environments, leading to increased environmental impact through material consumption and disposal. The eco-friendly advantage of marine resin lies in its enhanced longevity and reduced need for chemical treatments, minimizing pollution in sensitive aquatic ecosystems.

Tips for Working with Marine and General Purpose Resin

When working with marine resin, ensure optimal curing by maintaining a stable temperature between 70-80degF and using proper gel coat primers for UV resistance. For general purpose resin, focus on thorough surface preparation and accurate resin-to-hardener ratios to prevent imperfections and achieve strong adhesion. Both types benefit from using quality brushes and rollers to minimize air bubbles and achieve smooth finishes.

How to Choose: Marine Resin or General Purpose Resin?

Selecting between marine resin and general-purpose resin depends on application-specific requirements such as exposure to water, UV resistance, and mechanical strength. Marine resin is formulated with enhanced water resistance, corrosion protection, and superior adhesion for harsh maritime environments, making it ideal for boat repairs and underwater applications. General-purpose resin offers versatility and cost-effectiveness suitable for indoor or dry environments but lacks the durability features essential for prolonged marine exposure.

Marine Resin vs General Purpose Resin Infographic

materialdif.com

materialdif.com