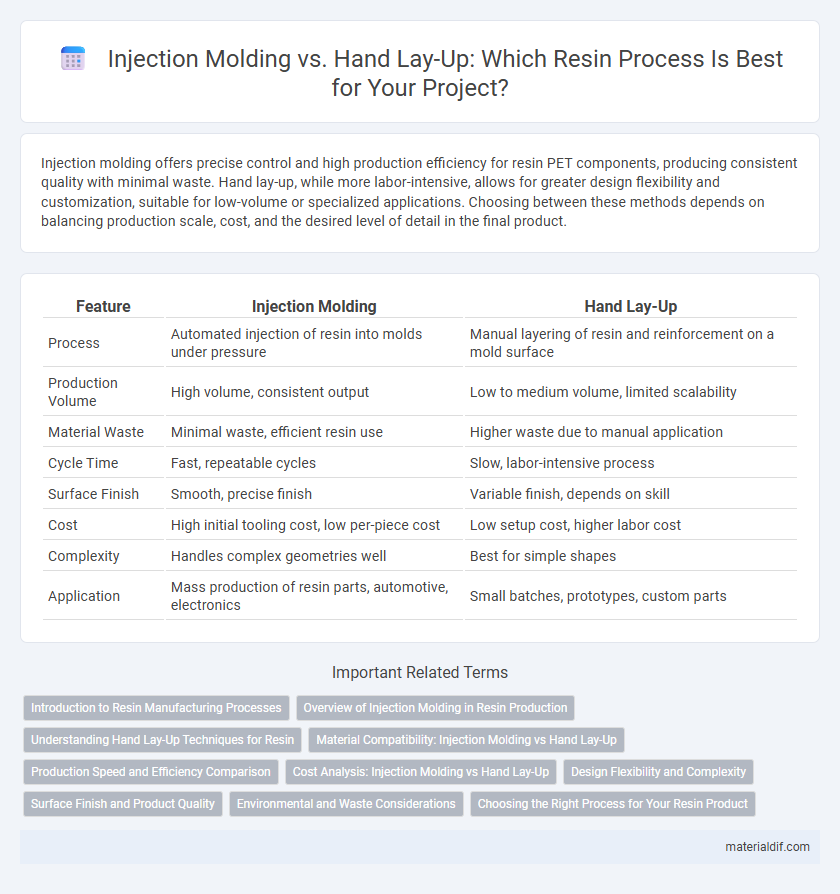

Injection molding offers precise control and high production efficiency for resin PET components, producing consistent quality with minimal waste. Hand lay-up, while more labor-intensive, allows for greater design flexibility and customization, suitable for low-volume or specialized applications. Choosing between these methods depends on balancing production scale, cost, and the desired level of detail in the final product.

Table of Comparison

| Feature | Injection Molding | Hand Lay-Up |

|---|---|---|

| Process | Automated injection of resin into molds under pressure | Manual layering of resin and reinforcement on a mold surface |

| Production Volume | High volume, consistent output | Low to medium volume, limited scalability |

| Material Waste | Minimal waste, efficient resin use | Higher waste due to manual application |

| Cycle Time | Fast, repeatable cycles | Slow, labor-intensive process |

| Surface Finish | Smooth, precise finish | Variable finish, depends on skill |

| Cost | High initial tooling cost, low per-piece cost | Low setup cost, higher labor cost |

| Complexity | Handles complex geometries well | Best for simple shapes |

| Application | Mass production of resin parts, automotive, electronics | Small batches, prototypes, custom parts |

Introduction to Resin Manufacturing Processes

Injection molding uses heated resin injected into molds under high pressure, producing precise, consistent parts ideal for high-volume manufacturing. Hand lay-up involves manually applying resin and reinforcement layers onto molds, offering flexibility for low-volume or large, complex shapes. Both processes utilize thermosetting or thermoplastic resins but differ significantly in automation, production speed, and dimensional accuracy.

Overview of Injection Molding in Resin Production

Injection molding in resin production involves injecting molten resin into precision-engineered molds under high pressure, enabling the creation of complex and high-strength components with excellent repeatability. This method is highly efficient for mass production, delivering consistent part quality and reduced material waste compared to hand lay-up processes. The ability to automate injection molding significantly lowers labor costs and cycle times, making it ideal for large-scale manufacturing of resin-based products.

Understanding Hand Lay-Up Techniques for Resin

Hand lay-up techniques for resin involve manually applying layers of resin and reinforcing fibers onto a mold surface, allowing precise control over resin distribution and fiber orientation. This method requires careful timing and layering to ensure optimal curing and strength, particularly critical in composites used for automotive, marine, and aerospace components. Compared to injection molding, hand lay-up is more versatile for large or complex shapes but demands skilled labor and longer production times.

Material Compatibility: Injection Molding vs Hand Lay-Up

Injection molding excels with thermoplastic resins like polyethylene and polypropylene, offering precise control and high production efficiency, whereas hand lay-up is suited for thermoset resins such as epoxy and polyester that require manual layering and curing. Injection molding demands materials with specific melt flow characteristics to fill molds effectively, while hand lay-up accommodates a broader range of resin viscosities and fiber reinforcements for customized composite structures. Material compatibility in injection molding favors uniformity and repeatability, while hand lay-up allows greater flexibility in resin selection for complex shapes and repairs.

Production Speed and Efficiency Comparison

Injection molding offers significantly higher production speed and efficiency compared to hand lay-up, producing complex resin parts in minutes with minimal labor. The automated process ensures consistent quality and reduces material waste, enhancing overall productivity. Hand lay-up remains slower and labor-intensive, making it less suitable for high-volume manufacturing.

Cost Analysis: Injection Molding vs Hand Lay-Up

Injection molding offers higher upfront costs due to expensive molds but achieves lower per-unit expenses in large production runs, making it cost-effective for mass manufacturing. Hand lay-up incurs minimal initial investment with basic tools and molds, but higher labor costs and longer production times increase expenses for large volumes. Analyzing cost efficiency depends on production scale, with injection molding favored for high-volume output and hand lay-up preferred for low-volume or custom parts.

Design Flexibility and Complexity

Injection molding offers high design flexibility and supports complex geometries with precise details due to the use of computer-aided design (CAD) and automated processes. Hand lay-up is limited in design complexity, as it relies on manual application of resin and reinforcement, making intricate shapes and tight tolerances challenging. For mass production requiring consistent quality and complex components, injection molding is preferred, while hand lay-up suits simpler, custom or low-volume parts.

Surface Finish and Product Quality

Injection molding offers superior surface finish and consistent product quality due to precise control over resin flow and mold conditions, resulting in smooth, defect-free surfaces ideal for high-volume production. Hand lay-up techniques tend to produce products with more surface irregularities and variability in quality, as manual application can lead to air bubbles, resin-rich or dry areas, and uneven textures. The enhanced finish and dimensional accuracy of injection molded components make them preferable for applications demanding tight tolerances and aesthetic appeal.

Environmental and Waste Considerations

Injection molding generates less waste due to precise resin usage and closed systems that reduce emissions, making it more environmentally friendly than hand lay-up. Hand lay-up often produces excess resin runoff and scrap materials, leading to higher environmental impact and disposal challenges. Efficient recycling and advanced waste management are critical for minimizing the ecological footprint in both methods.

Choosing the Right Process for Your Resin Product

Injection molding offers high precision and repeatability, making it ideal for producing complex resin products with tight tolerances. Hand lay-up is better suited for low-volume, large-scale parts where customization and flexibility are priorities. Consider production volume, design complexity, and budget to select the most efficient resin fabrication method.

Injection Molding vs Hand Lay-Up Infographic

materialdif.com

materialdif.com